System for evaluating liquid foaming performance

A liquid and performance technology, applied in the system field of evaluating the foaming performance of liquid, can solve the problems that are not suitable for analyzing and studying the foaming performance of wet desulfurization slurry, and achieve the effect of simple operation and intuitive phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

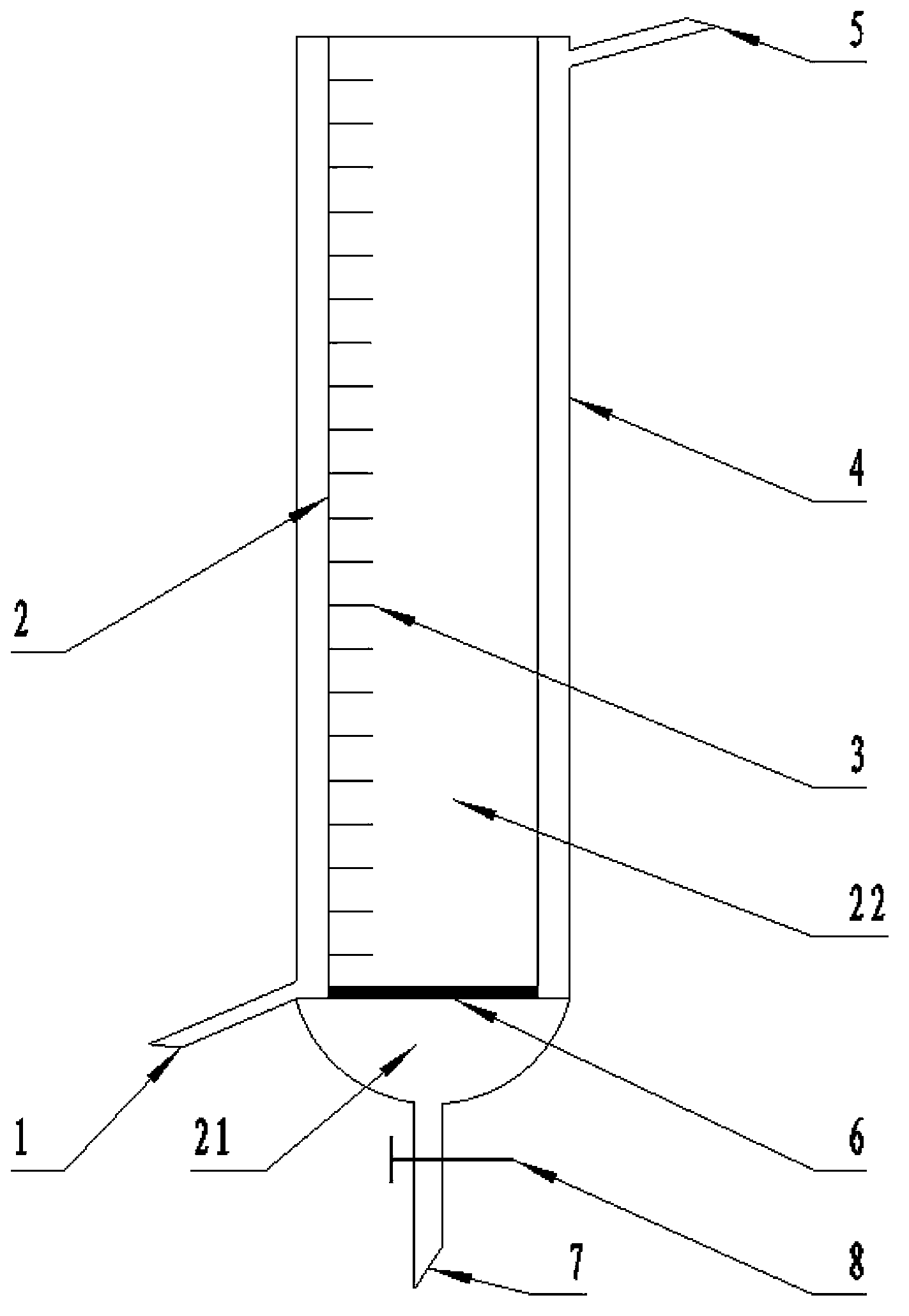

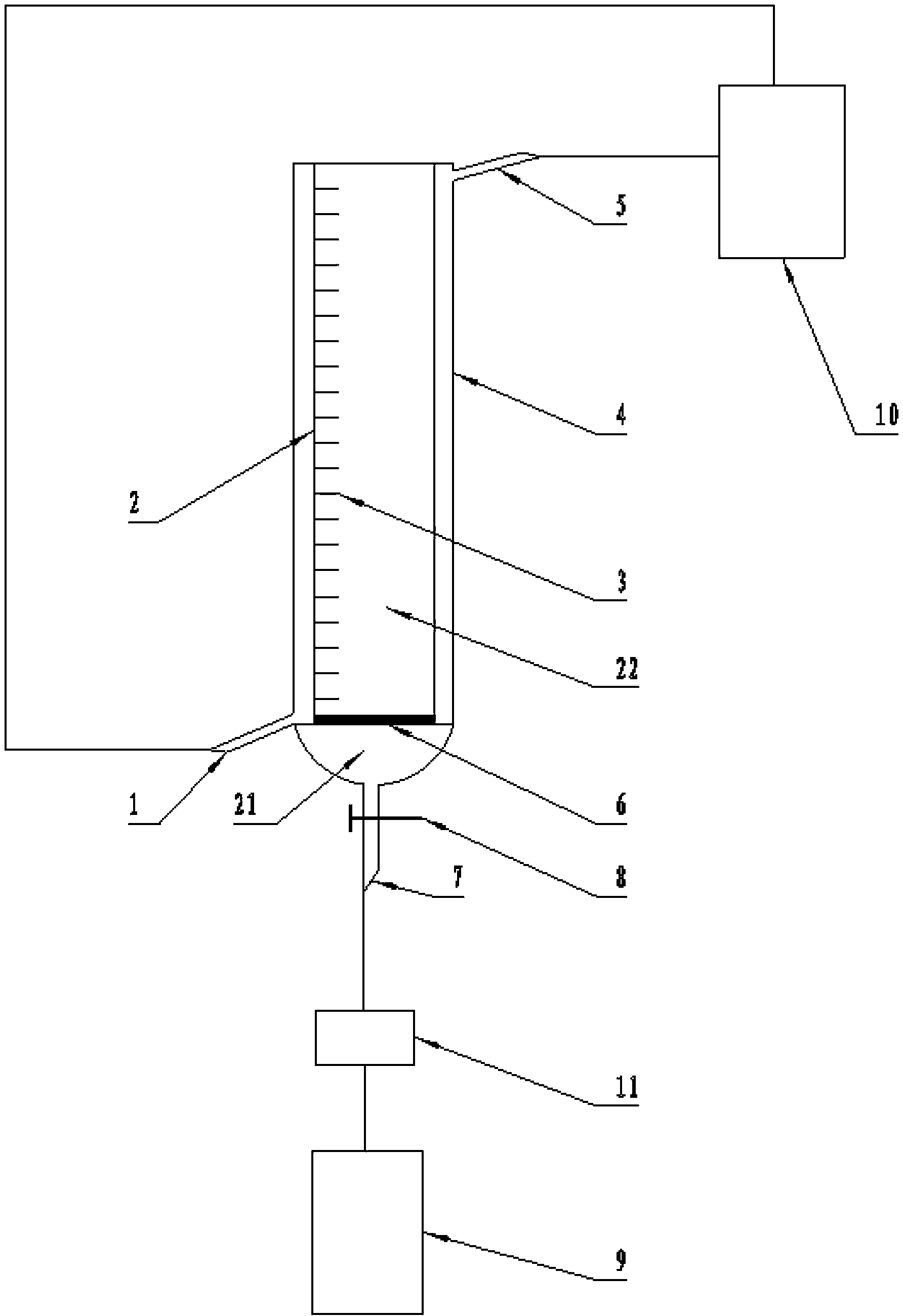

[0020] The system for evaluating the foaming performance of a liquid according to the present invention will be described in detail below with reference to the accompanying drawings. A system for evaluating the foaming performance of a liquid, the system for evaluating the foaming performance of a liquid includes a device for evaluating the foaming performance of a liquid, the device for evaluating the foaming performance of a liquid includes a transparent first Cylinder body 2, the bottom end of the first cylinder body 2 is closed, the top end of the first cylinder body 2 is open, and a filter plate 6 is sealed and connected inside the first cylinder body 2, and the filter plate 6 can divide the inside of the first cylinder body 2 into The upper cavity 21 and the lower cavity 22 are arranged up and down, and the upper cavity 21 and the lower cavity 22 are independent of each other. The bottom end of the first cylinder 2 is provided with an air inlet 7. The system for evaluatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com