Bottle support mechanism and filling machine

A filling machine and bottle supporting technology, which is applied in bottle filling, packaging, liquid bottling, etc. It can solve the problems of many wearing parts, high cost, and complex structure of the lifting device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

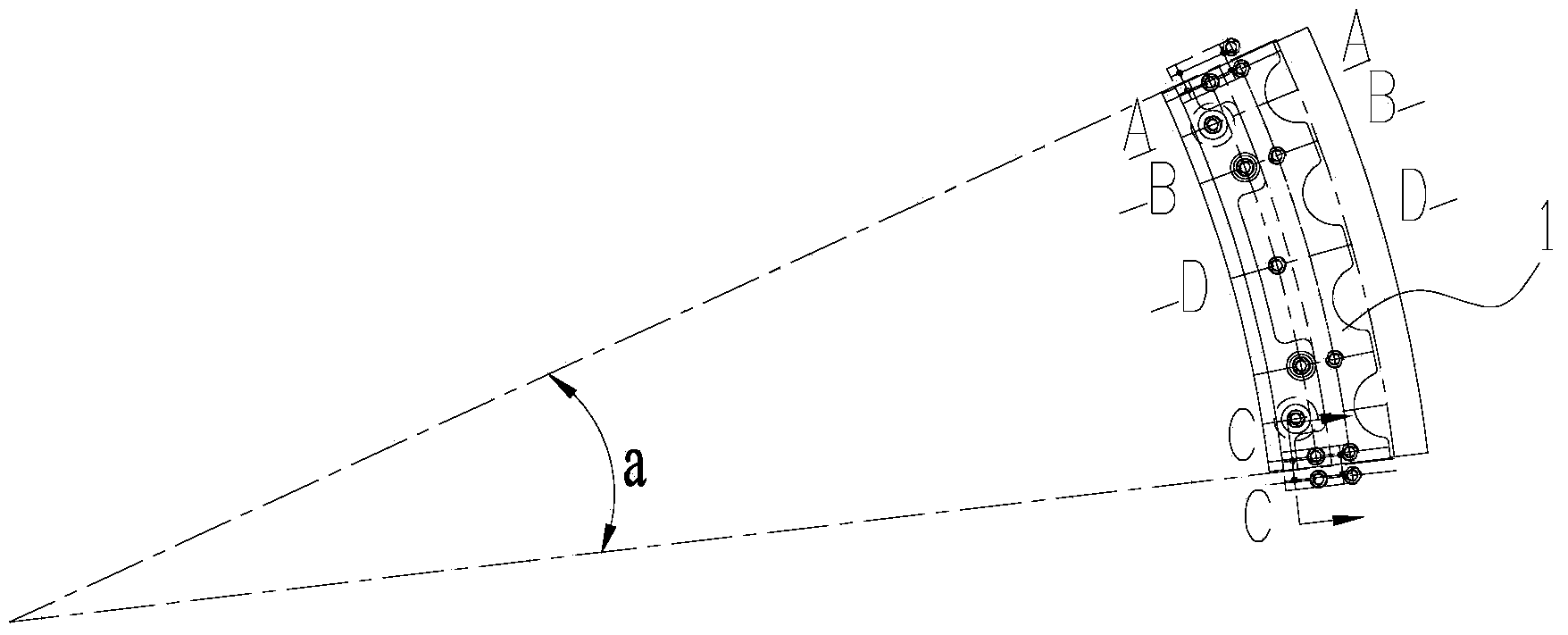

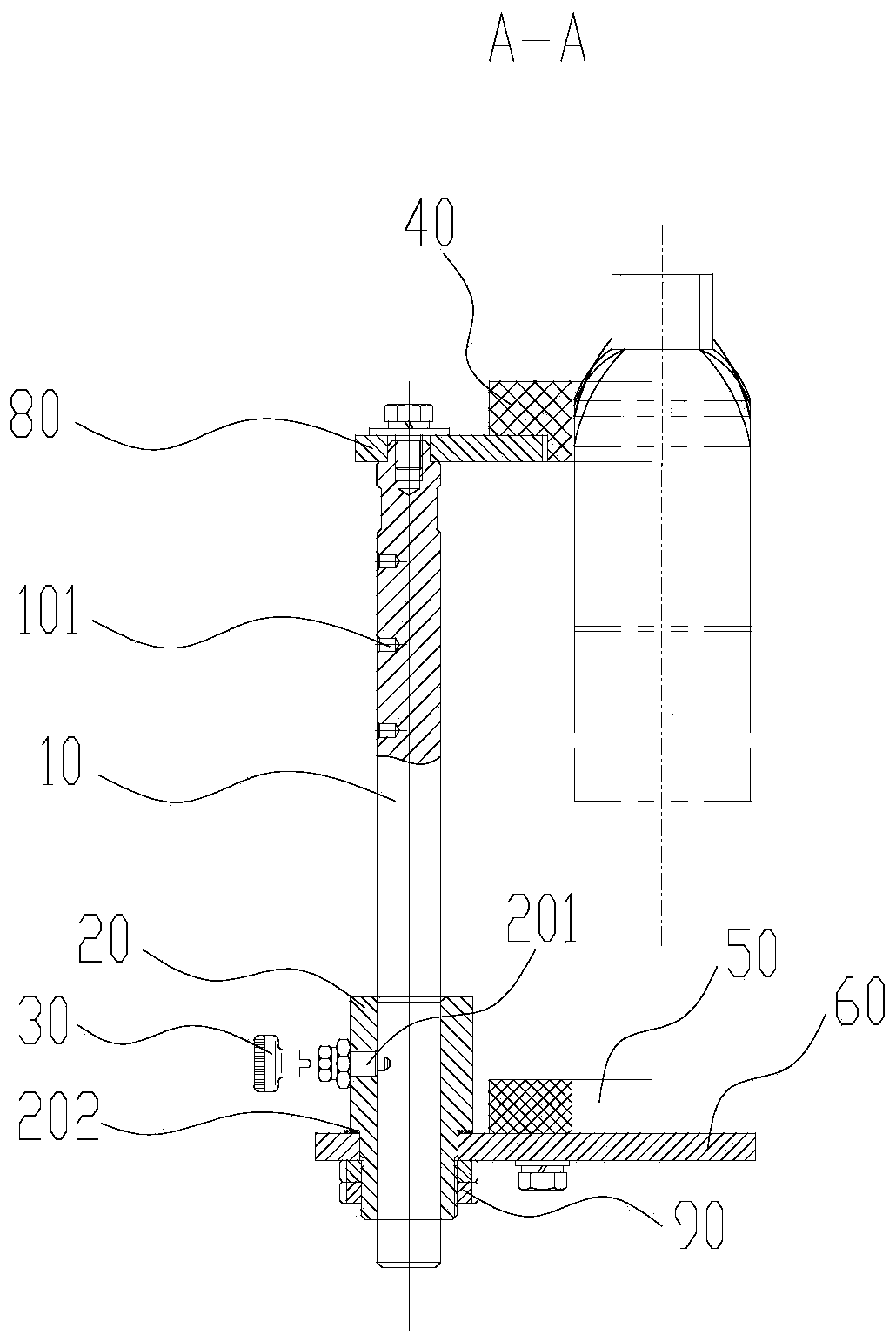

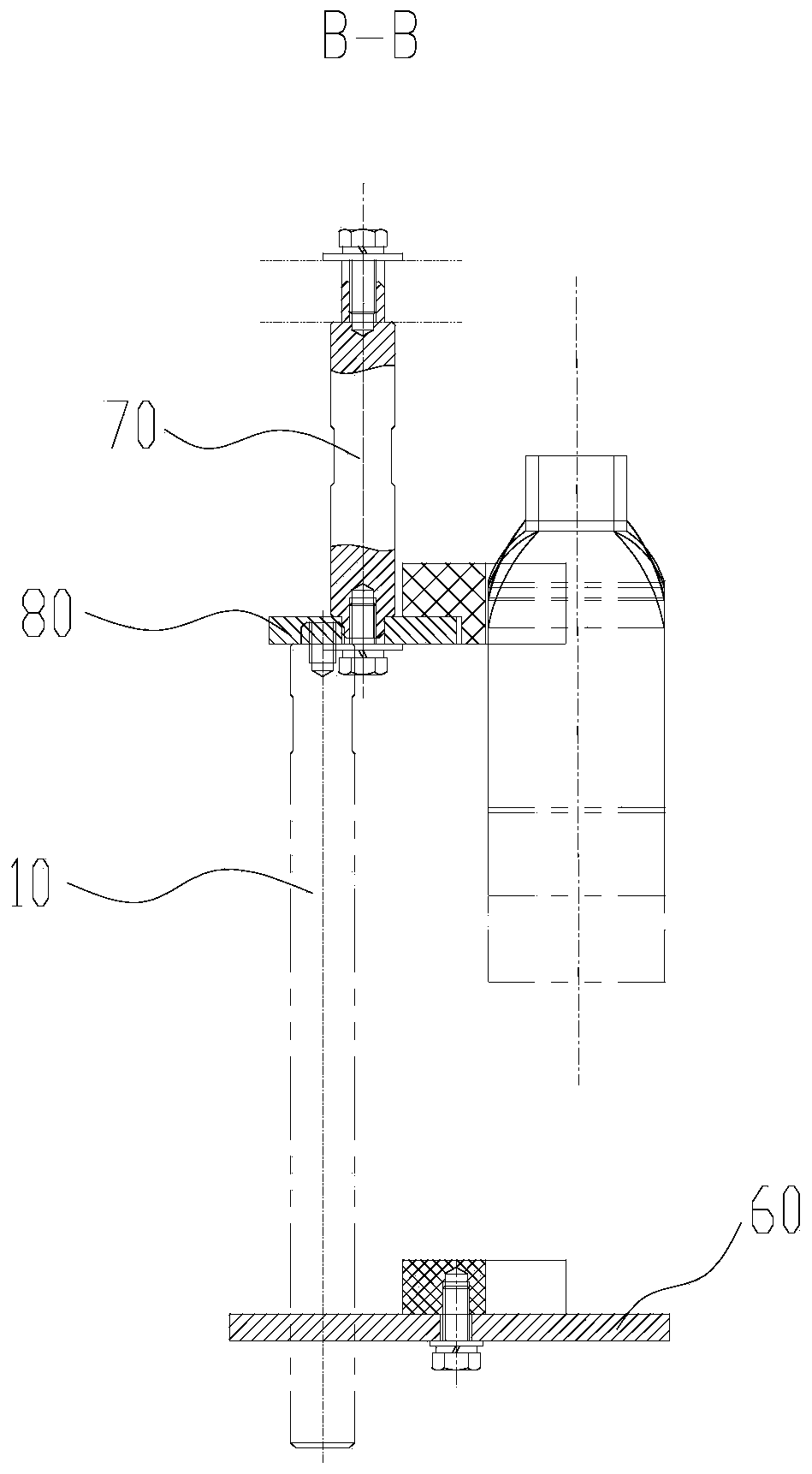

[0025] Such as Figure 1 to Figure 5 Shown, a kind of bottle support mechanism 1 comprises support column 10, guide nut 20, indexing pin 30, upper bottle guard plate 40, lower bottle guard plate 50, bottle support plate 60, and described support column 10 is provided with filling The mounting plate 2 of the loading port 210 is connected, and the outer wall of the supporting column 10 is provided with a plurality of first pin holes 101 along its axial direction, and the second pins matching the first pin holes 101 are arranged on the guide nut 20 hole 201, the indexing pin 30 cooperates with the second pin hole 201 and one of the first pin holes 101 to fix the guide nut 20 on the support column 10, and the upper bottle protection plate 40 is connected with the upper end of the support column 10, The bottle supporting plate 60 is connected with the guide nut 20 , and the lower bottle protecting plate 50 is fixed on the upper end surface of the bottle supporting plate 60 and corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com