A cluster type material line

A clustering and material sorting technology, which is applied to the types of packaging items, impact-sensitive items, packaging, etc., can solve the problems of restricting the promotion of production and application of equipment, the accumulation of pressure on the center of gravity of multi-layer materials, and the unreliability of technology maturity. The effect of market promotion application and prospect, saving equipment cost and floor area, and avoiding conflict troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

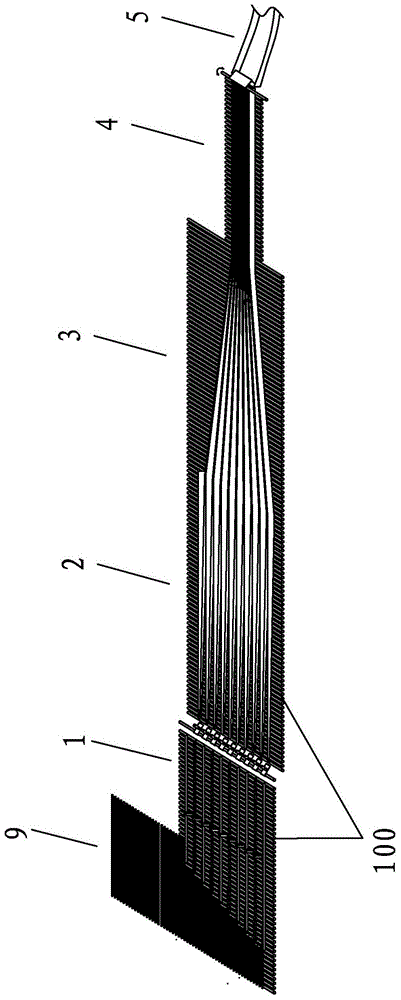

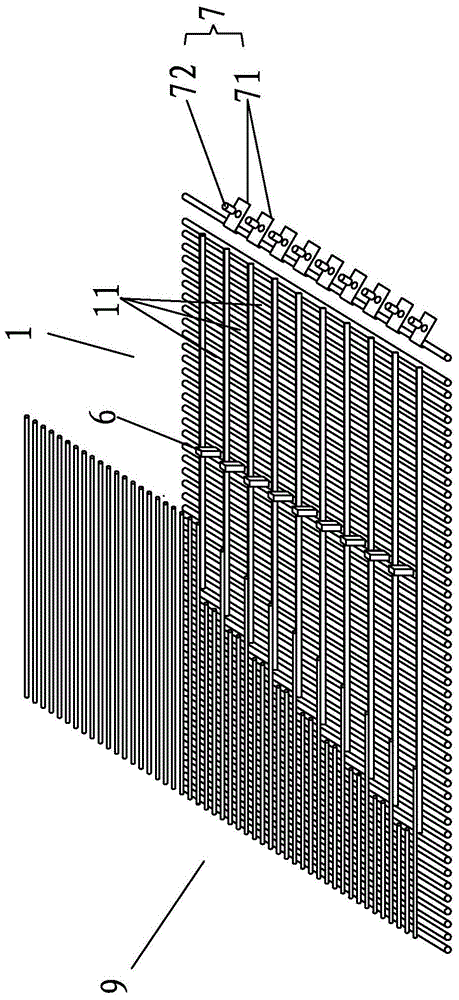

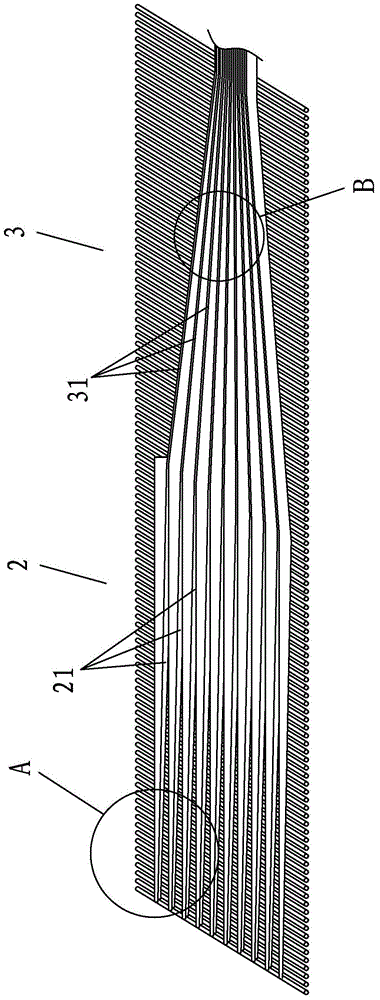

[0040] The present invention relates to a kind of cluster type material management line, such as figure 1 Shown, be located at the side of product total delivery platform 9. The total conveyor table 9 is used to convey the products to be packaged, such as applied to tile packaging, and the total conveyor table 9 conveys the tiles to be packaged that are released from the kiln. The material sorting line of the present invention mainly includes a material sorting conveying platform 100 and a shunting section 1 , a brick changing section 2 and a clustering section 3 arranged sequentially on the material sorting conveying platform 100 toward its conveying direction. The material sorting conveyor 100 is used to provide power for tile flow conveying and sorting, and its structure can have various types, such as roller conveyor (given example), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com