Cell analyzer and its cleaning system

A technology of cleaning system and analyzer, which is applied in the field of medical inspection, can solve the problems of low cleaning utilization rate and achieve the effect of improving cleaning efficiency and cleaning agent utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

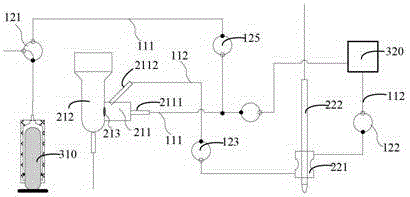

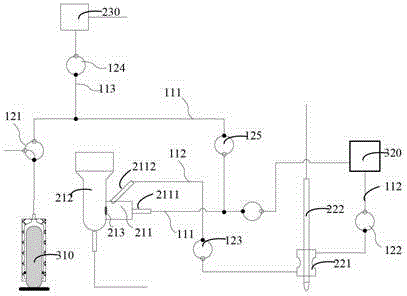

[0024] Such as figure 1 As shown, a cleaning system for a cell analyzer includes a back tank cleaning part, a fluid power source 310 and at least one functional unit cleaning part.

[0025] The rear pool cleaning part is provided with a rear pool inlet 2111 and a rear pool outlet 2112. The rear tank inlet 2111 allows cleaning agents such as diluents to enter the rear tank 211 for cleaning; the rear tank outlet 2112 allows the cleaning agent after cleaning the rear tank 211 to flow out of the rear tank 211.

[0026] The fluid power source 310 communicates with the rear tank inlet 2111 through a rear tank cleaning pipeline 111, and the rear tank cleaning pipeline 111 is provided with a first control valve 121. The fluid power source 310 is used to provide the flow power of the cleaning agent, and a syringe or the like can be used. Since the cell analyzer itself is mostly provided with fluid power components such as syringes, the fluid power source 310 can also share the syringe of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com