Device for testing stress-strain of plastic concrete/mortar and use method of device

A plastic concrete, stress-strain technology, applied in the field of civil engineering, to achieve the effect of improving test accuracy and ensuring changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

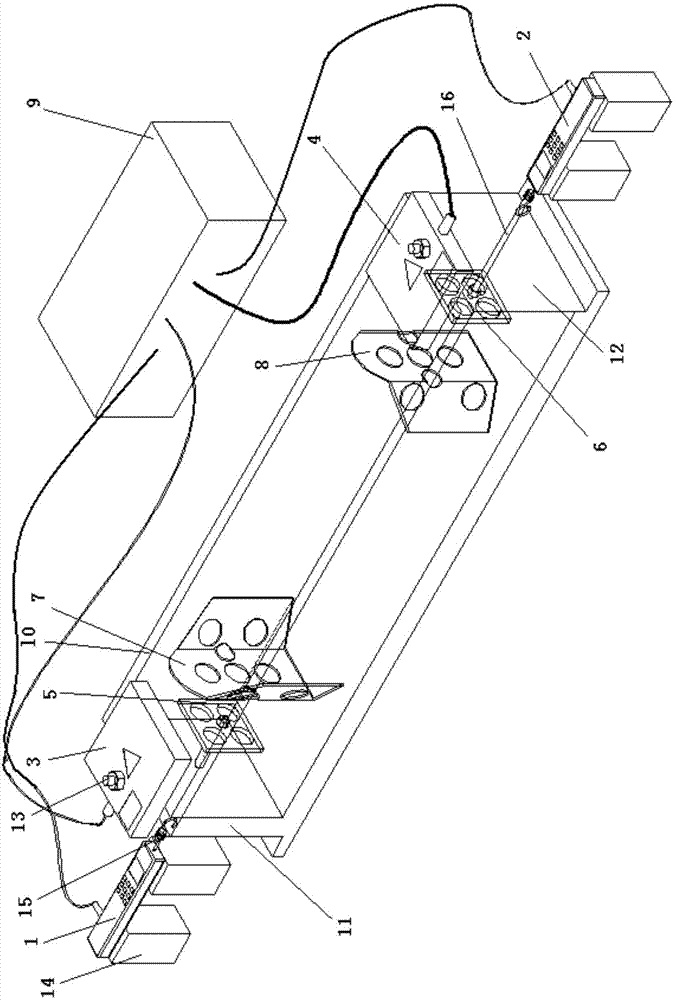

[0043] Such as figure 1 As shown, a device for testing the stress-strain of plastic concrete / mortar, the device includes a dynamometer a1, a dynamometer b2, a laser displacement sensor c3, a laser displacement sensor d4, a force transmission unit, a laser target unit, and a data collector 9 and the mold 10, the left and right sides of the mold 10 are respectively equipped with a dynamometer a1 and a dynamometer b2, the laser target unit and the force transmission unit are all arranged in the inner cavity of the mold 10, and the left and right ends of the top of the mold 10 are respectively equipped with The laser displacement sensor c3 and the laser displacement sensor d4, and the data collector 9 are respectively connected to the dynamometer a1, the dynamometer b2, the laser displacement sensor c3 and the laser displacement sensor d4 through circuits.

[0044] The laser target unit includes a laser target e7 and a laser target f8 , wherein the laser target e7 and the laser ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com