Plug-in assembled water well drilling rig

A water well drilling rig, assembled technology, applied in the direction of rotary drilling rig, percussion drilling, rotary drilling, etc., can solve the problems of inability to transport, unfavorable transport, heavy weight, etc., to facilitate transport, reduce labor intensity, fast The effect of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

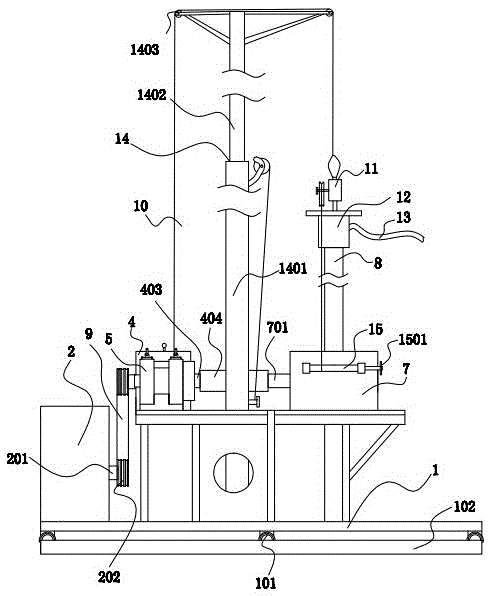

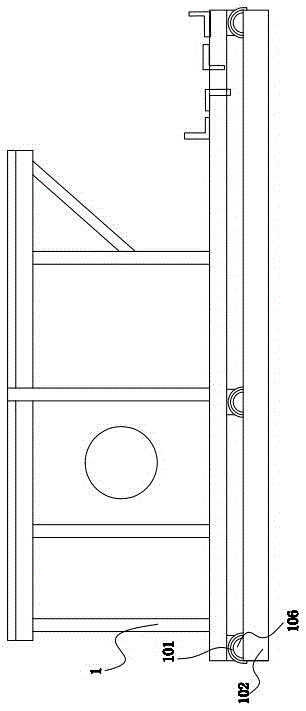

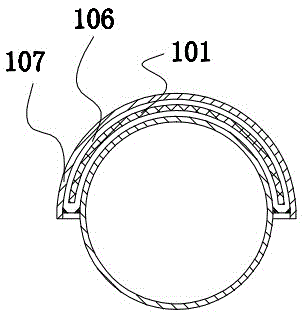

[0025] See attached Figures 1 to 10 , the plug-in assembled water well drilling rig in the figure includes a frame 1 made of channel steel and / or angle iron, a power source 2 fixed on the frame 1, a gearbox 4, a hoist 5, a rotary head 7 and The tower 14 and the main drilling rod 8 located in the rotary head 7 are fixedly wound with a suspension stay rope 10 on the winch of the hoist 5, and one end of the suspension stay rope 10 passes through the guide wheel on the tower 14 and is fixed. On the lifter, the lifter is connected with the lifter head 11, a water tap 12 is fixed below the lifter head 11, and a water pipe 13 for drilling fluid diversion is installed on the water tap 12, and the main drill pipe 8 The rod body is inserted into the rotary head 7 and its rotation is controlled by the rotary head 7; it is characterized in that: the power source 2, hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com