Method for producing direct reduced iron using carbon-containing pellets

A carbon pellet and reduced iron technology, applied in the field of reduced iron production, can solve the problems of thin carbon-containing pellet material layer, inability to achieve large-scale mass production, low utilization rate of gas heat energy, etc. Improve the utilization rate of raw materials and equipment utilization, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

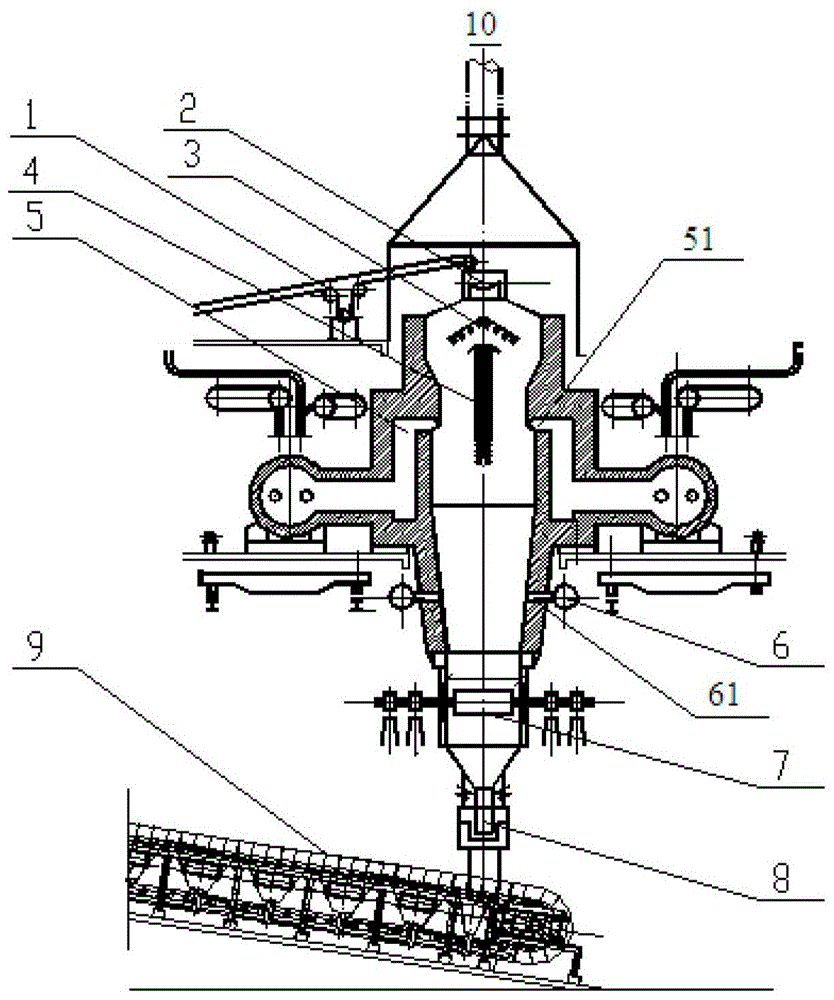

[0032] The method for producing direct reduced iron by using carbon-containing pellets according to the present invention will be further described below based on specific examples and accompanying drawings, but this description does not constitute an improper limitation to the technical solution of the present invention.

[0033] figure 1 It shows the implementation process of the method for producing direct reduced iron using carbon-containing pellets according to the present invention.

[0034] Such as figure 1 As shown, the shaft furnace 10 includes from top to bottom: a distributor 2, a drying bed 3, a belt conveyor 1, an air guide wall 4, a combustion chamber 5 and a nozzle 51, a cooling pipe 6 and an inlet 61, and a toothed roller unloader 7. Vibrating unloader 8 and conveyor 9; in addition, it also includes a batching room with a raw material bin, a batching machine and a metering device, a mixing machine, and a pelletizing machine (not in figure 1 shown in ).

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com