Baking tray and baking grill thereof

The technology of a grill and baking pan is applied in the field of food processing appliances, which can solve the problems of unfavorable food full heating, unfavorable oil dripping and food residue cleaning, unsatisfactory baking effect, etc., and achieves simple and reasonable structure, good grilling effect, and convenient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

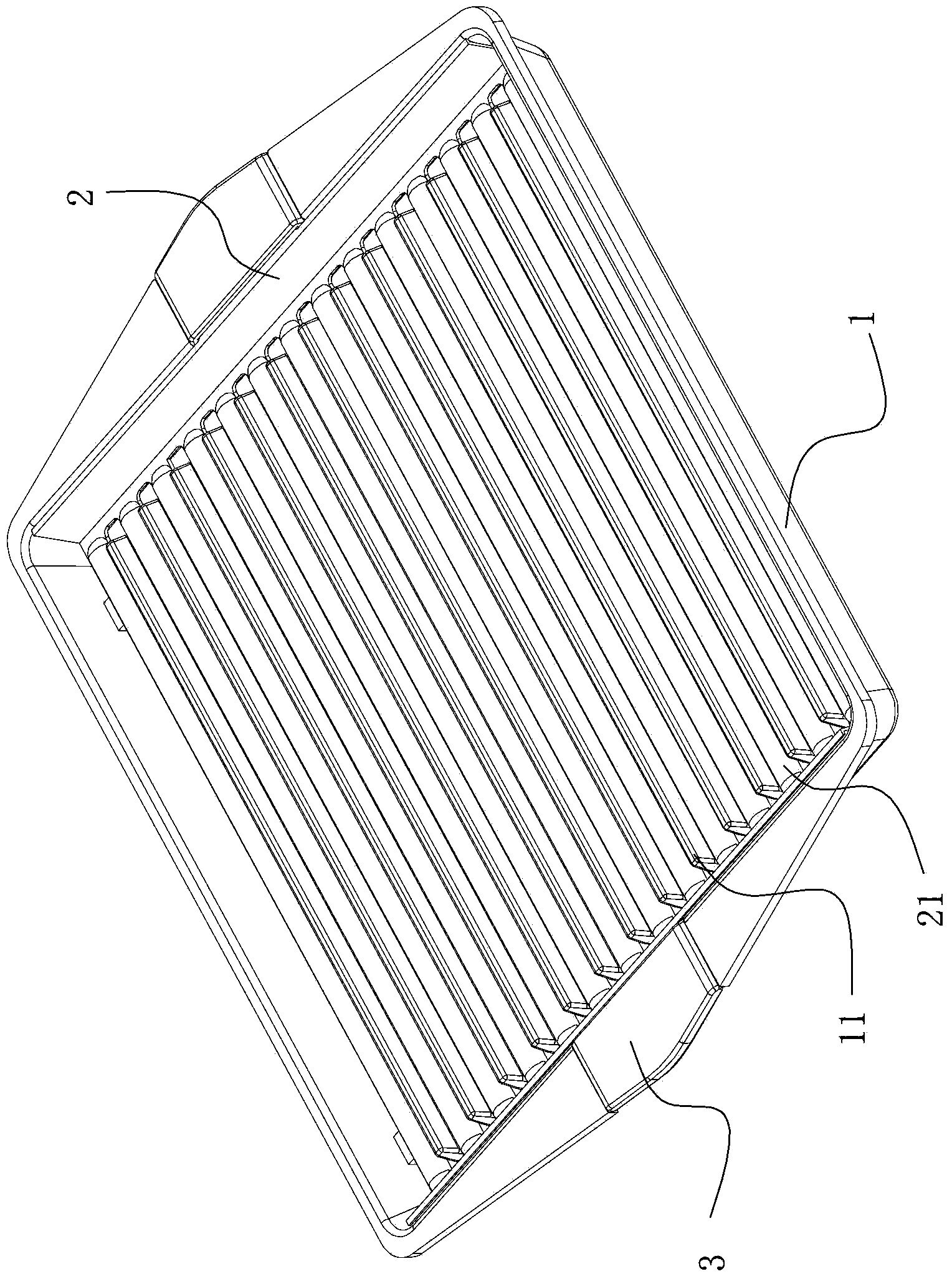

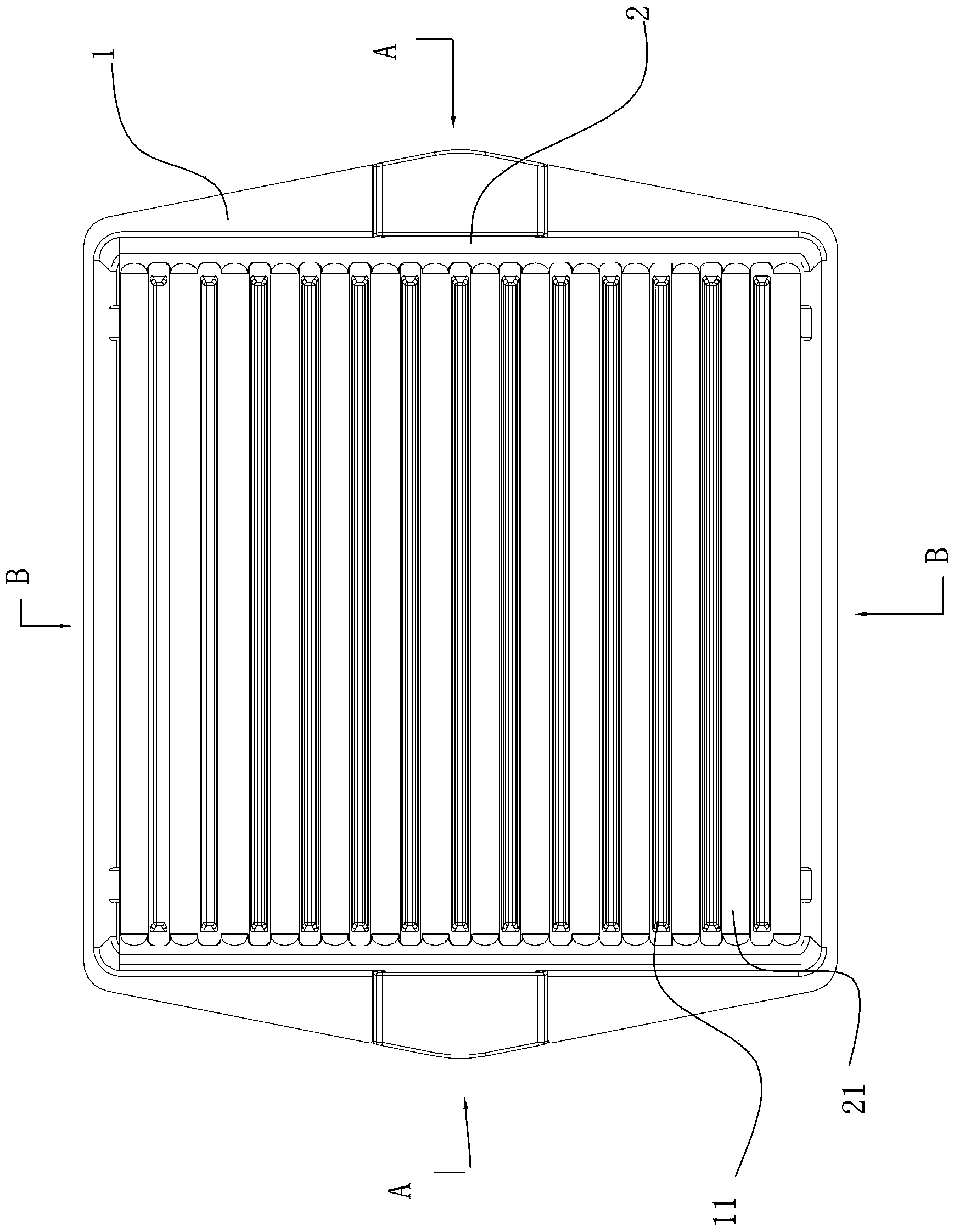

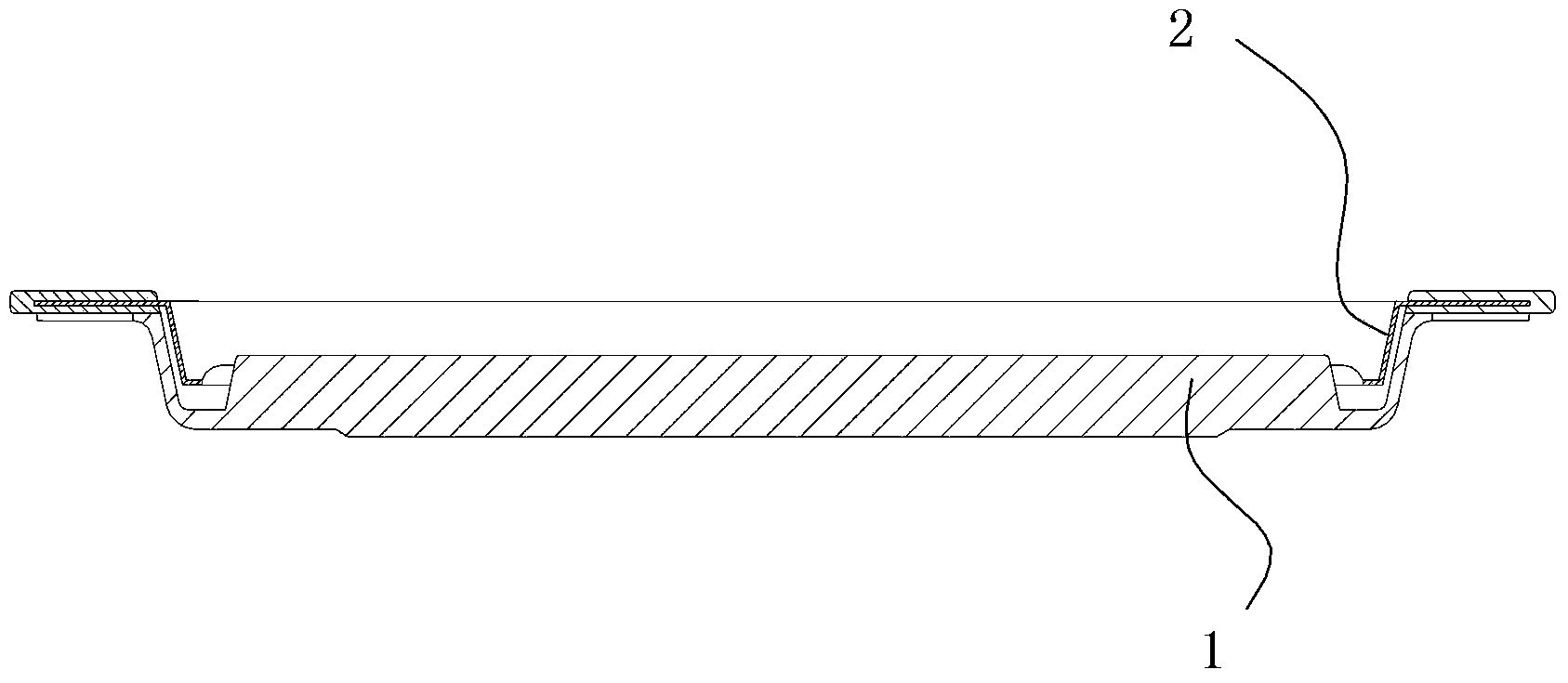

[0031] Such as Figure 1~5 As shown, the baking pan of this embodiment includes a pan body 1 of the pan. The pan body 1 is square, and a grill 2 is set on the bottom surface of the pan body 1. The grill 2 is also square. A straight strip-shaped shelf bar 21 is evenly spaced and arranged in parallel. The cross section of the shelf bar 21 presents an arc-shaped protrusion. The shelf bar 21 is close to the bottom surface of the baking tray body. Strip-shaped convex strips 11, the convex strips 11 are evenly spaced and arranged in parallel, and the convex strips 11 pass through the slots 23 between the rest strips 21 to extend out of the grill 1 to form a grill surface; the upper surface of the convex strips 11 is the same plane , when the grill 2 is erected in the tray body 1, the upper surface of the protruding strip 11 is higher than the shelf bar 21, and the four corners of the bottom surface of the tray body 1 are respectively provided with support blocks 12 for supporting th...

Embodiment 2

[0034] Such as Figure 6 , 7 As shown, the pan body 1 of the baking pan in this embodiment is an elliptical main part, and the grill 2 is also a corresponding elliptical main part, and the rest are the same as in the first embodiment.

Embodiment 3

[0036] Such as Figure 8 As shown, the pan body 1 of the grill pan of this embodiment is an elliptical main body part, and the convex line 11 on the pan body 1 is S-shaped, and the grill 2 is also a corresponding oval main body part, and the shelving on the grill 2 Bar 21 is also a corresponding S-shape, and the rest are the same as in Embodiment 1.

[0037] Of course, this implementation example only describes the straight and S-shaped shelving bars 21, and the shelving bars 21 can also be designed in other shapes, and the principle is similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com