Ground lead

A grounding wire and grounding clip technology, which is applied in the direction of clips connecting conductors, multi-core cable end parts, etc., can solve the problems of large body inclination angles, low operating efficiency of grounding wires, safety risks, etc. The effect of greatly tilting the risk, improving labor efficiency, and avoiding personal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

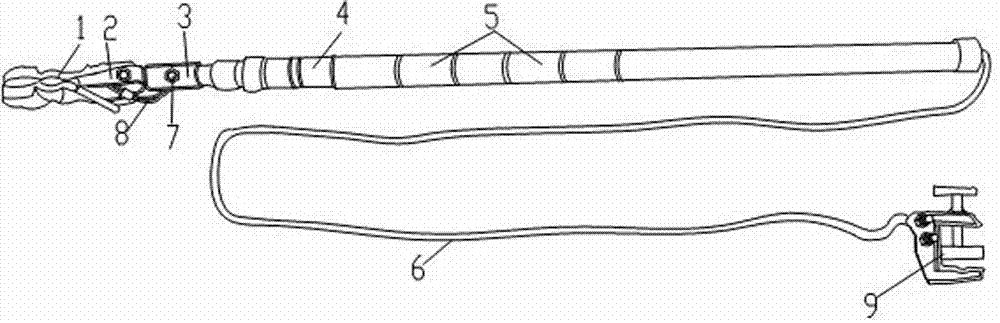

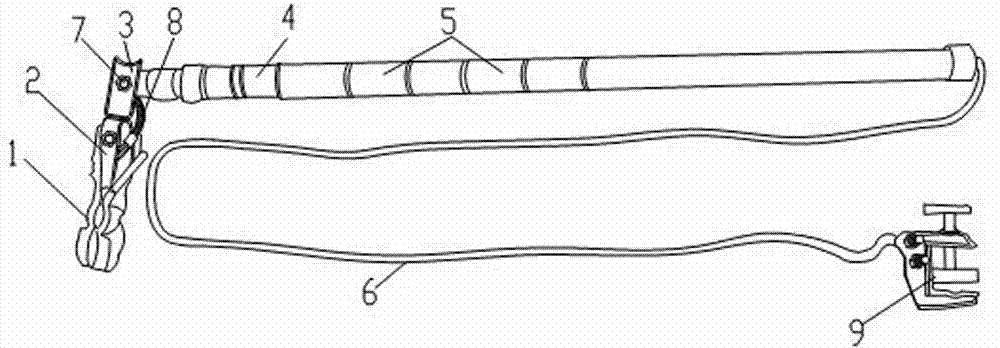

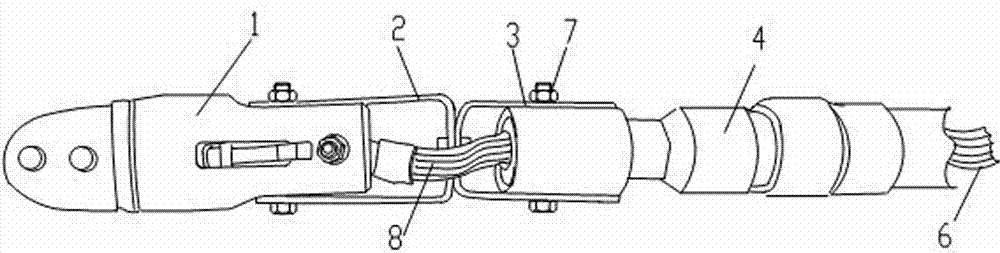

[0018] Embodiment 1: A grounding wire, including a retractable insulating rod 4, a duckbill type impact wire clamp 1, a ground soft copper wire 6 and a ground wire clamp 9; the ground soft copper wire 6 passes through the stretchable insulating rod 4 The inner hole, its left end is connected with the duckbill type impact wire clamp 1, and the right end is connected with the ground wire clamp 9, and the described duckbill type impact wire clamp 1 is hinged between the left end of the flexible insulating rod 4 through the connector, and set There is a locking mechanism; the left end of the ground soft copper wire 6 protrudes from the inner hole of the left end of the telescopic insulating rod 4 to connect with the duckbill type impact clamp 1 . The connectors are a U-shaped left connecting piece 2 and a U-shaped right connecting piece 3; the open end of the U-shaped left connecting piece 2 is fixedly connected with a duckbill type impact clamp 1 through bolts, and the U-shaped le...

Embodiment 2

[0020] Embodiment 2: A grounding wire, including a retractable insulating rod 4, a duckbill type impact wire clamp 1, a ground soft copper wire 6 and a ground wire clamp 9; the ground soft copper wire 6 passes through the stretchable insulating rod 4 The inner hole, its left end is connected with the duckbill type impact wire clamp 1, and the right end is connected with the ground wire clamp 9, and the described duckbill type impact wire clamp 1 is hinged between the left end of the flexible insulating rod 4 through the connector, and set There is a locking mechanism; the left end of the ground soft copper wire 6 protrudes from the inner hole of the left end of the telescopic insulating rod 4 to connect with the duckbill type impact clamp 1 . The connectors are a U-shaped left connecting piece 2 and a U-shaped right connecting piece 3; the open end of the U-shaped left connecting piece 2 is fixedly connected with a duckbill type impact clamp 1 through bolts, and the U-shaped le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com