Graphene array composite positive electrode and its preparation method and application

A graphene array, composite cathode technology, applied in battery electrodes, nanotechnology for materials and surface science, electrical components, etc. Poor stability and other problems, to achieve the effect of excellent cycle performance, fast electron transfer and charge transfer, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

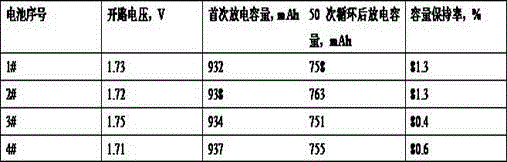

Examples

Embodiment 1

[0037] A 30 μm thick nickel current collector is placed in the quartz glass tube of a tubular resistance furnace, and a 1000 sccm mixture of argon and hydrogen is introduced, where the volume ratio of hydrogen is 1%, and the temperature is raised to 650 ° C at the same time; the voltage is adjusted to 10 kV, Generate a stable glow plasma to remove impurities on the surface of the substrate. After 10 minutes, feed 150 sccm methane and 1350 sccm argon, and feed water vapor at the same time, control the relative humidity at 40%, then stop feeding the mixed gas of argon and hydrogen, and react for 20 min , and then lower the temperature to room temperature in a reducing atmosphere to prepare a graphene array.

Embodiment 2

[0039]Use a metal titanium substrate, attach iron powder on its surface, place it in a chemical vapor deposition chamber, and seal it; apply a magnetic field in the vertical direction of the substrate, the magnetic field strength is 0.01T, and pass 50 sccm argon gas for 30 minutes to remove oxygen in the reaction chamber, and heat the lining The temperature was lowered to 700°C, and then 100 sccm of methane was introduced and kept for 1 hour. After the reaction, stop heating, turn off the methane, and cool to room temperature under the protection of argon. The product was taken out, washed with 1mol / L hydrochloric acid, and dried to obtain a graphene array.

Embodiment 3

[0041] The prepared graphene array and elemental sulfur were put into a tube furnace at a mass ratio of 1:10, heated to 155° C., and kept for 10 h under nitrogen gas to form a sulfur-loaded graphene array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com