Test method and test device for gear tooth root bending fatigue durability

A technology of bending fatigue and testing method, which is applied to the testing device implementing the above method, and the field of gear tooth root bending fatigue durability testing, can solve the problems of narrow pasting space, difficult lead wires, and difficult to accurately determine the pasting position, and achieves a simple structure. , easy to operate, accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with specific embodiments.

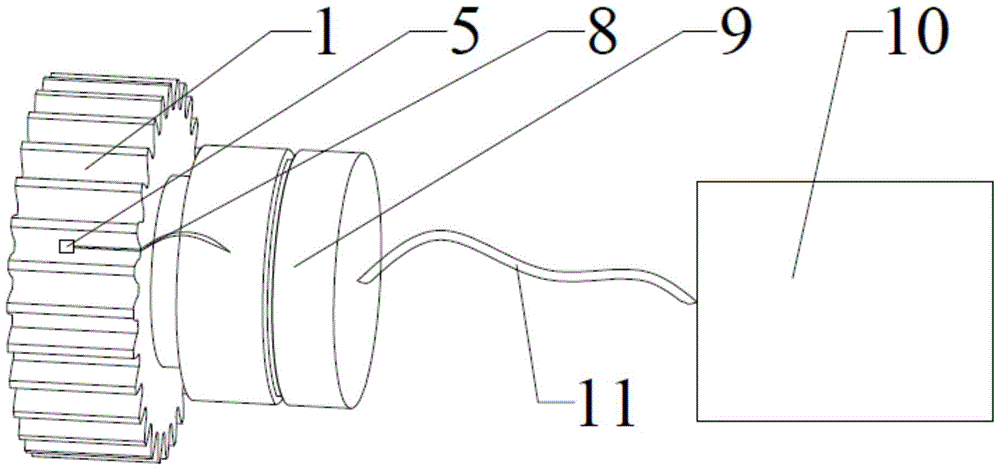

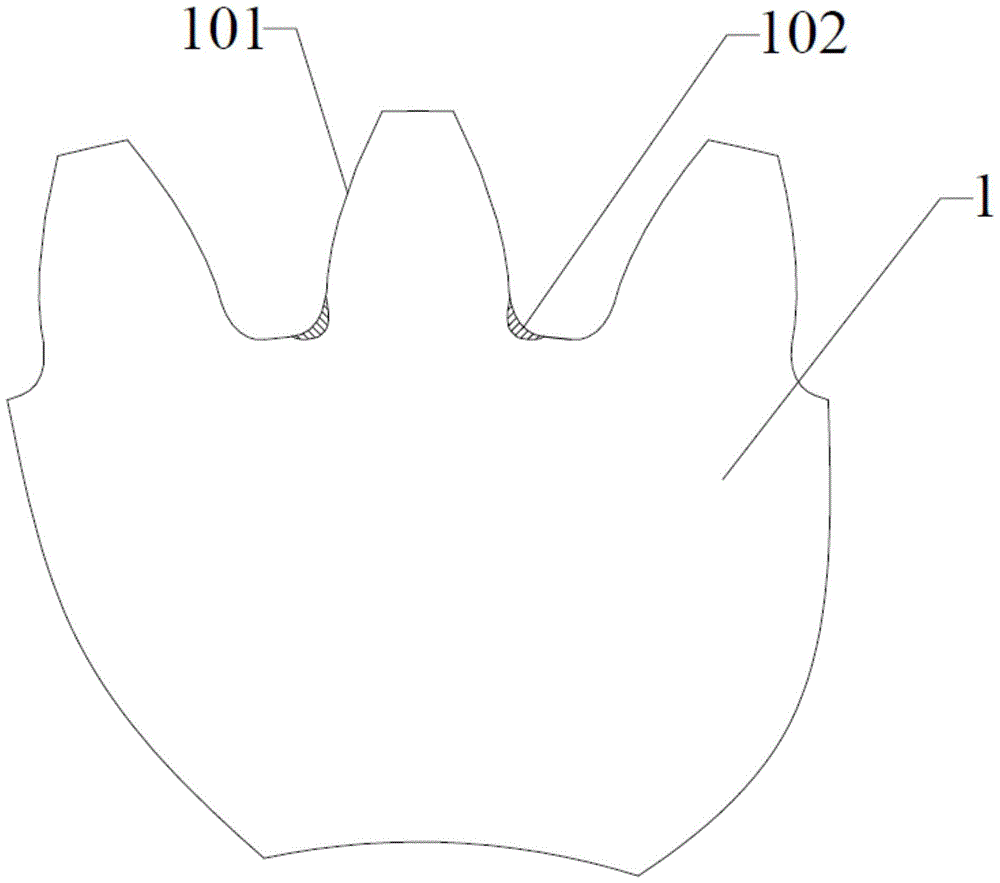

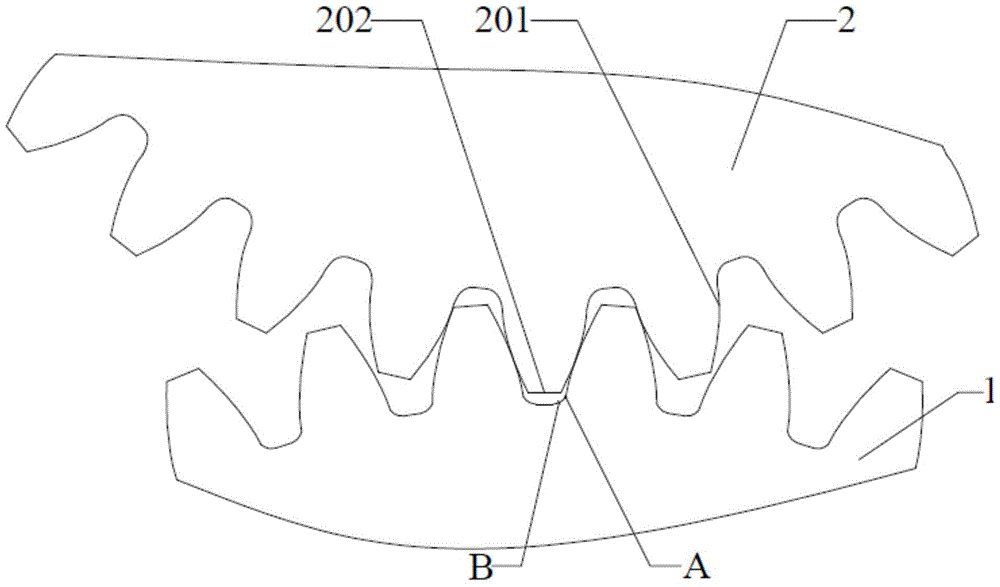

[0053] The invention provides a gear tooth root bending fatigue durability test device, such as figure 1 As shown, it includes a strain gauge 5 attached to the tooth root of the gear to be tested 1 and a pressing piece 7 that is adapted to the shape of the gear to be tested 1. The pressing piece 7 is pressed into the tooth groove of the gear to be tested 1, and the pressing piece 7 is A silicone rubber pad 6 is arranged between the measuring gear 1; it also includes a patch template 4 fitted on the tooth surface of the gear to be measured 1; the strain gauge 5 is connected to the slip ring 9 through a lead 8 and the slip ring 9 is connected with a strain through a wire 11 仪10.

[0054] The present invention also provides a method for testing gear tooth root bending fatigue durability. The method uses the above-mentioned testing device for testing, and specifically includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com