Boiler bottom support structure

A boiler bottom and support structure technology, applied in the direction of boiler support/positioning device, etc., can solve the problem that the support structure cannot be applied, and achieve the effect of good support, firm structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

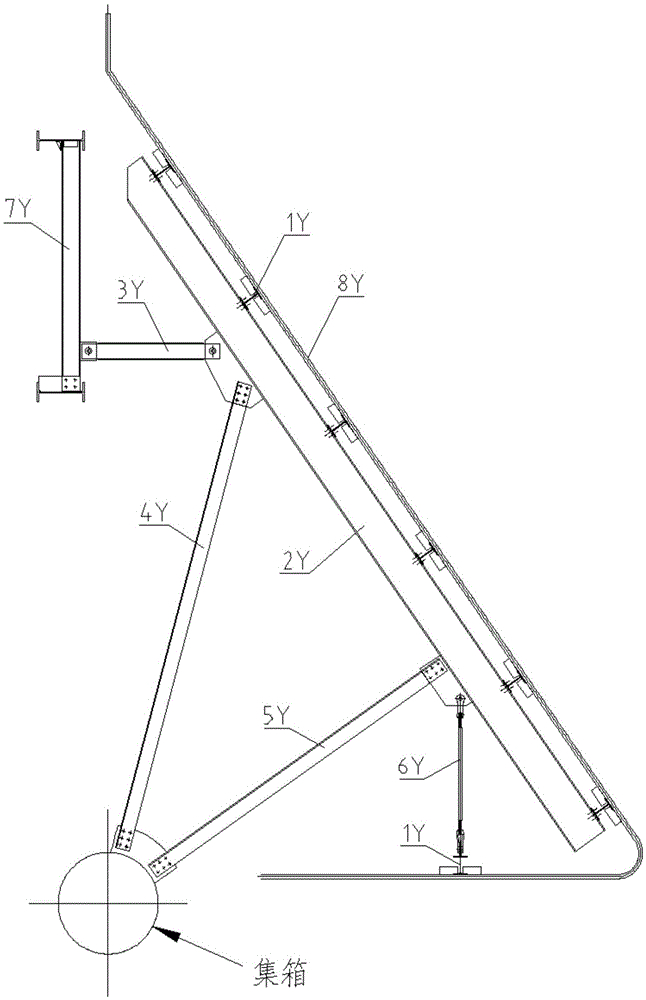

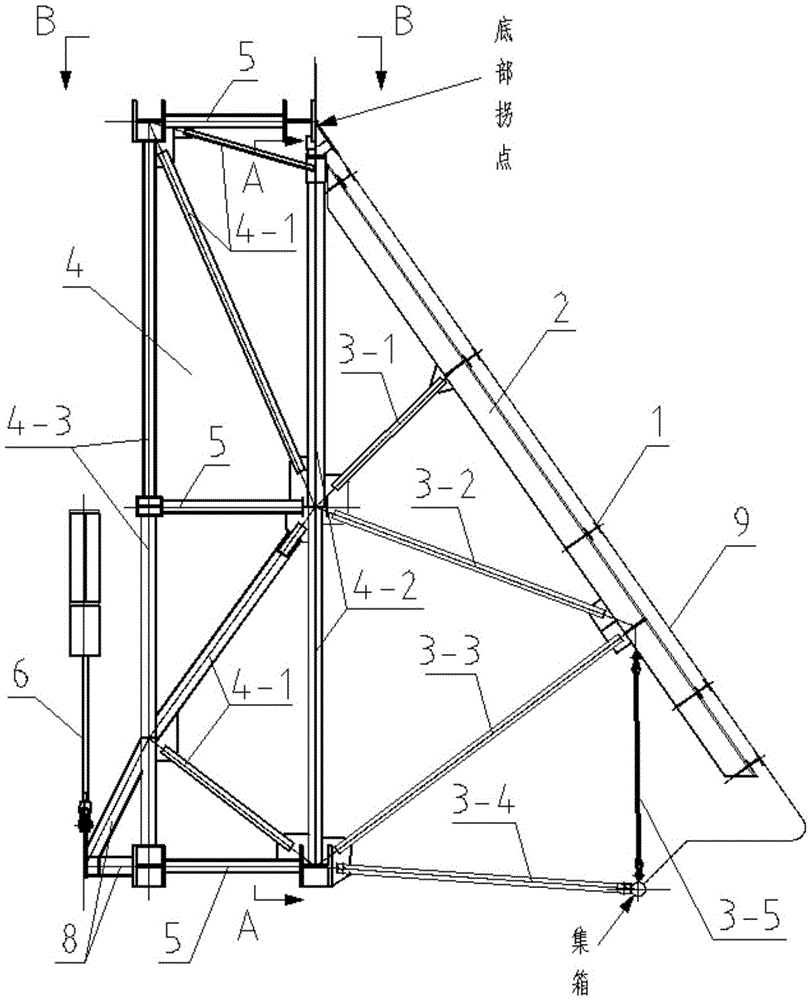

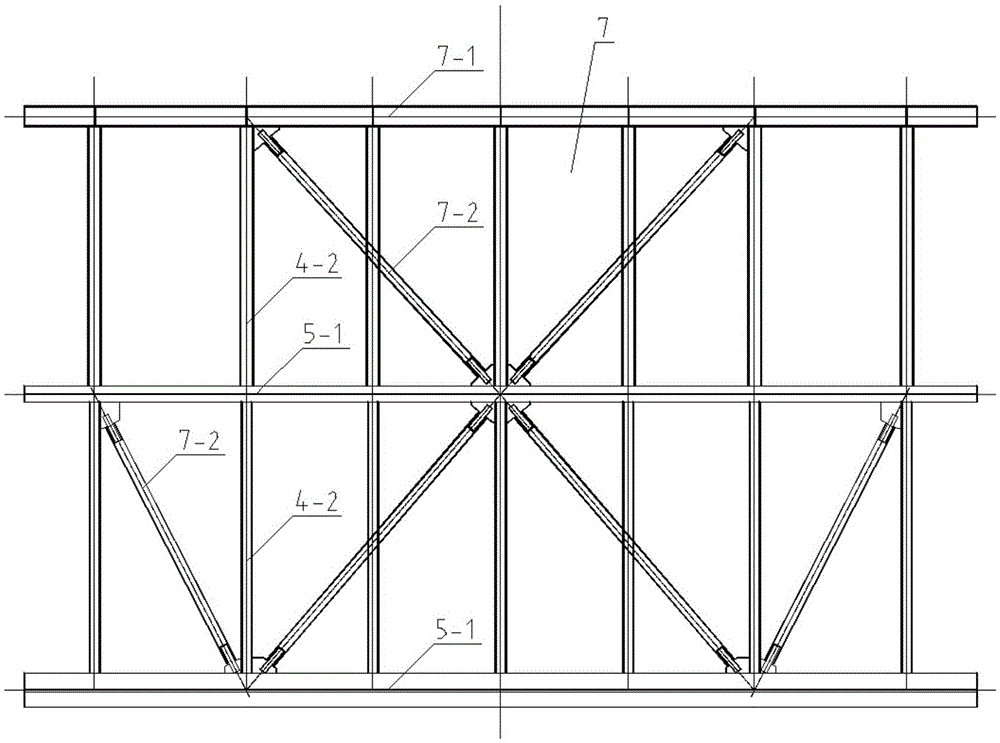

[0022] Such as figure 2 Shown is a structural schematic diagram of a boiler bottom support structure provided by the present invention. First, a plurality of horizontal rigid beams 1 are arranged along the bottom tube wall 9 of the second boiler, and the upper flange of the horizontal rigid beam 1 is stuck on the bottom tube wall 9 of the boiler; vertical beams 2 are arranged close to the lower flange of the horizontal rigid beam 1, and the vertical The lower flange of the beam is supported by multiple diagonal braces, respectively 3-1, 3-2, 3-3, 3-5, of which 3-5 acts on the bottom header of the boiler; there are three levels of horizontal bracing arranged along the height direction of the bottom of the boiler. Truss 5; the horizontal trusses on the lower floor are provided with connecting rods 3-4 to connect with the header at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com