Valley current steam boiler adopting heat condition oil to transfer heat and method for preparing steam

A technology of heat-conducting oil and steam, applied in the field of electric steam boilers, can solve the problems of high energy costs and achieve high energy storage efficiency, good economic benefits, and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better explain the present invention, the present invention will be further explained below in conjunction with the examples.

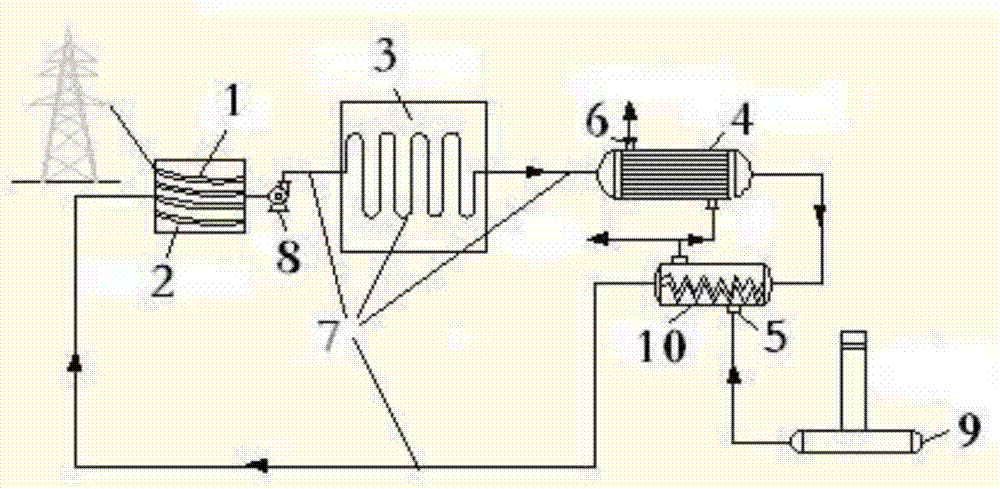

[0036] The valley electric steam boiler of this embodiment includes an electric heating device, an energy storage device, a steam output device and a heat transfer medium pipeline. The electric heating device is a heat transfer oil buffer tank 2 wrapped with an electric heat tracing 1 on the outside, and the inside is filled with heat transfer oil; The quartz sand composite molten salt described in is used as a heat storage material; the steam output device includes a preheater 10 and a steam generator 4, the preheater 10 includes a water inlet 5, and the steam generator 4 includes a steam outlet port 6; the heat transfer medium pipeline 7 communicates with the heat transfer oil buffer tank 2, the molten salt storage tank 3, the steam generator 4 and the preheater 10, and the heat transfer oil can pass through the circulating pump 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com