Spiral ventilation radiating brake drum

A brake drum and heat dissipation technology, applied in the direction of brake drums, slack adjusters, etc., can solve the problems of difficulty in increasing the braking force, temperature rise, and vehicle weight increase, so as to reduce production costs, prolong service life, and improve heat dissipation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

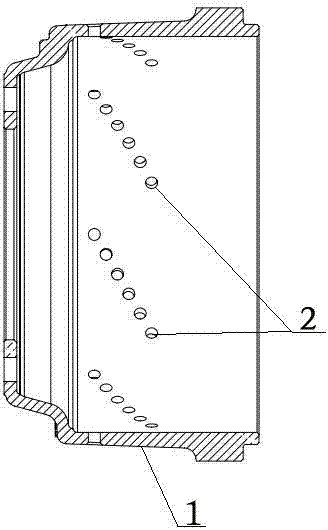

[0012] Such as figure 1 As shown, a spiral ventilation, heat dissipation type brake drum, which includes a brake drum, the middle part of the brake drum is a brake friction surface 1, and the brake friction surface 1 is provided with spiral uniformly distributed Cooling hole system 2, described cooling hole system 2 is 4 rows, and each row of cooling hole system 2 has 8 cooling holes, and every row of cooling hole system 2 is arranged in a straight line along the cross section of the brake drum. The heat dissipation holes of the heat dissipation hole system 2 are cast together with the brake drum, and the diameter of the heat dissipation holes is 8mm.

Embodiment 2

[0014] Such as figure 1 As shown, a spiral ventilation, heat dissipation type brake drum, which includes a brake drum, the middle part of the brake drum is a brake friction surface 1, and the brake friction surface 1 is provided with spiral uniformly distributed The heat dissipation hole system 2, the heat dissipation hole system 2 is 8 rows, and each row of the heat dissipation hole system 2 has 6 heat dissipation holes, and each row of the heat dissipation hole system 2 is arranged in a straight line along the cross section of the brake drum. The heat dissipation holes of the heat dissipation hole system 2 are cast together with the brake drum, and the diameter of the heat dissipation holes is 10mm.

Embodiment 3

[0016] Such as figure 1 As shown, a spiral ventilation, heat dissipation type brake drum, which includes a brake drum, the middle part of the brake drum is a brake friction surface 1, and the brake friction surface 1 is provided with spiral uniformly distributed The heat dissipation hole system 2, the heat dissipation hole system 2 is 10 rows, and each row of the heat dissipation hole system 2 has 4 heat dissipation holes, and each row of the heat dissipation hole system 2 is arranged in a straight line along the cross section of the brake drum. The heat dissipation holes of the heat dissipation hole system 2 are cast together with the brake drum, and the diameter of the heat dissipation holes is 15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com