Unrestraint assembly method of plug-in type bundled bracket

An assembly method and unconstrained technology, applied in the aerospace field, can solve problems such as limited operating space, low drilling efficiency, high hardness, etc., to achieve the effect of ensuring accurate reset and avoiding positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

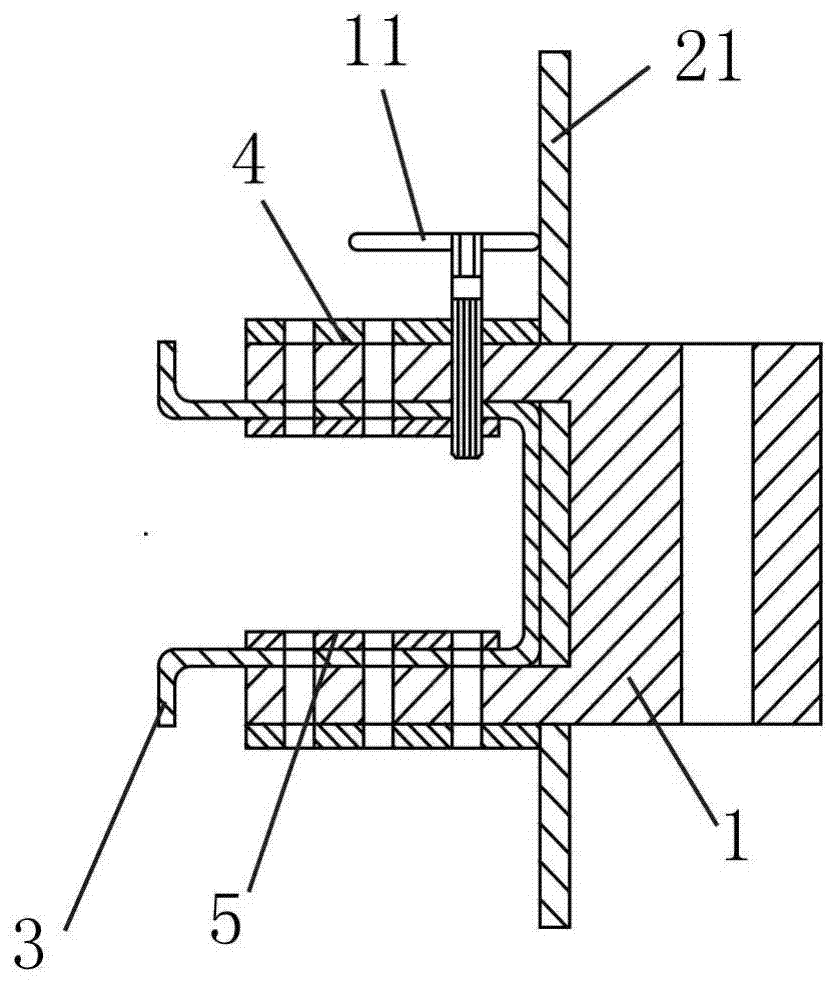

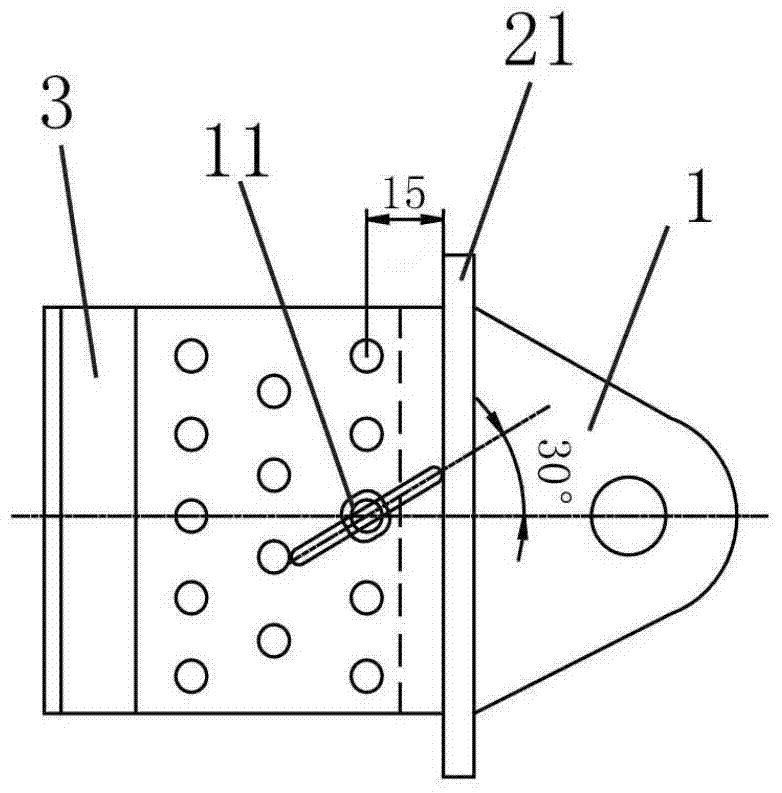

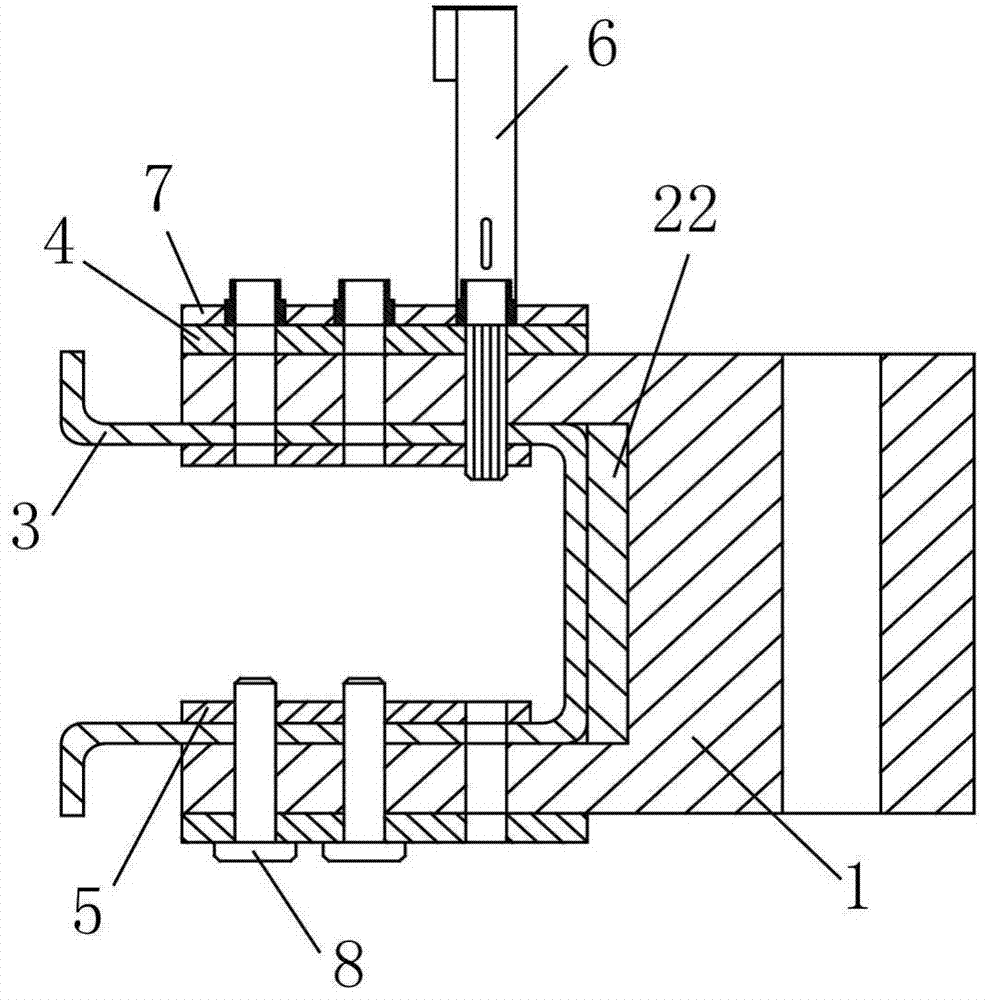

[0025] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The unconstrained assembly method of the plug-in binding support is to pre-assemble the composite interlayer composed of the binding support 1, the middle frame 2, and the inner and outer reinforcement plates (4, 5) - split-reset-split-reset, In this process, the process skin 22 is used to replace the skin 21, and on the basis of determining the positioning hole, the drill template 7 is introduced to complete the fine hinge positioning of the connection hole near the skin 21 side, and then the fine hinge position close to the skin 21 side is used. The connecting holes are used as the positioning reference to determine the positions of the remaining connecting holes, and finally the unconstrained plug-in assembly of the binding support 1 is completed.

[0027] In order to ensure the smooth assembly of the plug-in binding support and meet the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com