A processing method using electric discharge machining equipment

A technology of processing equipment and processing methods, applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of increased cost, cumbersome process, and prolonged production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

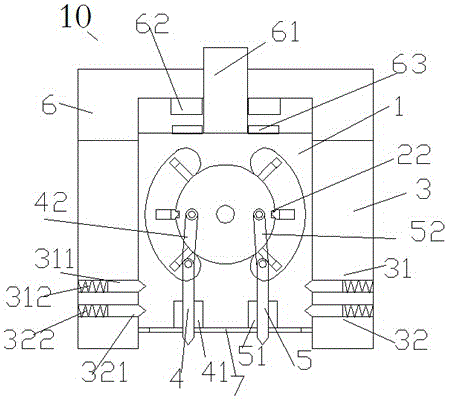

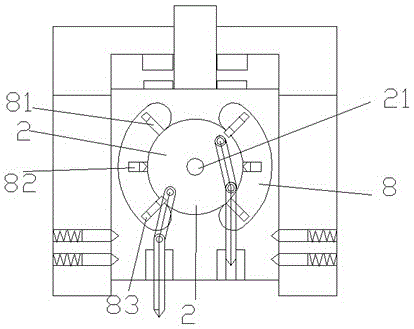

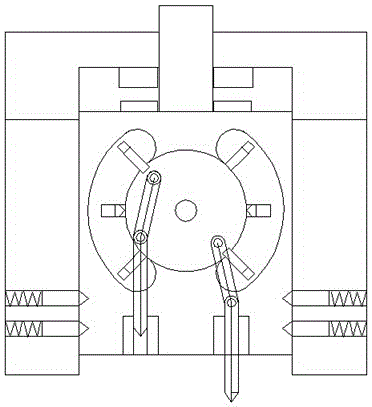

[0035] Refer below Figure 1-5 , To describe the present invention in detail.

[0036] A machining method using electric discharge machining equipment, the electric discharge machining equipment includes a main frame, an electric discharge machining head device 10, a front-rear direction moving motor 202, a front-rear direction moving block 200, and a left-right direction moving motor 201. The left and right directions are perpendicular to each other in the horizontal plane. The front and rear direction moving motor 202 is fixedly connected to the main frame and can drive the front and rear direction moving block 200 to move back and forth on the main frame. The left and right direction moving motor 201 is fixed to the front and rear moving block 200. Connected to drive the EDM head device 10 to move left and right on the moving block 200 in the forward and backward direction;

[0037] The EDM head device 10 includes a lower frame 3, an upper frame 6 and an inner frame 1. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com