A processing method for face-to-face modification of worm gear tooth surface

A processing method and tooth surface technology, which is applied to worm gears, components with teeth, belts/chains/gears, etc., can solve problems such as the inability to visually check the transmission of worm gears and worms, the difficulty of tooth surface modification, and troubles, etc. , to achieve the effect of easy control of the production process, high processing precision and simple processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

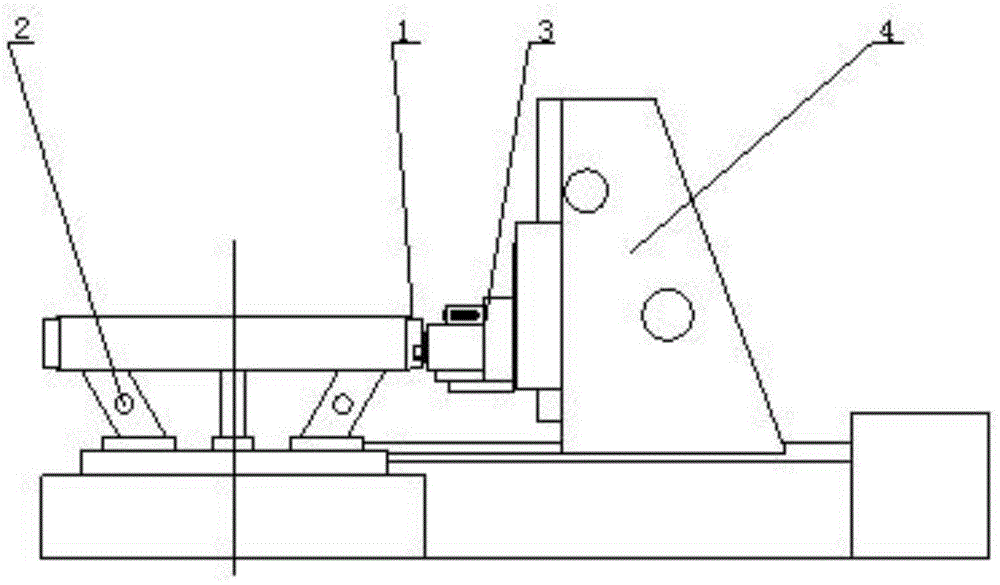

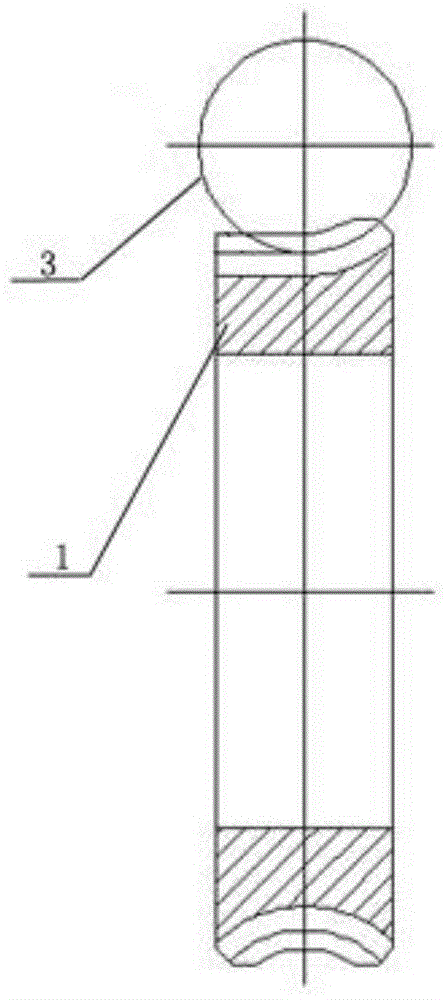

[0022] See figure 1 , is a schematic diagram of the processing state of the present invention, a method of face-to-face modification of the tooth surface of a worm gear according to the present invention, which is used to mill the tooth surface of the 1 / 2 tooth width of the worm gear flat according to the height of the pitch circle, including the following steps

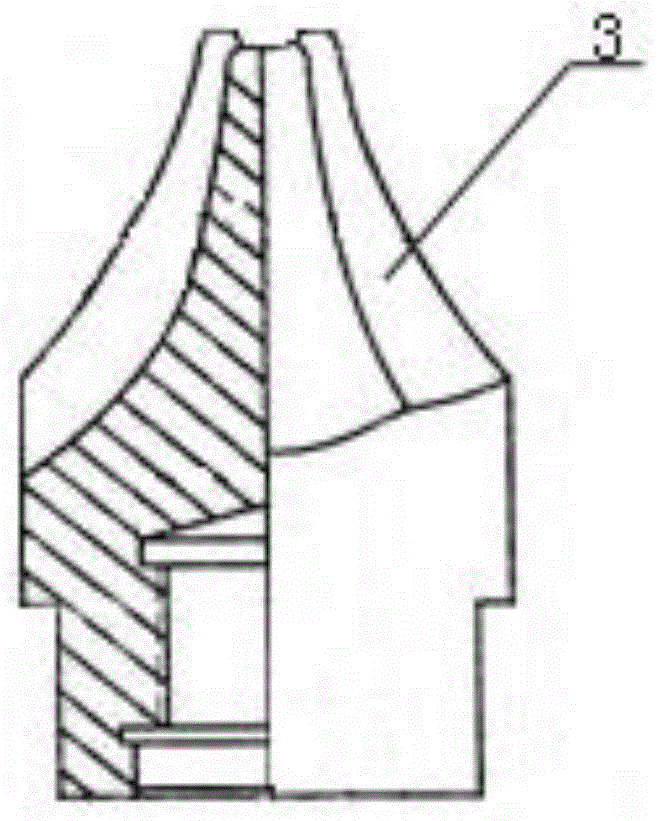

[0023] 1) Process the finger-shaped milling cutter 3 according to the tooth shape at the index circle of the worm wheel after tooth milling, the material of the milling cutter 3 is W18Cr4V, and install the milling cutter 3 on the gear hobbing machine 4;

[0024] 2) Put the milled worm gear workpiece 1 flat on the working table of the gear hobbing machine 4, support it with 8 contour pad irons 2, take the outer circle and end face of the worm gear workpiece 1 as the positioning reference,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com