Insulated wire stripping device

A technology of insulated wires and wires, which is applied in the direction of overhead line/cable equipment, dismantling/armored cable equipment, etc., can solve the problem that the insulated wire stripping device cannot be operated live, and achieves simple structure, low manufacturing cost, and improved satisfaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

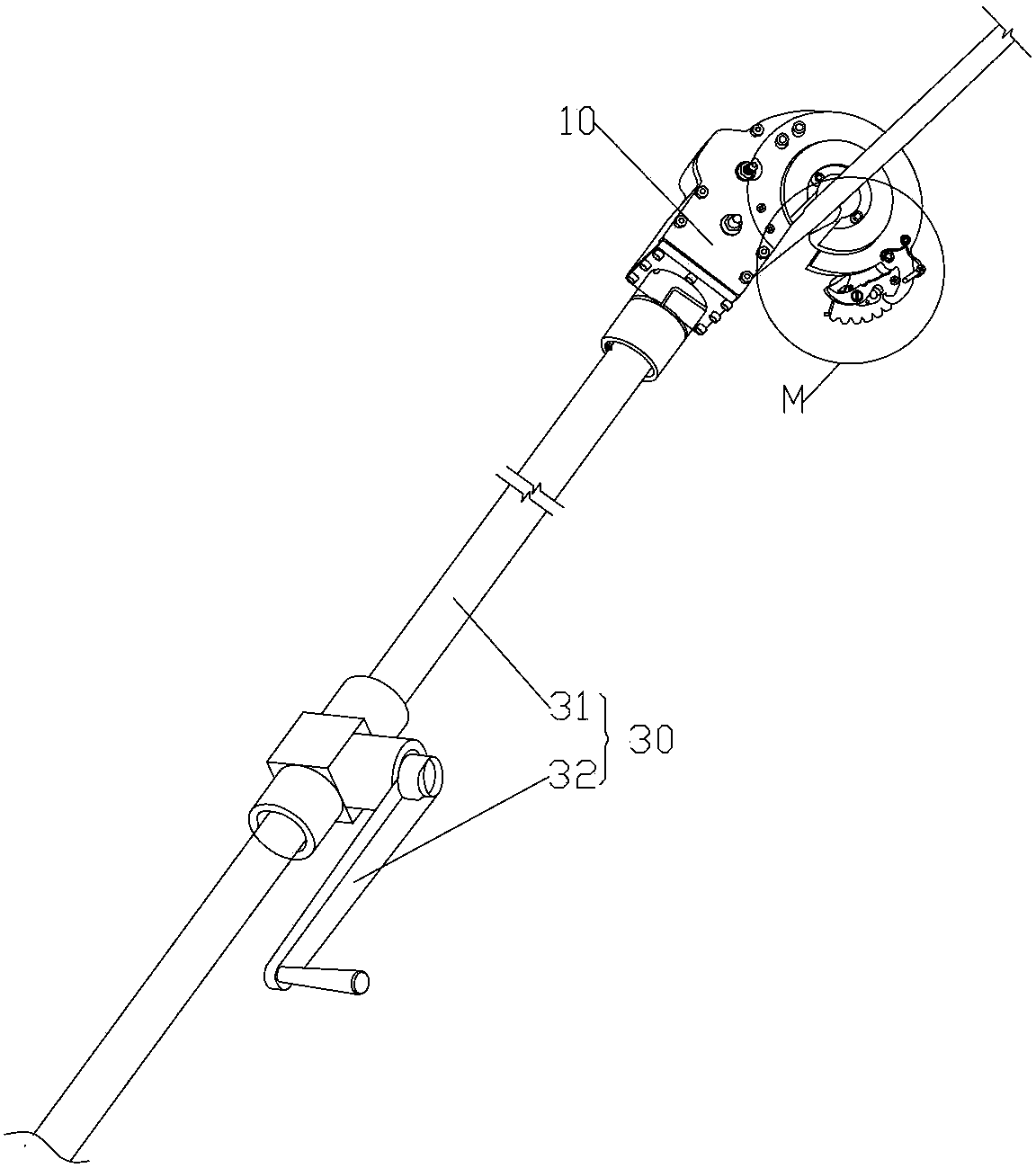

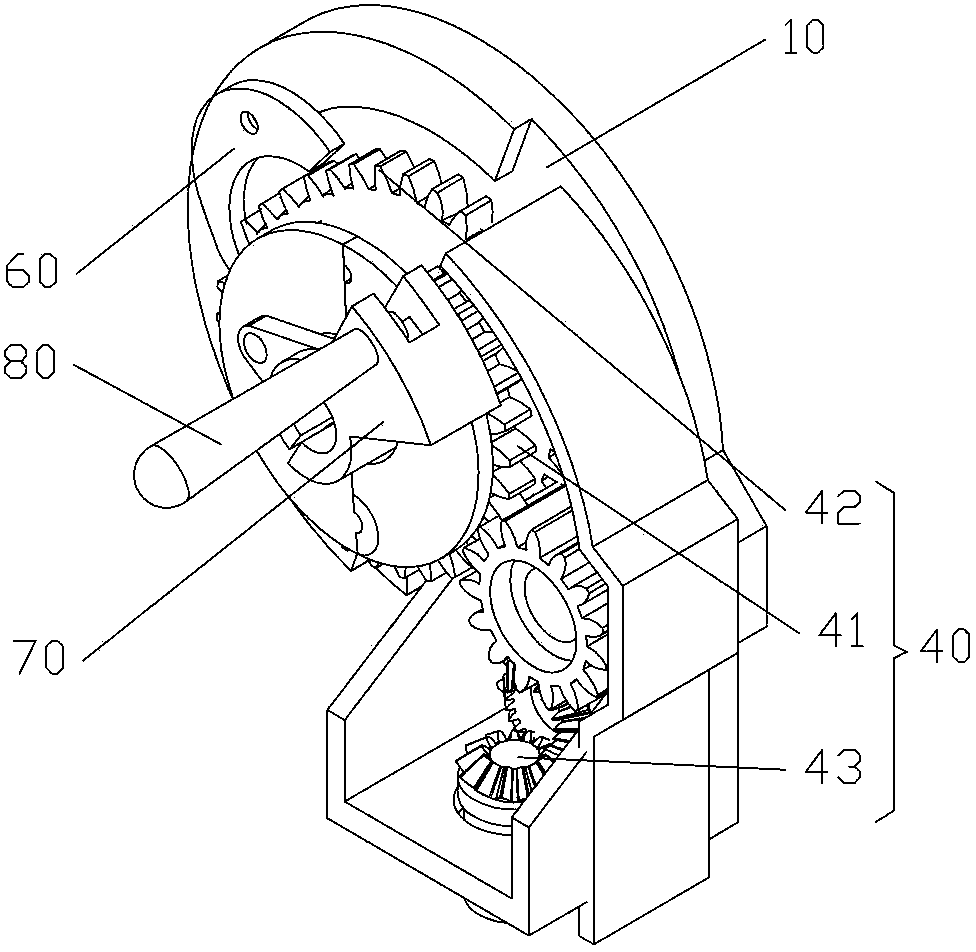

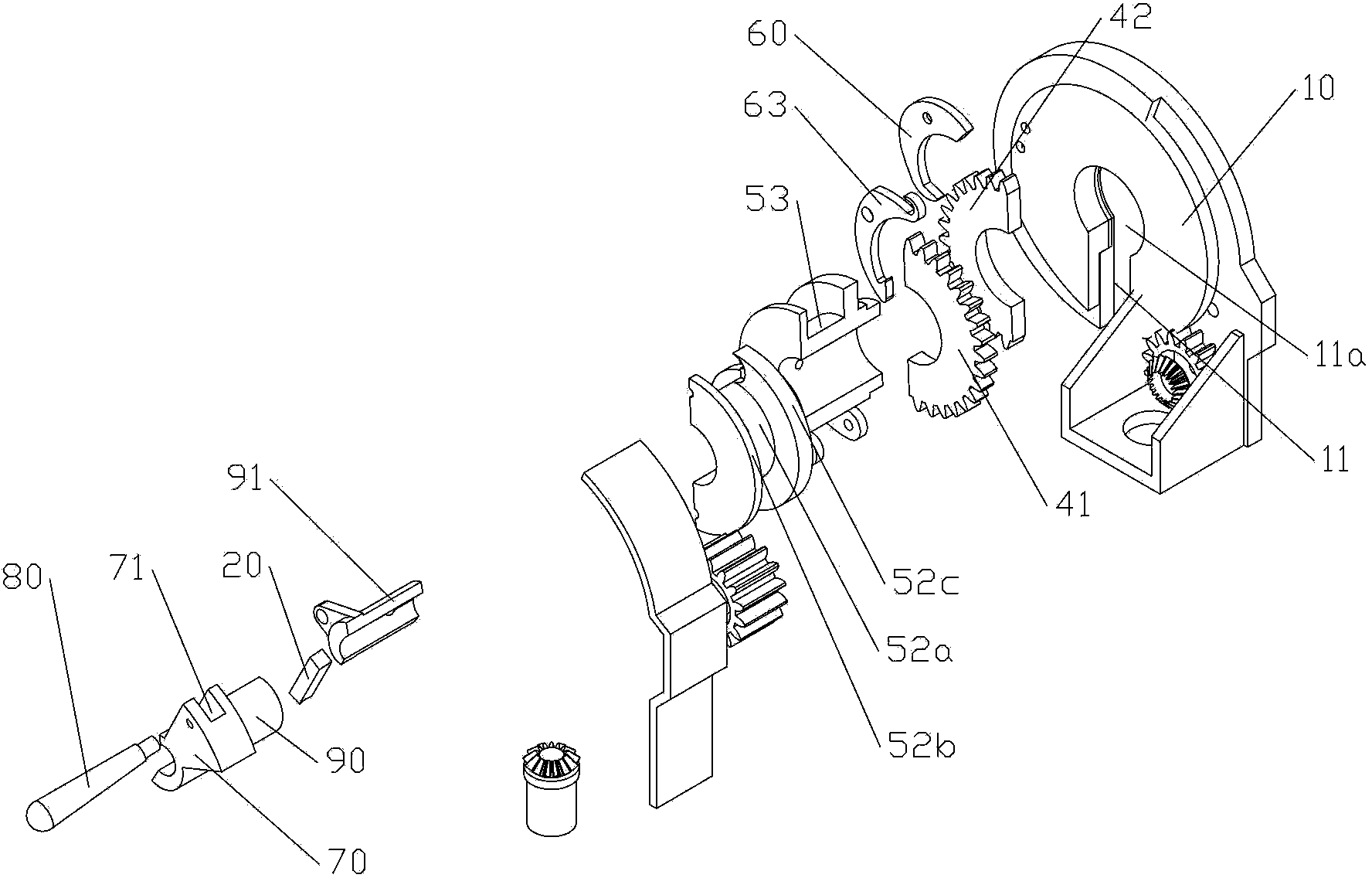

[0032] The invention provides an insulated wire stripping device. Such as Figures 1 to 9 As shown, the insulated wire stripping device includes: a base 10, the base 10 includes a first opening 11 for wires to pass through, and one end of the first opening 11 is formed with a first wire receiving hole 11a; a cutting unit, the cutting unit includes a winding The axis of the first wire receiving hole 11a rotates the cutter 20, the cutter 20 is pivotally connected to the base 10; the insulating rod operating assembly 30, the first end of the insulating rod operating assembly 30 is connected to the base 10, and The first end of the insulating rod operating assembly 30 has a driving part for driving the cutter 20 .

[0033] When using the insulated wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com