Corrugated expansion joint

A bellows and compensator technology, which is applied to expansion compensation devices, pipe components, pipes/pipe joints/fittings for pipelines, etc., can solve problems such as large internal stress, failure of bellows seals, and large thickness differences. Achieve the effect of prolonging service life, ensuring sealing effect and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

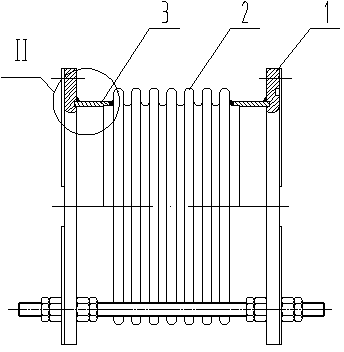

[0016] The bellows compensator shown in the accompanying drawings includes flange 1 and bellows 2; flange 1 and bellows 2 are connected through connecting pipe 3; connecting pipe 3 is connected to the end face of flange 1 in a sealed connection; in this embodiment, flange 1 The end face is provided with a groove, and the connecting pipe 3 is embedded in the groove.

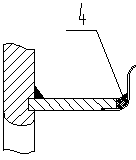

[0017] There is a spigot in the connecting port hole between the connecting pipe 3 and the bellows 2, and the bellows 2 is sealed in the spigot; the axial gap between the end of the connecting pipe 3 and the bellows 2 is filled with silica gel 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com