Gypsum whisker dry method transformation method

A gypsum whisker and transformation technology, applied in the field of gypsum whisker dry transformation technology, can solve the problems of uneven crystal shape, low production efficiency, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

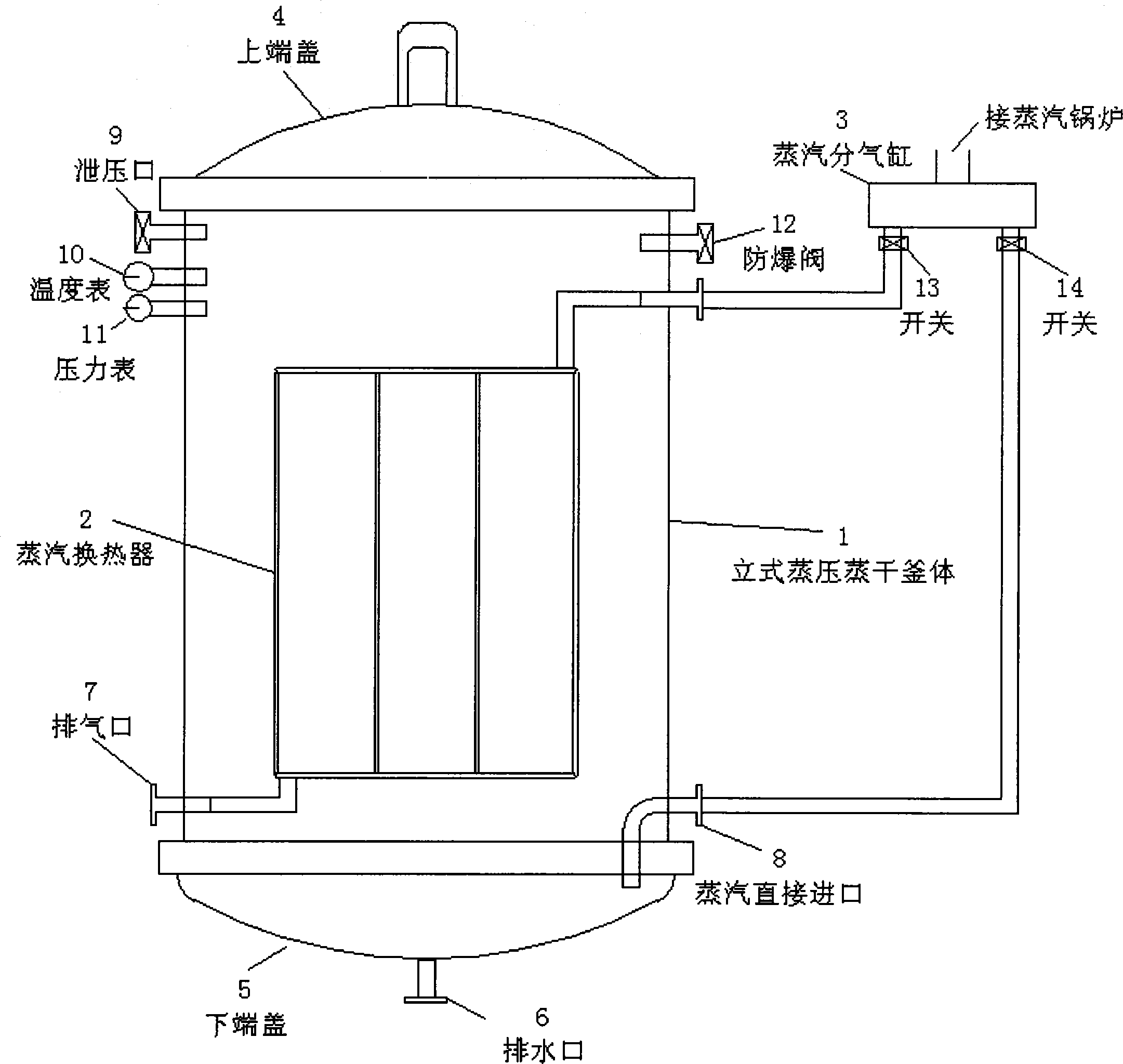

[0010] As shown in the figure, the lower end cover 5 of the autoclaved drying kettle 1 is sealed, and the gypsum whiskers are packed into the autoclaved drying kettle 1, preferably without the steam heat exchanger 2;

[0011] Seal the upper end cover 4 of the autoclaved steaming kettle 1, close the pressure relief port 9 on the kettle body and the drain port 6 of the lower end cover, and slightly open the exhaust port 7;

[0012] Simultaneously open the switch 13 and the switch 14 leading to the steam heat exchanger and the direct steam inlet on the steam sub-cylinder 3, and feed in steam at 130°C;

[0013] When the temperature displayed by the thermometer 10 in the autoclave 1 reaches 60° C., turn off the switch 14;

[0014] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 120°C and the pressure displayed by the pressure gauge 11 reaches 0.2MPa-0.5MPa, the switch 13 is turned off;

[0015] After heat preservation and pressure holding for ...

Embodiment 2

[0019] As shown in the figure, the lower end cover 5 of the autoclave 1 is sealed, and the gypsum whiskers are put into the autoclave 1, preferably to cover the steam heat exchanger 2;

[0020] Seal the upper end cover 4 of the autoclaved steaming kettle 1, close the pressure relief port 9 on the kettle body and the drain port 6 of the lower end cover, and slightly open the exhaust port 7;

[0021] Simultaneously open the switch 13 and the switch 14 leading to the steam heat exchanger and the direct steam inlet on the steam sub-cylinder 3, and feed steam at 150°C;

[0022] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 80°C-90°C, turn off the switch 14;

[0023] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 120°C-150°C, and the pressure displayed by the pressure gauge 11 reaches 0.2MPa-0.3MPa, the switch 13 is turned off;

[0024] After heat preservation and pressure holding for 3-6 hours, open the...

Embodiment 3

[0028] As shown in the figure, the lower end cover 5 of the autoclave 1 is sealed, and the gypsum whiskers are packed into the autoclave 1, preferably without the steam heat exchanger 2;

[0029] Seal the upper end cover 4 of the autoclaved steaming kettle 1, close the pressure relief port 9 on the kettle body and the drain port 6 of the lower end cover, and slightly open the exhaust port 7;

[0030] Simultaneously open the switch 13 and the switch 14 leading to the steam heat exchanger and the direct steam inlet on the steam sub-cylinder 3, and feed in steam at 190°C;

[0031] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 100° C., turn off the switch 14;

[0032] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 150°C and the pressure displayed by the pressure gauge 11 reaches 0.3MPa-0.5MPa, the switch 13 is turned off;

[0033] After heat preservation and pressure holding for 3-6 hours, open the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com