A polymer material pen core and pencil

A technology of polymer materials and refills, applied in the field of stationery, can solve the problems of blurred handwriting, colorants sticking to the body, and handwriting being easily rubbed and blurred.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

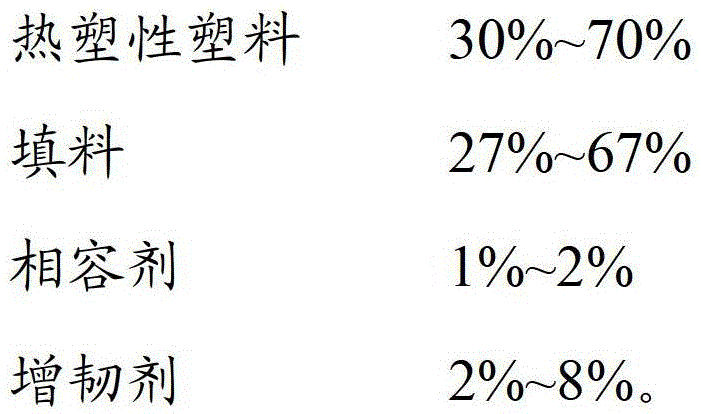

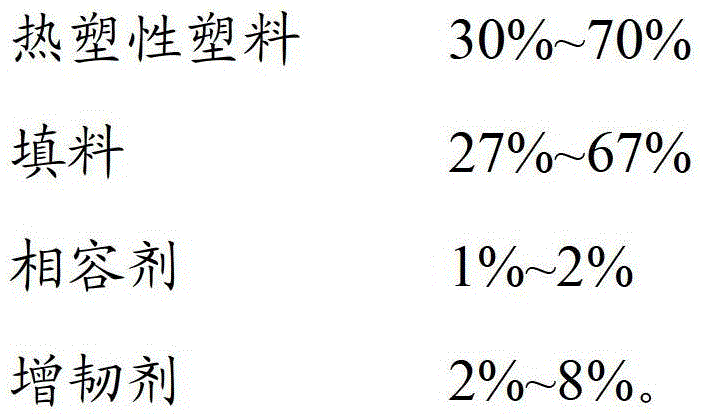

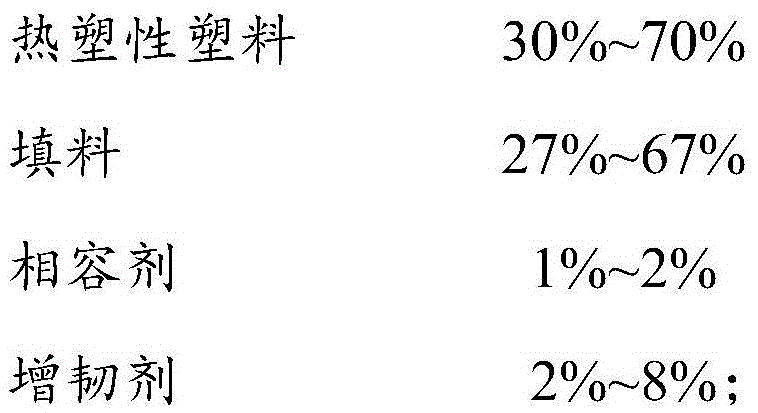

[0022] A polymer material pen core, including the following raw material components in weight percentage: 30% of PFA, 60% of filler, 2% of compatibilizer, and 8% of toughening agent.

[0023] The chromaticity of the refill thus made can reach the writing effect that HB pencils can achieve, the Knoop hardness can reach the hardness that H-type pencils can achieve, and can be bent and has good toughness. Rub it with your hands without sticking any fillers and keep your hands clean.

Embodiment 2

[0025] A polymer material pen core, comprising the following raw material components in weight percentage: 70% of nylon, 27% of filler, 1% of compatibilizer, and 2% of toughening agent.

[0026] The chromaticity of the refill thus made can reach the writing effect that a class F pencil can achieve, and the Knoop hardness can reach the hardness that a 2H pencil can achieve, and it can be bent and has good toughness. Rub it with your hands without sticking any fillers and keep your hands clean.

Embodiment 3

[0028] A polymer material pen core, including the following raw material components in weight percentage: POM 30%, filler 67%, compatibilizer 1%, toughening agent 2%.

[0029] The color of the pen core thus made can reach the writing effect that the H-type pencil can achieve, the Knoop hardness is the hardness that the H-type pencil can achieve, and it can be bent and has good toughness. Rub it with your hands without sticking any fillers and keep your hands clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com