Method for controlling gap between upper framework and lower framework of continuous casting hydraulic fan-shaped section

A control method and segment technology, which is applied in the field of gap control between the upper and lower frames of the continuous casting hydraulic segment, can solve problems such as effect differences, achieve the effects of increasing service life, improving casting machine operation rate, and ensuring the quality of casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

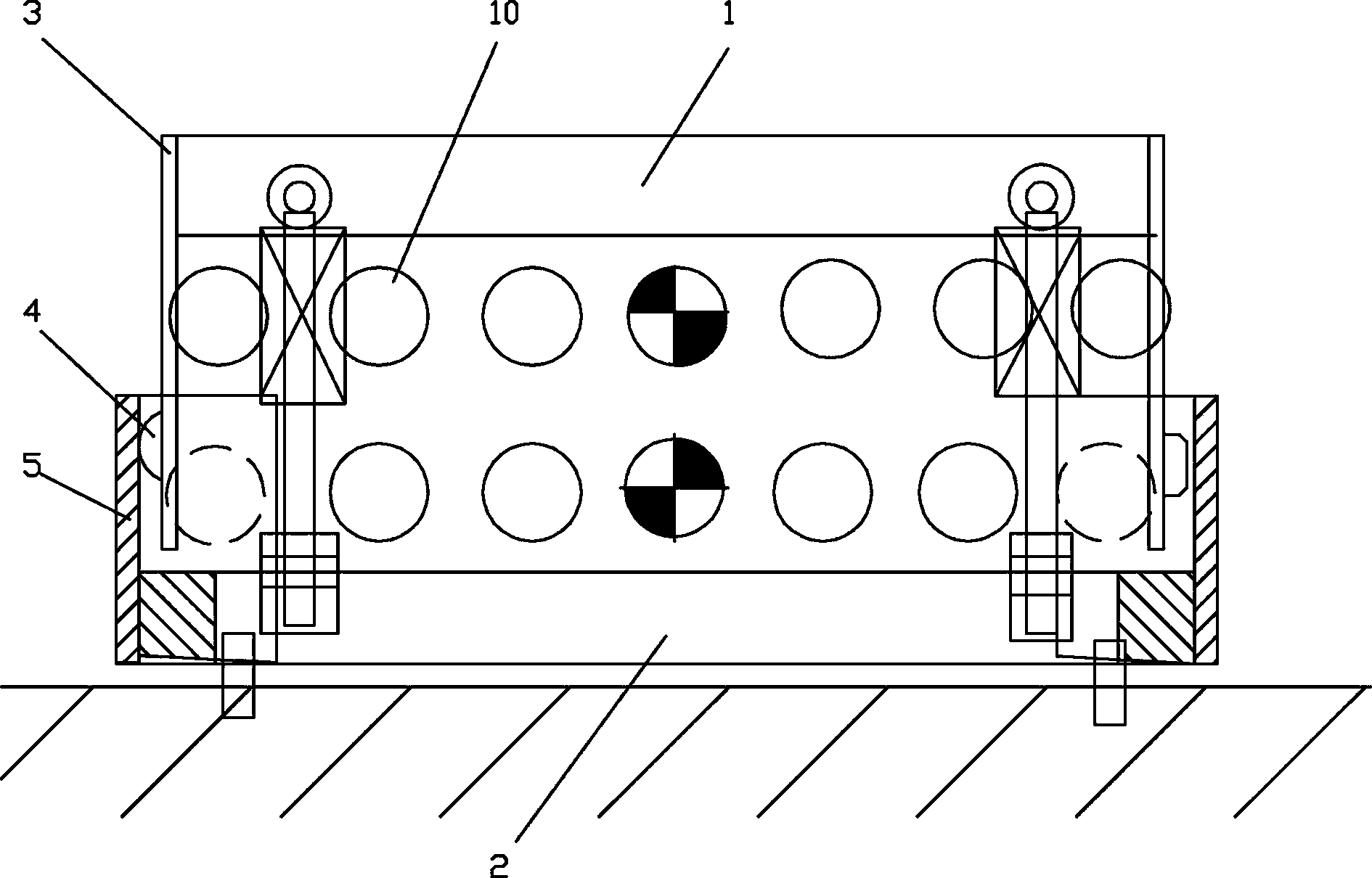

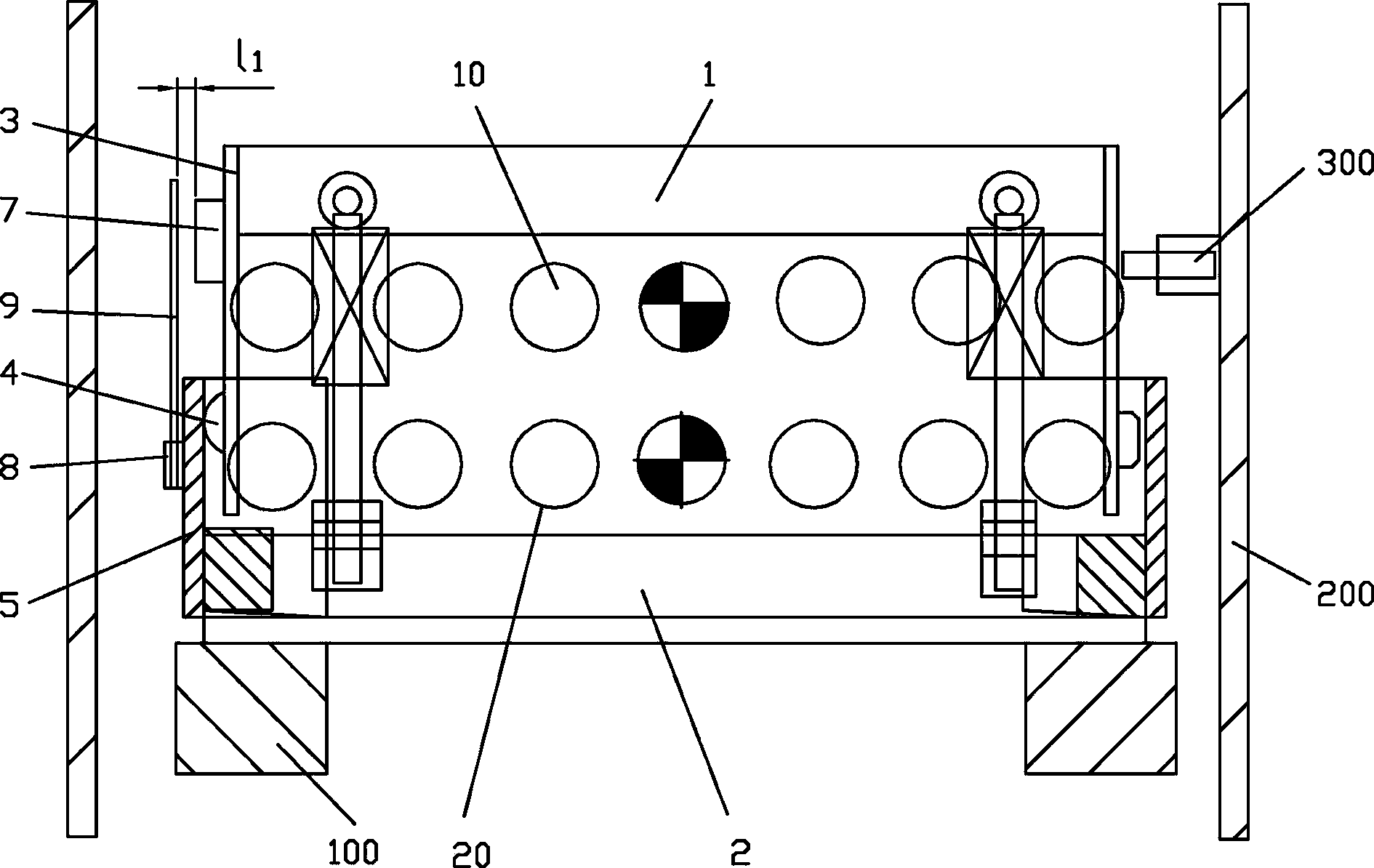

[0022] see Figure 1 to Figure 7 , a method for controlling the gap between the upper and lower frames of a continuous casting hydraulic segment according to the present invention, the front and rear sides of the upper frame of the hydraulic segment corresponding to the front and rear sides of the lower frame 2 are provided with guide mounting plates 3 and guide blocks connected thereto by fixing bolts 4. Take the upper and lower frames of the fan-shaped section off-line and place them on the standard maintenance platform 100. The maintenance frames 200 are set on both sides of the standard maintenance platform 100, and the upper part of the maintenance frame 200 corresponding to the entrance side of the fan-shaped section is provided with a jack that can lift the upper frame 1. 300; open the jack 300, and gradually lift the upper frame 1 toward the outlet of the fan-shaped section. When the upper roller system 10 of the upper frame 1 of the fan-shaped section is aligned with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com