Plastic honey extractor

A honey shaker and plastic technology, applied in the field of honey harvesting tools, can solve the problem of high cost of honey shaker, achieve the effect of eliminating heavy metal pollution, unique measures, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with accompanying drawing, the present invention is described in detail:

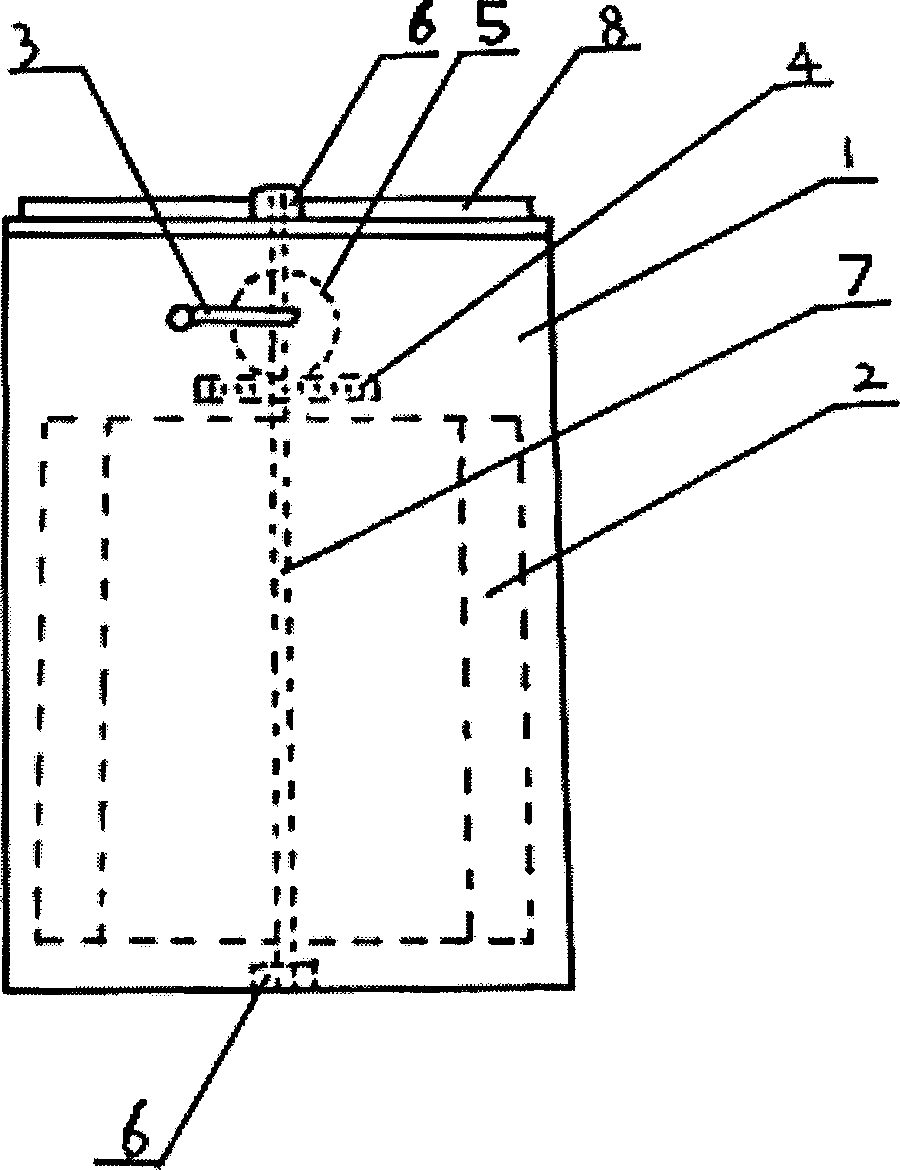

[0023] The present invention is that this machine is bucket body (1), honey tank placement frame (2), handle (3), gear one (4), gear two (5), bearing (6), rotating shaft one (7), fixed Frame (8) is formed.

[0024] figure 1 , figure 2 , image 3 with Figure 4 All shown are structural representations of the present invention. Among them, 1 is the barrel (1), 2 is the housing frame of the honey tank (2), 3 is the handle (3), 4 is the first gear (4), 5 is the second gear (5), 6 is the bearing (6), 7 is rotating shaft one (7), and 8 is fixed mount (8), and 9 is rotating shaft two (9), and 10 is the fixed rod (10) of gear two.

[0025] The honeycomb placement frame (2) and the gear (4) are placed in the rotating shaft one (7), one of the two bearings (6) is placed on the fixed frame (8), and the other is placed on the bottom of the barrel (1). Rotating shaft one (7) is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com