Pure flow trigger regenerative type valve control structure

A valve control, regenerative technology, applied in valve details, valve devices, engine components, etc., can solve problems such as gear slippage and wear gears, and achieve the effect of avoiding wear and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

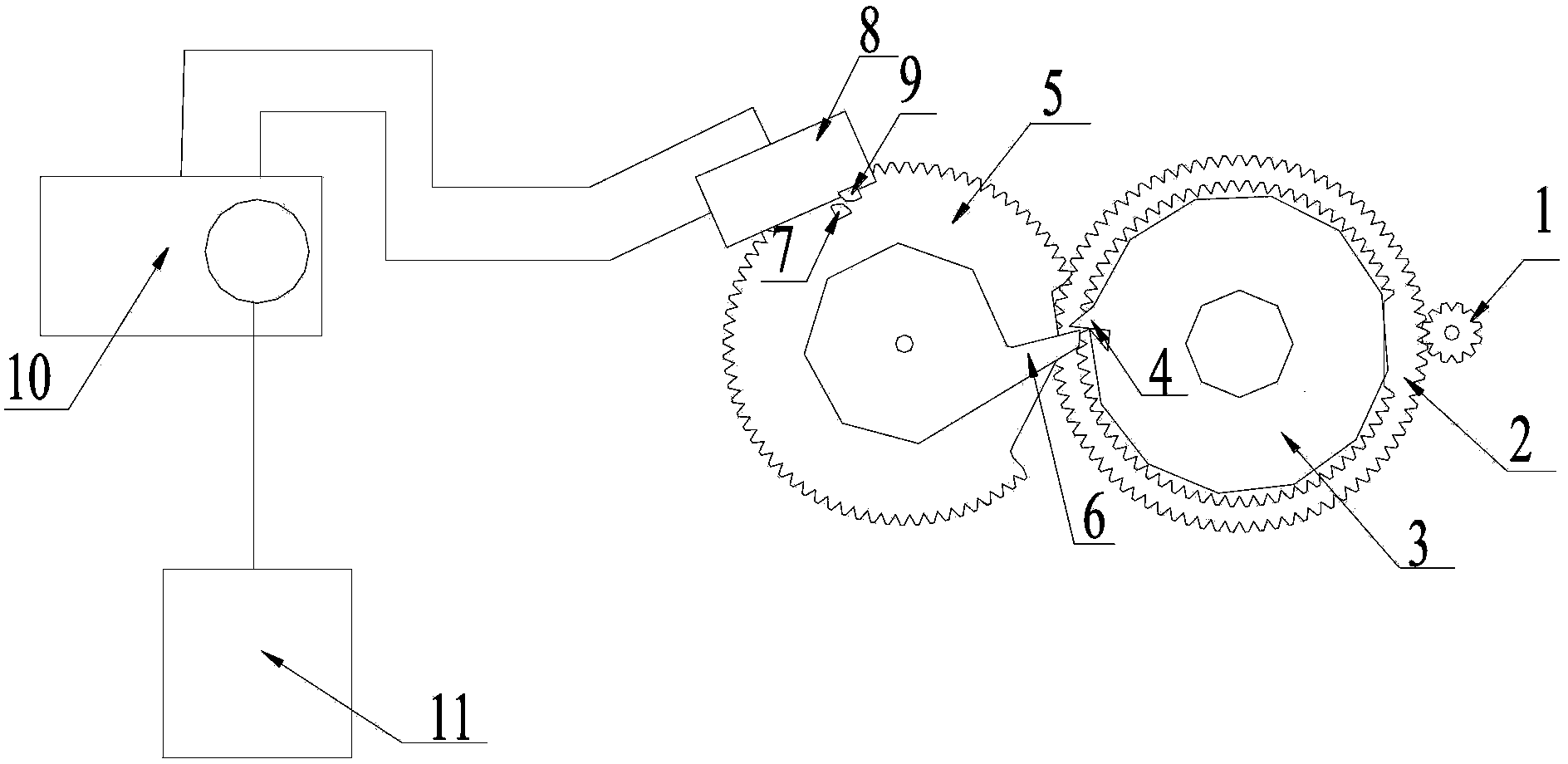

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] A pure flow trigger regenerative valve control structure, including a pinion gear 1 driven by a flow meter and a flow gear, the flow gear includes a meshing gear 2 and a paddle gear 3, the meshing gear 2 and the paddle gear 3 are coaxially fixed, the pinion gear 1 is meshed with the meshing gear; the paddle gear 3 is provided with a paddle 4 protruding from the circumference of the paddle gear 3; the paddle gear 3 is meshed with the regenerative gear 5, so The regenerating gear 5 is provided with a trigger piece 6 protruding from the circumference of the regenerating gear 5, a boss 7 is arranged on the peripheral end surface of the regenerating gear 5, and a micro switch 8 is arranged above the boss 7, The switch plate 9 of the micro switch 8 is located in front of the circular motion track of the boss 7, the micro switch 8 is connected to a motor 10, the micro ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com