Switch valve

A switching valve, valve body technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as screw off, poor quality of switching valve, uneven piston, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

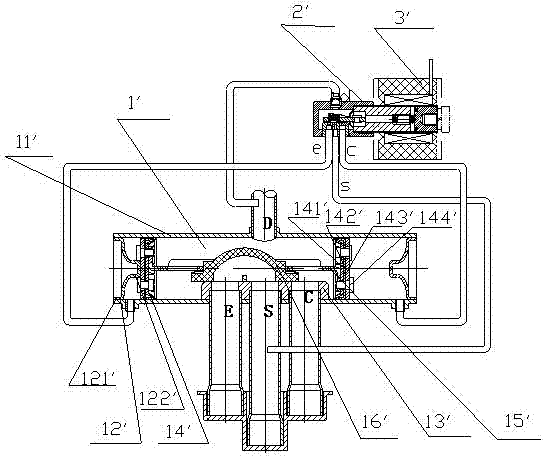

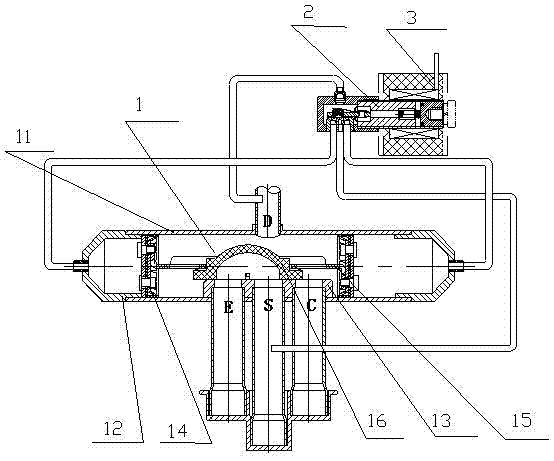

[0022] Such as figure 2 , 3 As shown, the switching valve includes the main valve 1, the pilot valve 2 and the coil 3. The electromagnetic force of the coil 3 acts on the pilot valve 2 to control the main valve 1 to realize the switching between cooling and heating of the air conditioner. The main valve 1 includes a hollow cylinder Shaped valve body 11, which blocks the end caps 12 at both ends of the valve body 11. The inner cavity of the valve body 11 is provided with a valve seat 13, two pistons 14 respectively placed on both sides of the valve seat 13, and two pistons connected to each other. The connecting rod 15 of 14 is fixedly arranged on the slider 16 in the middle of the connecting rod 15. The end cover 12 is in the shape of a hat, and the axis is successively provided with a cap top 121, a middle part 122 and a contact part 123. The cap top 121 or The middle part 122 is provided with a capillary hole 126 for installing a capillary. The main valve 1 and the pilot v...

no. 2 approach

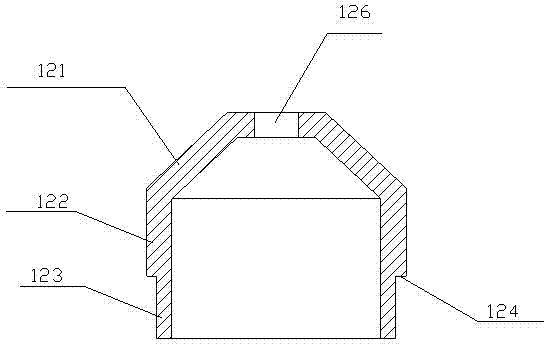

[0027] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the outer diameters of the middle part 122 and the contact part 123 of the end cap 12 are equal, and the outer peripheral surface of the connection between the middle part 122 and the contact part 123 is provided with a convex ring 125, and the convex ring The outer diameter of 125 is greater than the outer diameter of the contact portion 123, so a step 124 is formed between the protruding ring 125 and the contact portion 123. The outer diameter of the protruding ring 125 is equal to the height of the outer peripheral surface of the valve body 11, forming a relatively smooth surface. The inner peripheral surfaces are in contact.

[0028] In this embodiment, the end cover 12 utilizes the protruding ring 125 on the outer peripheral surface at the junction of the middle part 122 and the contact part 123. When assembling, the contact part 123 of the end cover 12 is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com