Manual bobbin tape splicing machine

A technology of bonding machine and round belt, applied in mechanical equipment, connecting components, etc., can solve the problems of slow processing speed, complex production equipment, weak bonding of round belt, etc., and achieve the effect of fast production speed and simple production operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

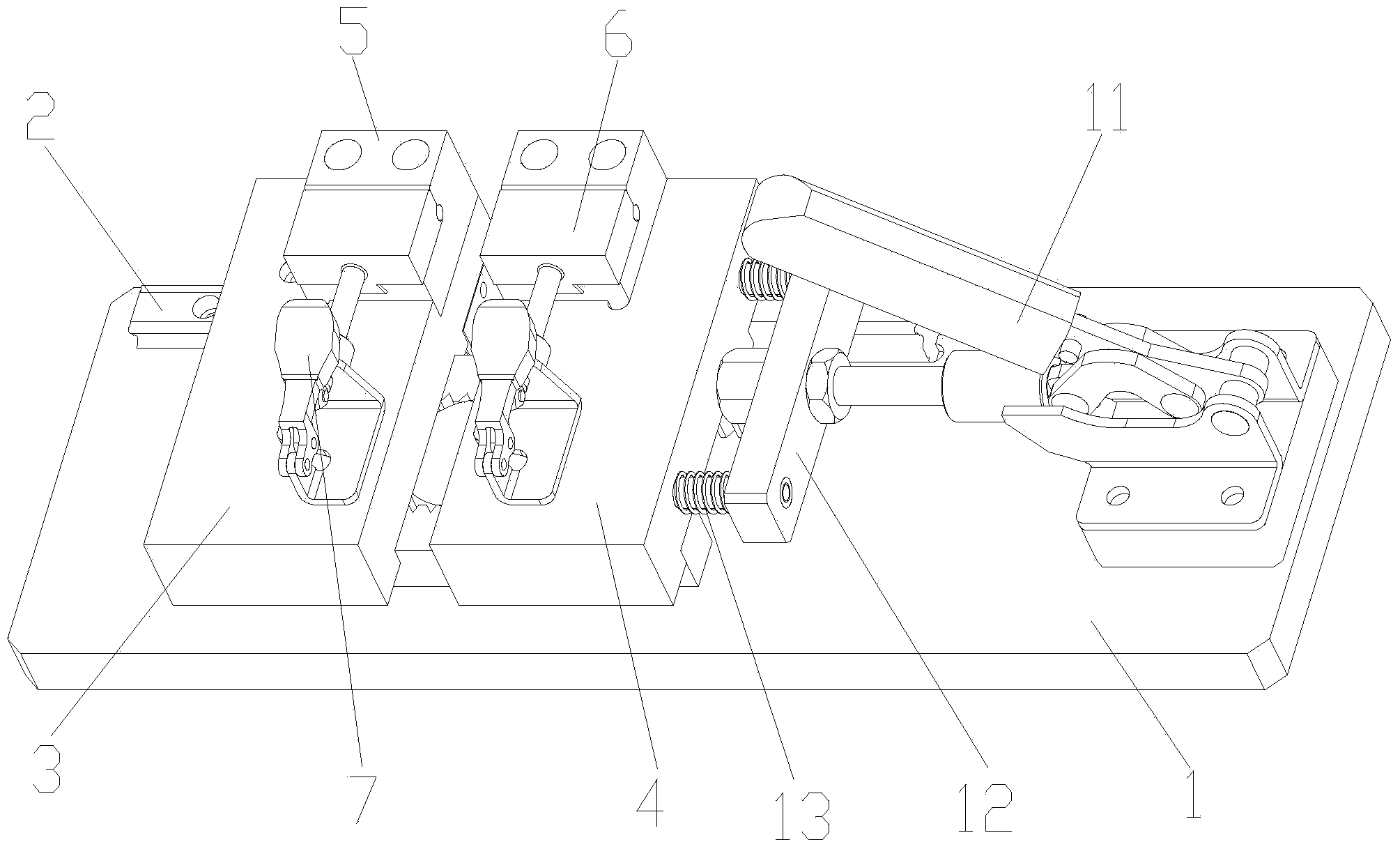

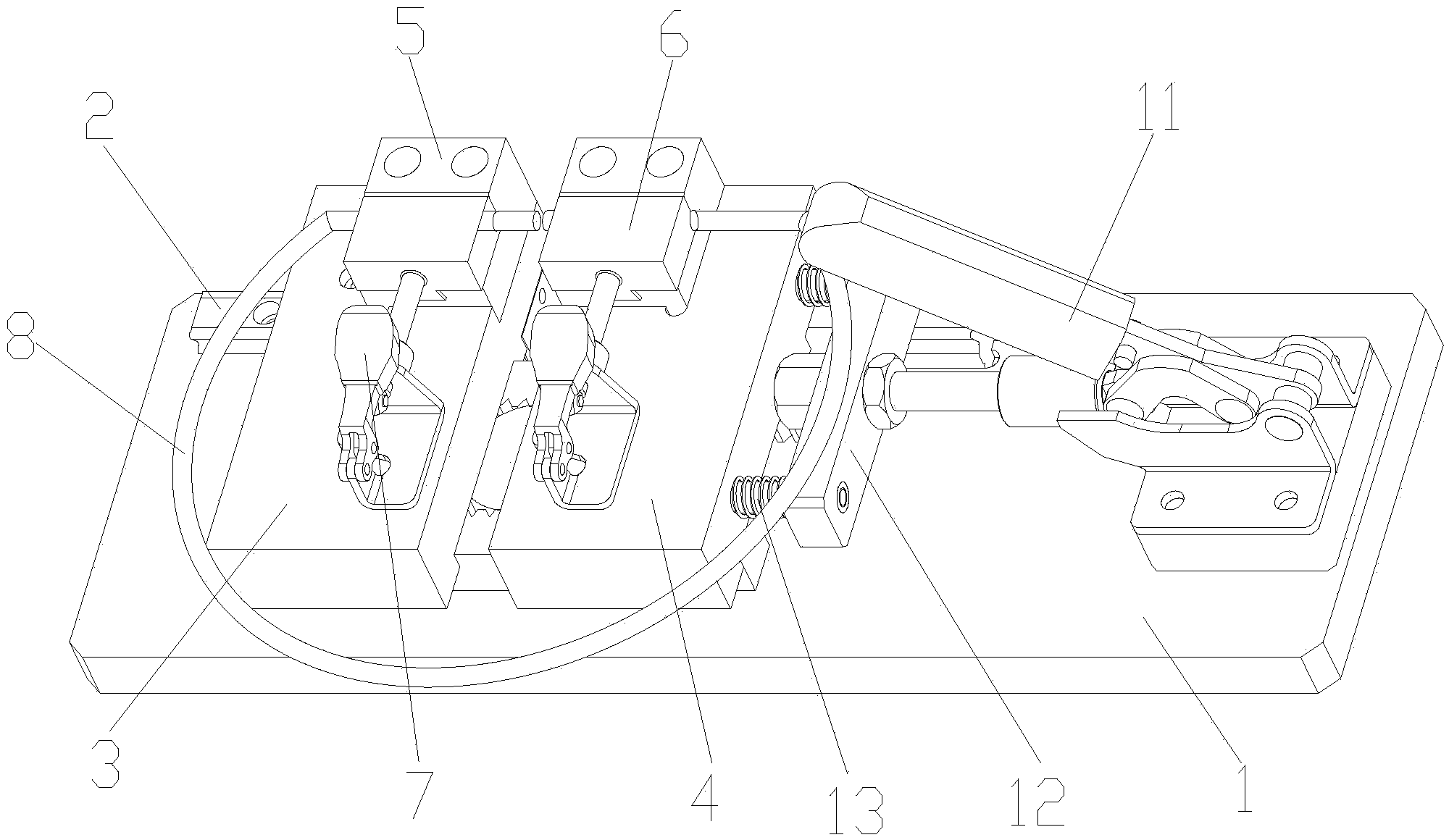

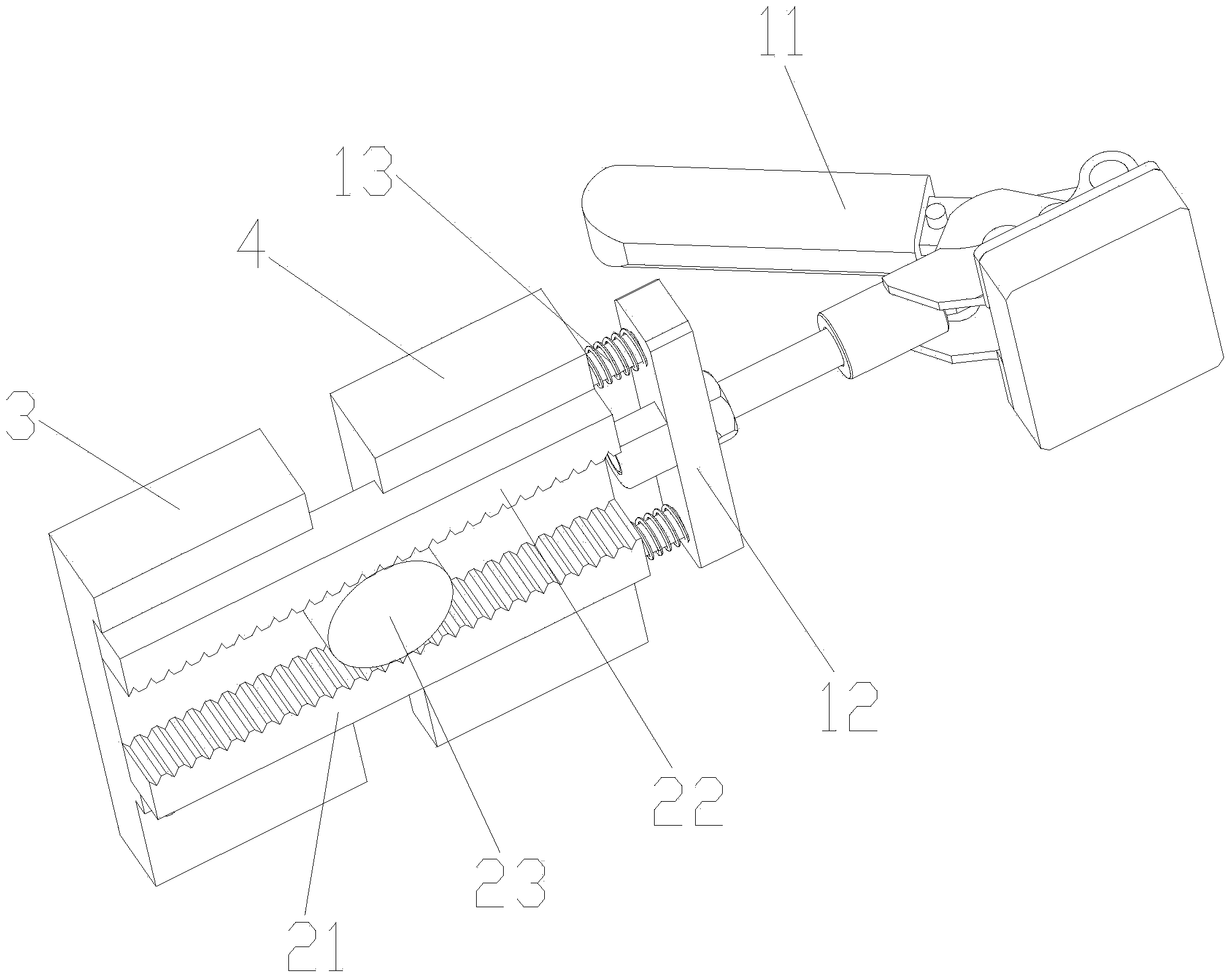

[0016] as attached Figure 1-3 The shown manual round belt bonding machine of the present invention includes a bottom plate 1, a moving guide rail 2, a left sliding block 3, a right sliding block 4, a clamping and fixing block 5, a clamping and positioning block 6, a first manual Chuck 7, pressing mechanism and transmission mechanism; Described base plate 1 is provided with moving guide rail 2; Described moving guide rail 2 is provided with the left slide block 3 and the right slide block 4 of relative sliding; Described left slide block 3 and The right sliding block 4 is respectively provided with a clamping and fixing block 5; the longitudinal side of the clamping and fixing block 5 is provided with a first manual chuck 7; the pressure bar of the first manual chuck 7 is provided with a clamping positioning Block 6; the clamping and fixing block 5 and the clamping and positioning bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com