Air cleaner of mini-tiller handle-type double-filtration gasoline (diesel) engine

An air filter and double filtration technology, applied in the direction of machine/engine, combustion air/combustion-air treatment, mechanical equipment, etc., can solve the problems of high maintenance rate, short size, increase user production cost, etc., to achieve air dust The effect of low content, improved service life and reasonable structure design

Inactive Publication Date: 2014-12-24

史大修

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

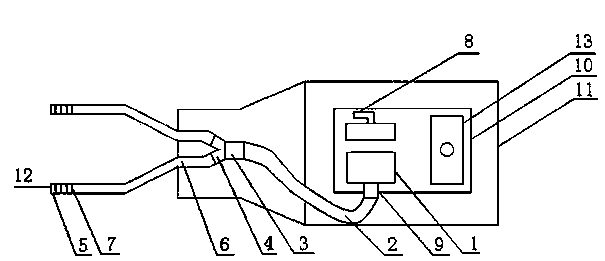

Existing tiller volume is short and small, mainly comprises the engine 10 that is installed on the fuselage 11, is installed near the engine 10 and is used to filter the air filter 1 that enters the air in the engine 10, exhaust pipe 8, oil tank 13, and machine Body 11 is connected with the armrest metal conduit 6, and the bottom of the engine 10 is provided with a tiller wheel and a tiller knife. The engine 10 and the air filter 1 are too close to the tiller knife and the ground, and the dust is flying during work, and the surrounding air environment is quite Bad, the air filter 1 is very easy to block, if the air entering the engine 10 is too dusty, the damage to the engine 10 is quite serious, resulting in a high maintenance rate and increasing the production cost of the user

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an air cleaner of a mini-tiller handle-type double-filtration gasoline (diesel) engine and belongs to the technical field of structures of air cleaners. The air cleaner comprises an air filter (1), an air guide tube (2) is arranged at the position of an air inlet of the air filter (1), the other end of the air guide tube (2) is divided into two branch tubes (4) through a tee joint (3), and the two branch tubes (4) are communicated with two armrest metal guide tubes (6) of a mini-tiller respectively. The air cleaner of the mini-tiller handle-type double-filtration gasoline (diesel) engine has the advantages that the structural design is reasonable, the blocking is not prone to occur, costs are low, and the usage is convenient.

Description

technical field [0001] The invention relates to a handle-type double-filter air filter for steam (diesel) and oil engines of a tiller, belonging to the technical field of air filter structures. Background technique Existing tiller volume is short and small, mainly comprises the engine 10 that is installed on the fuselage 11, is installed near the engine 10 and is used to filter the air filter 1 that enters the air in the engine 10, exhaust pipe 8, oil tank 13, and machine Body 11 is connected with the armrest metal conduit 6, and the bottom of the engine 10 is provided with a tiller wheel and a tiller knife. The engine 10 and the air filter 1 are too close to the tiller knife and the ground, and the dust is flying during work, and the surrounding air environment is quite Bad, the air filter 1 is very easy to block, if the air dust entering the engine 10 is too much, the damage to the engine 10 is quite serious, resulting in a high maintenance rate and increasing the produc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02M35/024

Inventor 史大修

Owner 史大修

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com