Automobile door handle fixing structure

A technology for fixing structures and door handles, which can be applied to vehicle locks, building structures, and lock applications. It can solve problems such as insufficient strength of plastic buckles, falling off of door handle bases, and wear and tear of threaded teeth, and achieve good strength and convenience. The effect of repeated disassembly and assembly and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

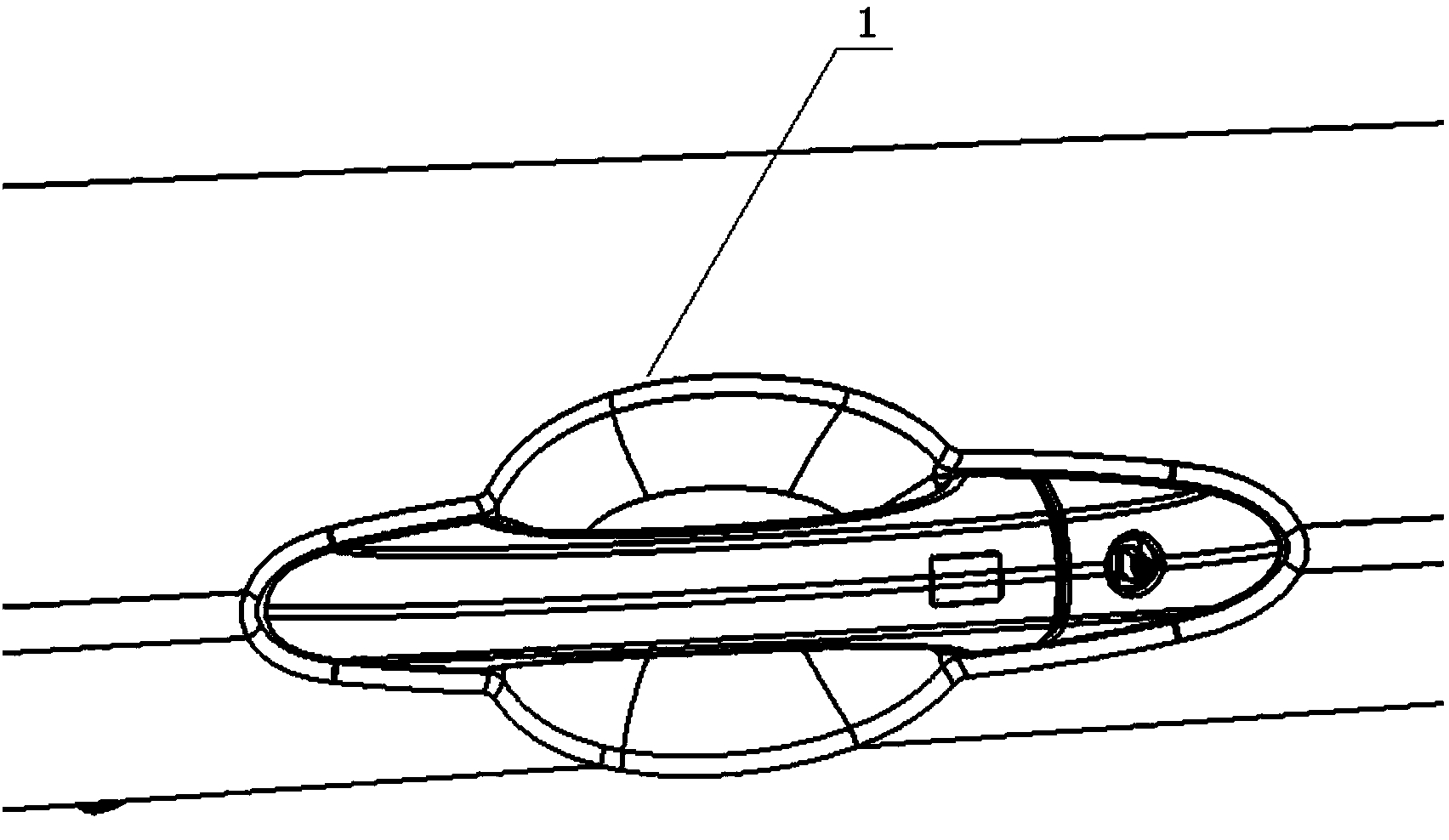

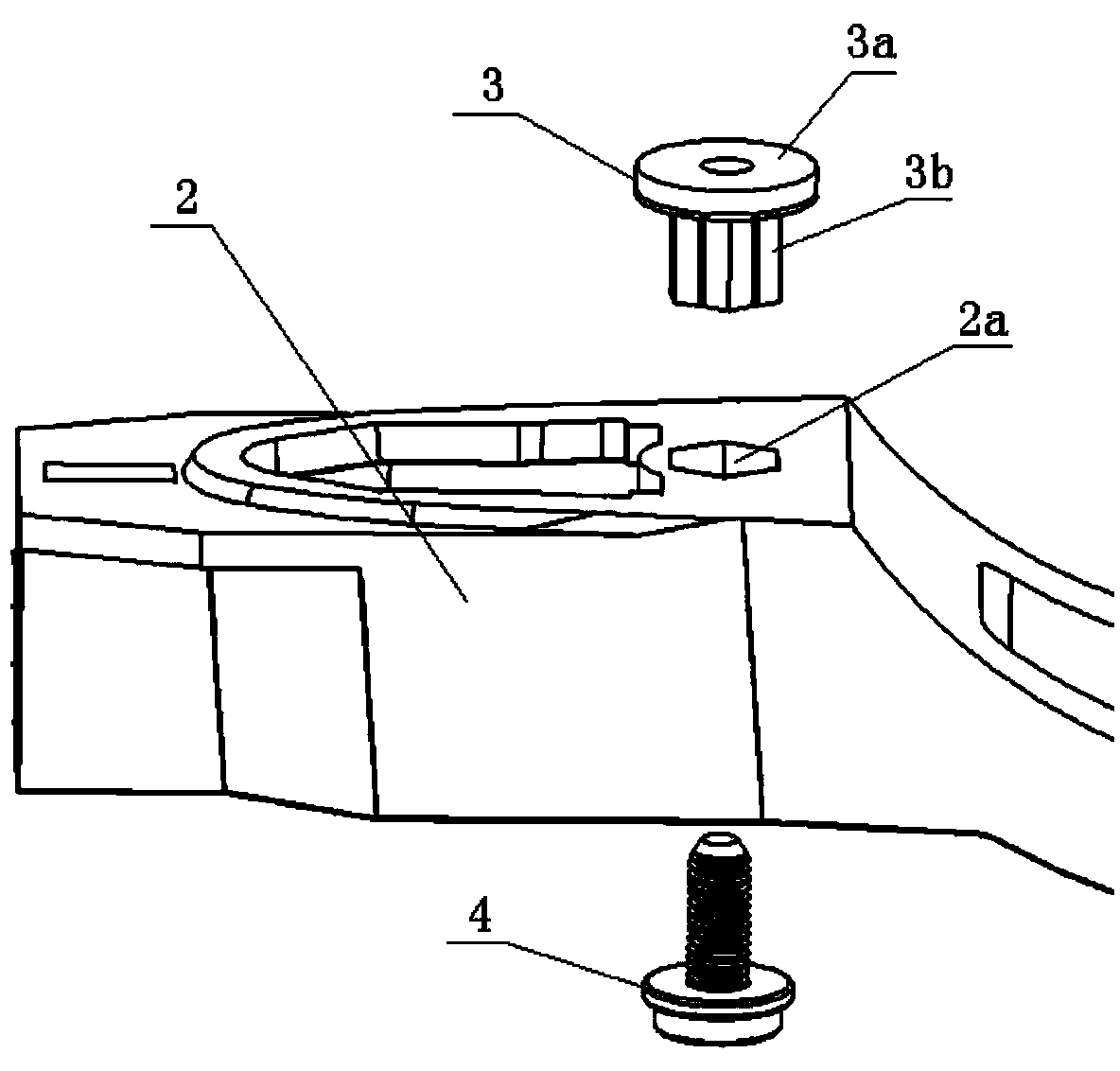

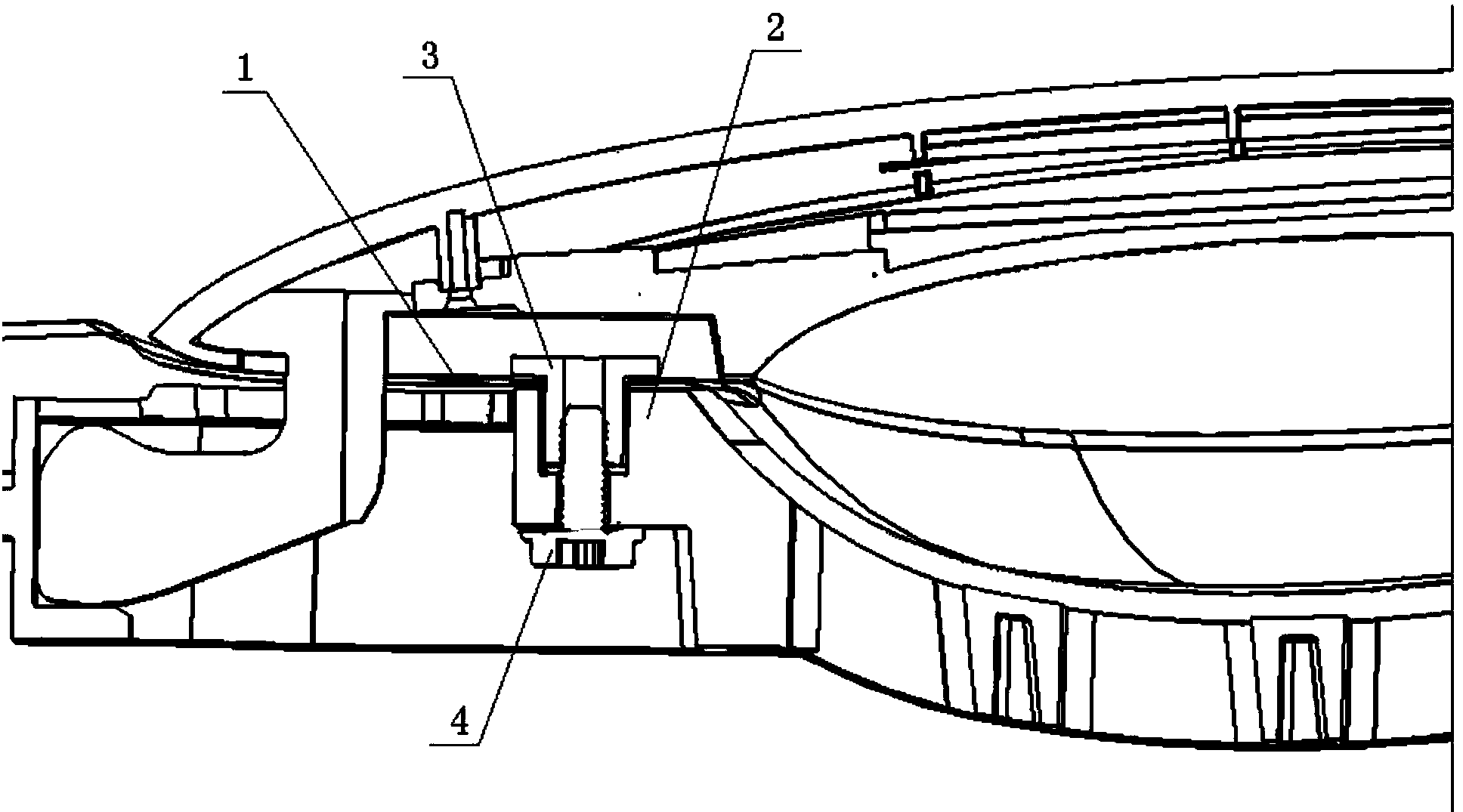

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] Such as Figure 1~Figure 3 As shown, the automobile door handle fixing structure in the embodiment includes a door handle base 2, the inner surface of the door handle base 2 is close to the outer surface of the door sheet metal 1, and is fixed on the door sheet metal 1 by steel T-shaped nuts 3 and matching screws 4. Metal 1; one end of the steel T-shaped nut 3 is provided with a brim 3a, and the brim 3a is buckled into the fixing hole on the door sheet metal 1; the inside surface of the door handle base 2 is provided with a mounting hole 2a , the main body 3b of the steel T-nut 3 is inserted into the installation hole 2a, and the outer surface of the door handle base 2 is provided with a through hole concentric with the installation hole 2a, and the screw 4 passes through the through hole from the outside to the inside. Insert it into the steel T-nut 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com