Shaft assembly pressing and rotating return device

A return device and shaft technology, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of increasing defective products in batches, unsafe human body, unevenness and instability, etc., and achieve easy follow-up maintenance, Ease of stand movement and reduced risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

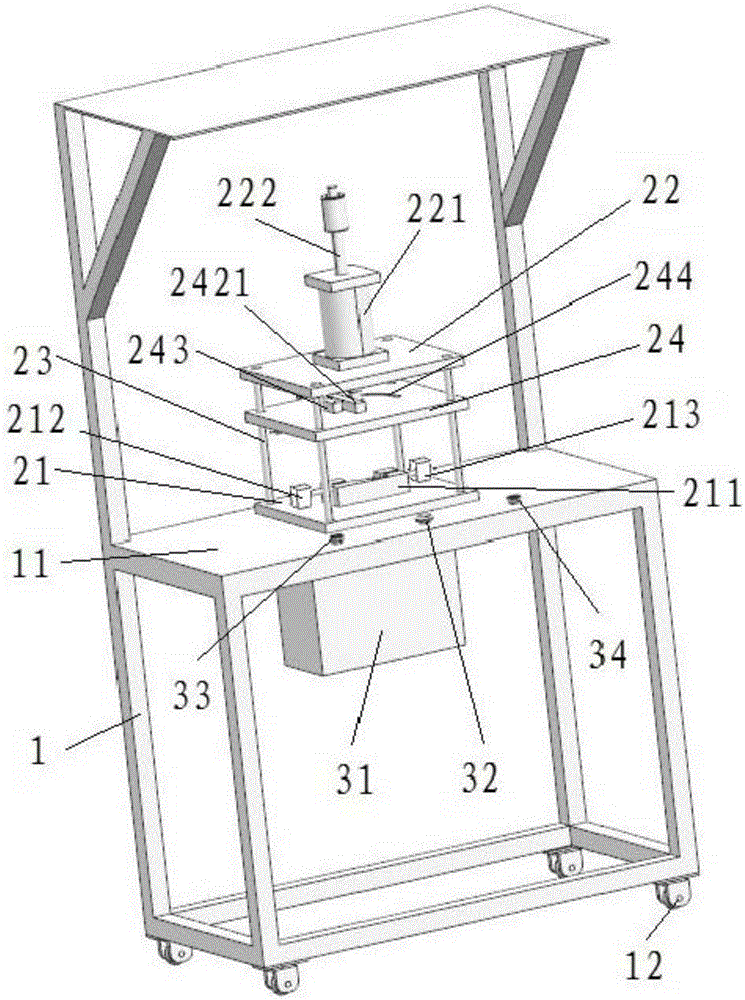

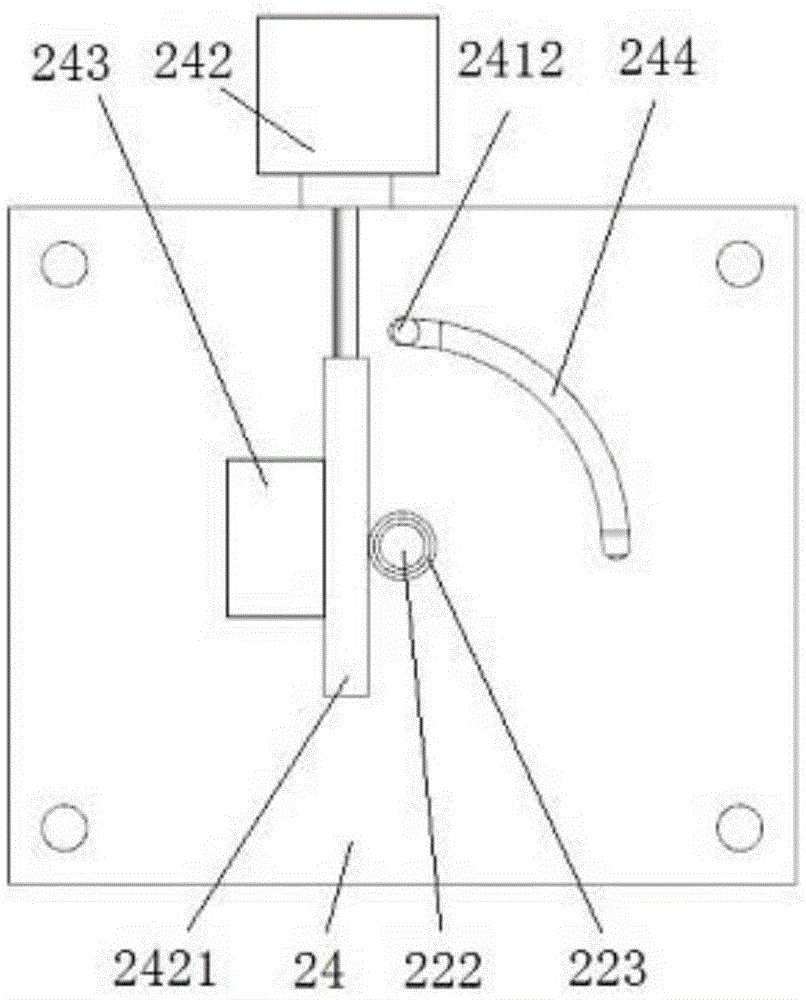

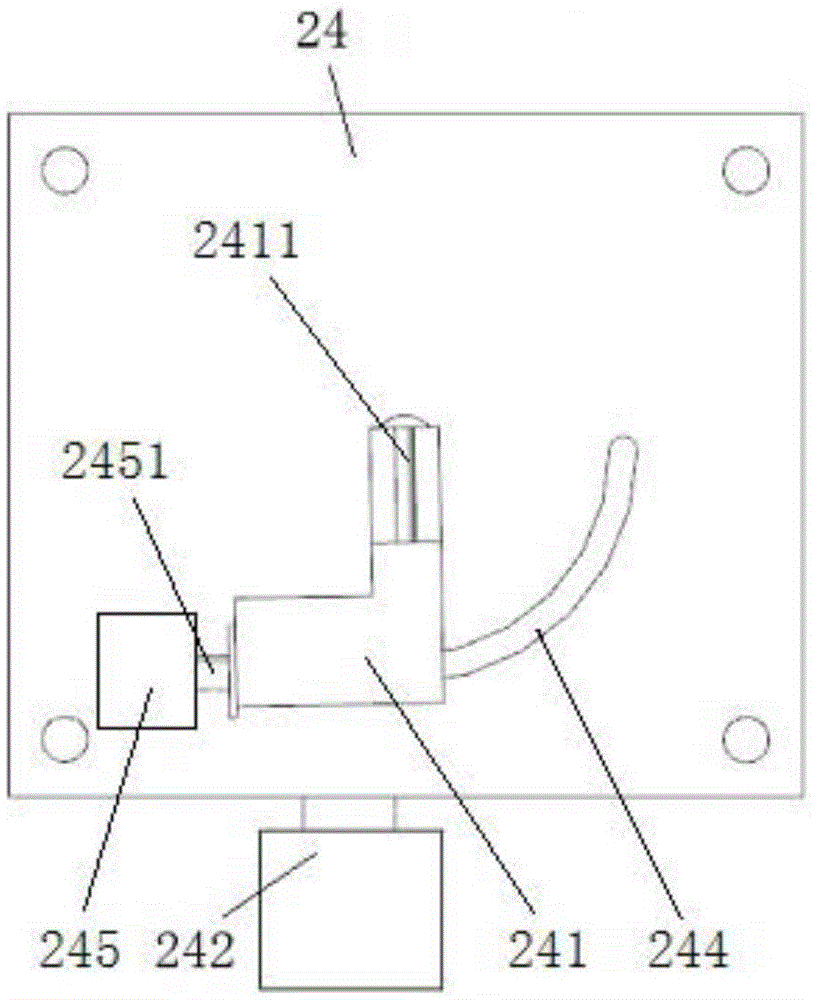

[0035] Such as Figure 1 to Figure 4 As shown, the pressing and rotating return device of the shaft assembly is used for the assembly of the shaft 41 and the shaft seat 42 of the automobile sun visor, which includes a bracket 1 with a platform 11 and a lower fixing plate 21 arranged on the platform. , be located at the upper fixed plate 22 above the lower fixed plate 21, connect the upper fixed plate 22 and 4 slide bars 23 of the lower fixed plate 21, be located between the upper fixed plate 22 and the lower fixed plate 21 and can move along the slide bar 23 The slide plate 24 that slides, the upper carrier 241 that is located on the lower surface of the slide plate 24 and is used for positioning the shaft rod 41, is fixed on the top of the upper fixed plate 22 and is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com