Lightweight reinforced structure paste gun

A structure-strengthening, lightweight technology, applied in the field of paste guns, can solve the problem that the actual thrust cannot be effectively improved, and achieve the effect of reducing weight and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the drawings and embodiments. It should be noted that in the following description, similar components are denoted by the same numbers.

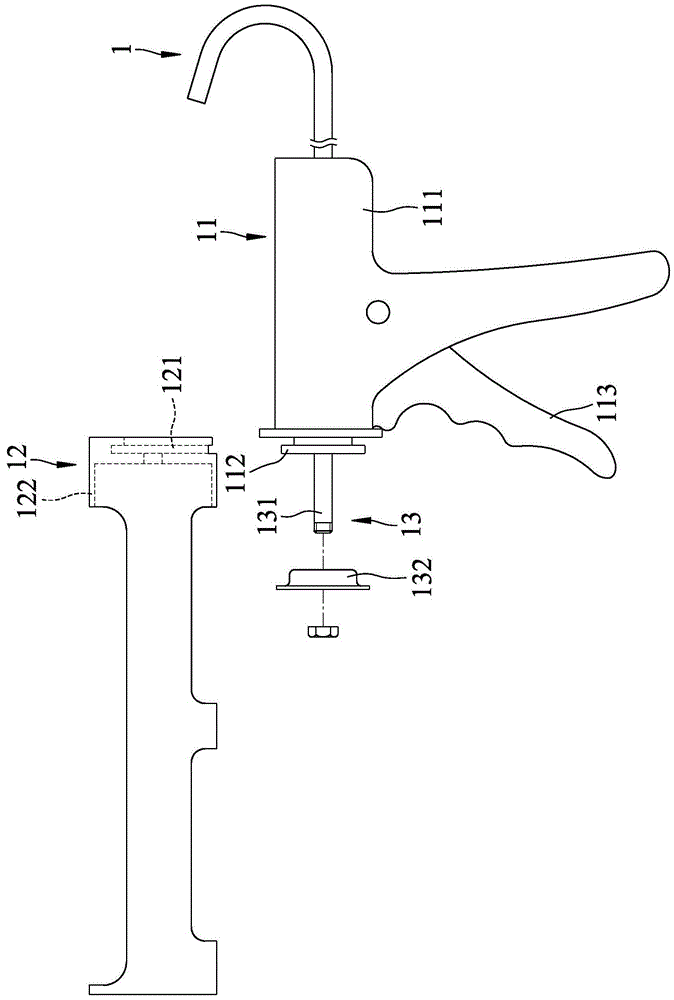

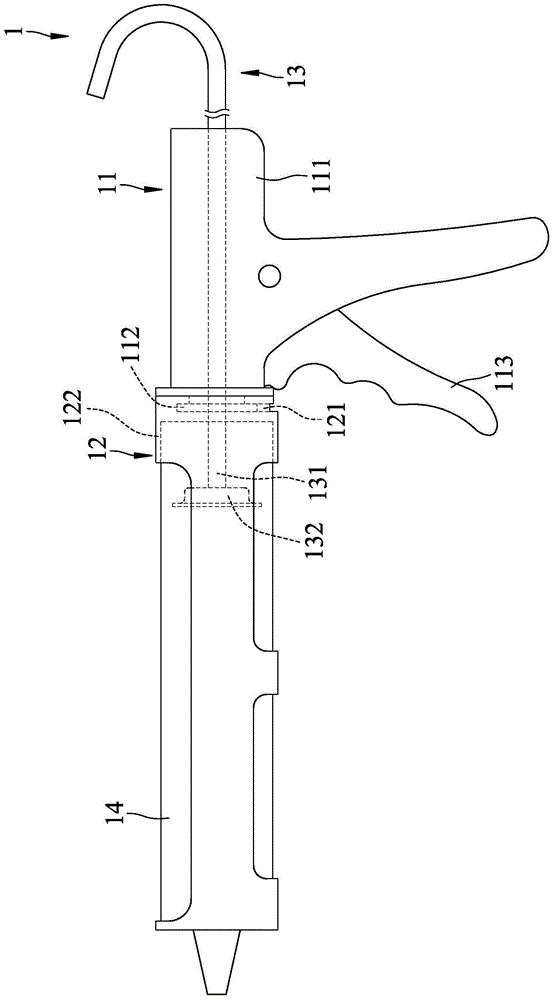

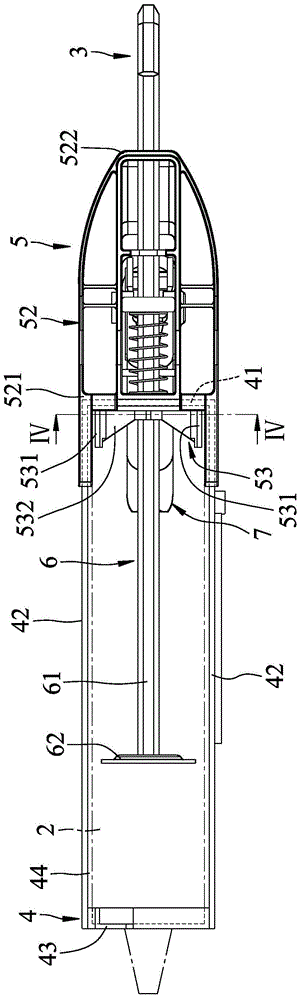

[0028] refer to image 3 , Figure 4 and Figure 5 , the first preferred embodiment of the paste gun with a lightweight reinforced structure of the present invention is suitable for use with an object to be extruded 2 and includes a handle unit 3 and a bracket 4 .

[0029] The grip unit 3 includes a plastic body 5 , a propulsion unit 6 , and a trigger 7 pivotally mounted on the body 5 .

[0030] The body 5 has a handle 51 for pivoting the trigger member 7 , a chamber 52 for accommodating the propelling unit 6 , and a limiting member 53 .

[0031] The gun bore 52 has a front end 521 close to the bracket 4 and a rear end 522 opposite to the front end 521 .

[0032] One end of the handle 51 is disposed between the front end 521 and the rear end 522 , and has an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com