Multi-arm automatic balancing mechanism of window cleaning machine

An automatic balancing and articulated arm technology, which is applied to window cleaning, cleaning equipment, household appliances, etc., can solve the problems of increased bearing capacity, limited space size, and increased production costs of window cleaners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

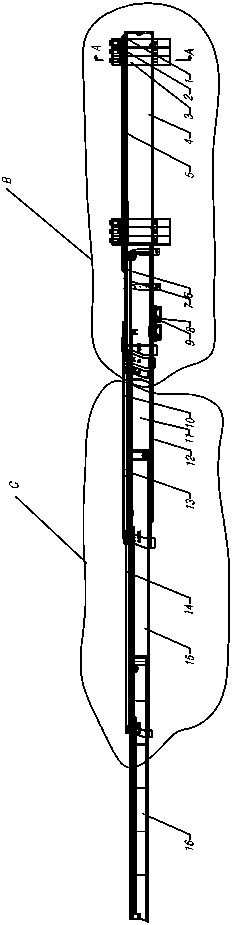

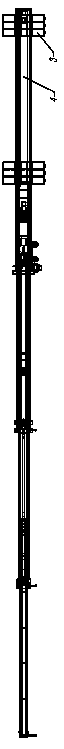

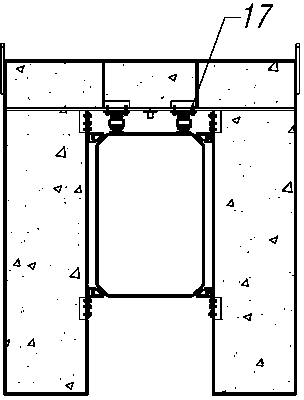

[0011] As shown, the invention includes a multi-section boom and a balancing device. The multi-section arm adopts a socket-type four-section linkage telescopic arm mechanism, including a geared motor, a rack 12, a gear 9, a traction chain 7, a traction chain 10, a traction chain 13, a traction chain 14, a fixed arm 4, two Joint arm 11, three joint arms 15, four joint arms 16. Geared motor is contained in fixed arm 4 bottoms, and tooth bar 12 is installed in two section arms 11 bottoms, and the output shaft 8 of geared motors is connected with tooth bar 12 by gear 9. Independent fixed arm 4, two-section arm 11, three-section arm 15, and four-section arm 16 are connected in series as a whole by traction chain 7, traction chain 10, traction chain 13, and traction chain 14 respectively. The balance device is installed on the fixed arm 4 . Described balancing device comprises counterweight 3, traveling pulley 17, first chain 2, first sprocket 1, second chain 5 and second spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com