Method for cleaning the seat of a double seat valve and double seat valve for performing the method

一种双座阀、清洁的技术,应用在升阀、阀装置、运输和包装等方向,能够解决易发生故障构造、双座阀复杂、不适用应用领域等问题,达到减小泄漏排出口的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

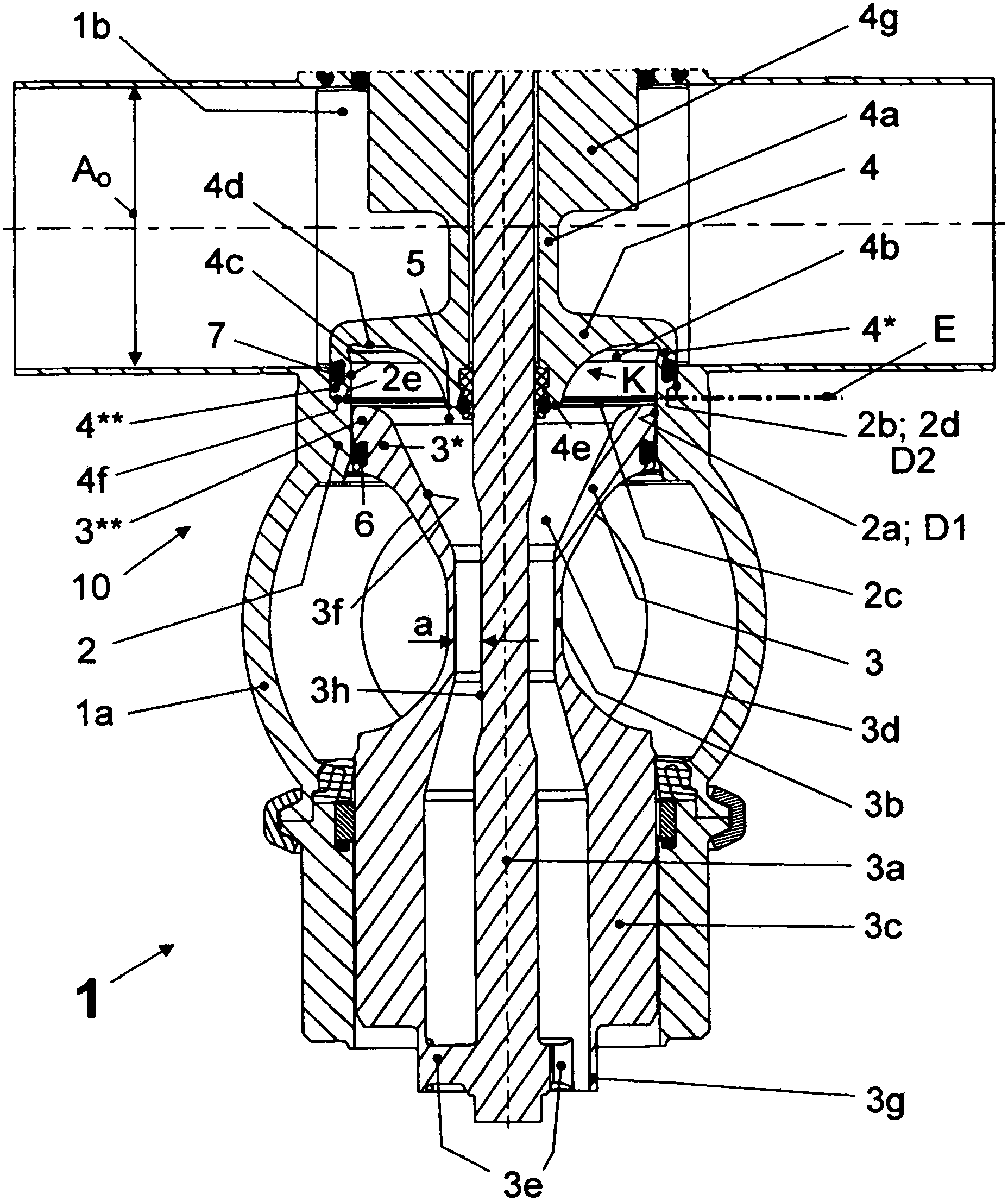

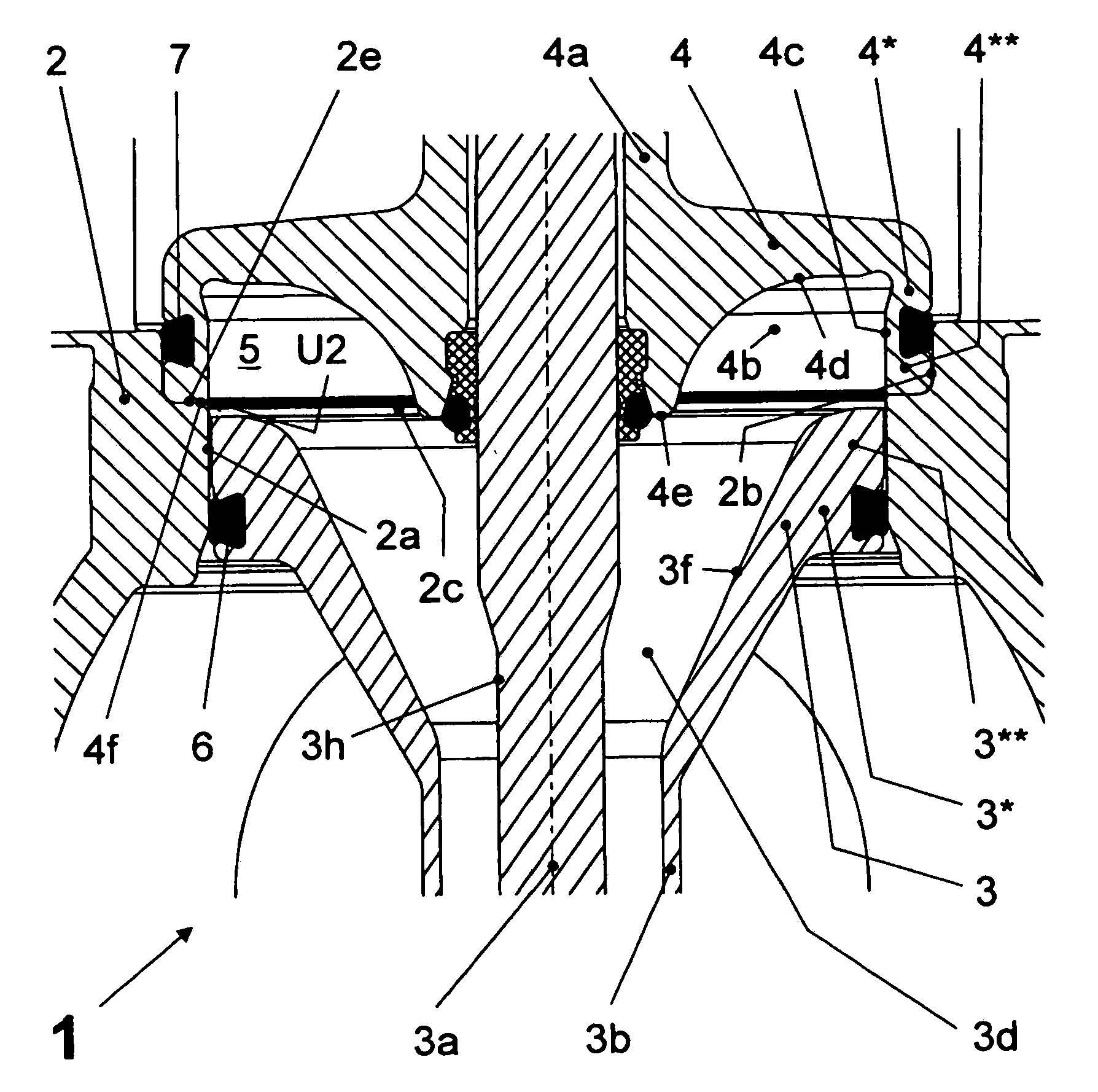

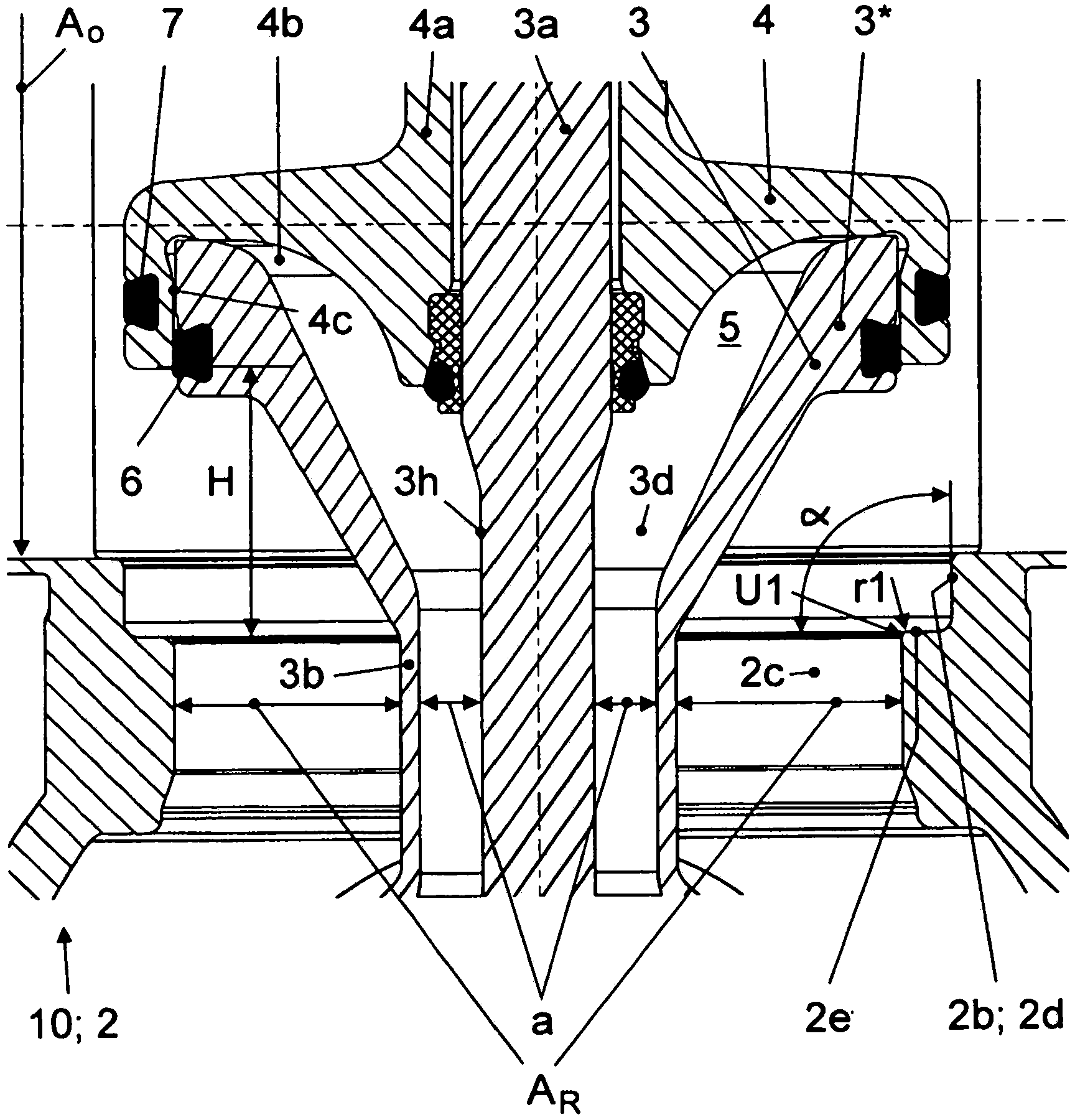

[0062] According to the double seat valve 1 of the present invention ( figure 1 , 1a ) mainly includes: a valve body 10 with a first and a second valve body part 1a or 1b, two independently movable closing members 3 and 4 with respectively configured adjustment rods 3a or 4a and a seat ring 2, said The seat ring establishes the connection between the valve body parts 1a, 1b via the connection opening 2c on the inside.

[0063] In the closed position of the double-seat valve 1 , the first closing part 3 (active closing part) configured as a slide valve piston is seated sealingly in the first seat surface 2 a of the cylindrical seat surface formed by the connection opening 2 c . For this purpose, a first seal 6 is provided in the slide valve piston 3 , which interacts with the first seat surface 2 a only by means of a radial pretension (radial seal with sliding engagement). In the closed position of the double-seat valve 1 , the second closing part 4 , which is likewise desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com