High altitude power transmission line ice scraper

A technology for high-altitude transmission lines and transmission lines, applied in electrical components, overhead installation, cable installation, etc., can solve problems such as troubles in electric power construction departments, increased weight of transmission lines, and easy snow and ice accumulation on transmission lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

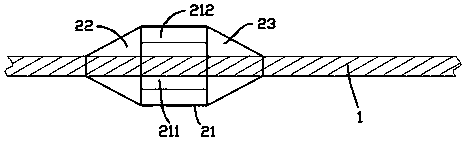

[0019] Such as figure 1 As shown, the high-altitude power line ice scraper includes a non-rotating body 21; the non-rotating body 21 is sleeved on the outer periphery of the power line 1, and the shaft hole that the non-rotating body 21 matches with the power line has a smooth surface; the non-rotating body 21 can slide linearly along the transmission line 1; the two ends of the non-rotating body 21 are symmetrically matched with a pair of rotating bodies 22 and 23 that are also sleeved on the outer periphery of the power line 1; the rotating body and the non-rotating body pass through the annular chute Cooperate so that the rotating bodies 22 and 23 can freely rotate around the axis of the non-rotating body 21 , that is, the axis of the transmission line 1 .

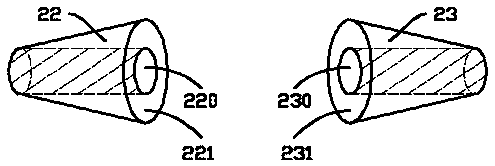

[0020] An example of the rotating body 22, 23 is figure 2 As shown, the surface of the shaft hole 220...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com