Aisle-stack stereoscopic garage driven by linear motors

A linear motor and three-dimensional garage technology, which is applied in the direction of the building, building type, and building where cars are parked, to achieve the effects of less wearing parts, high operation efficiency and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

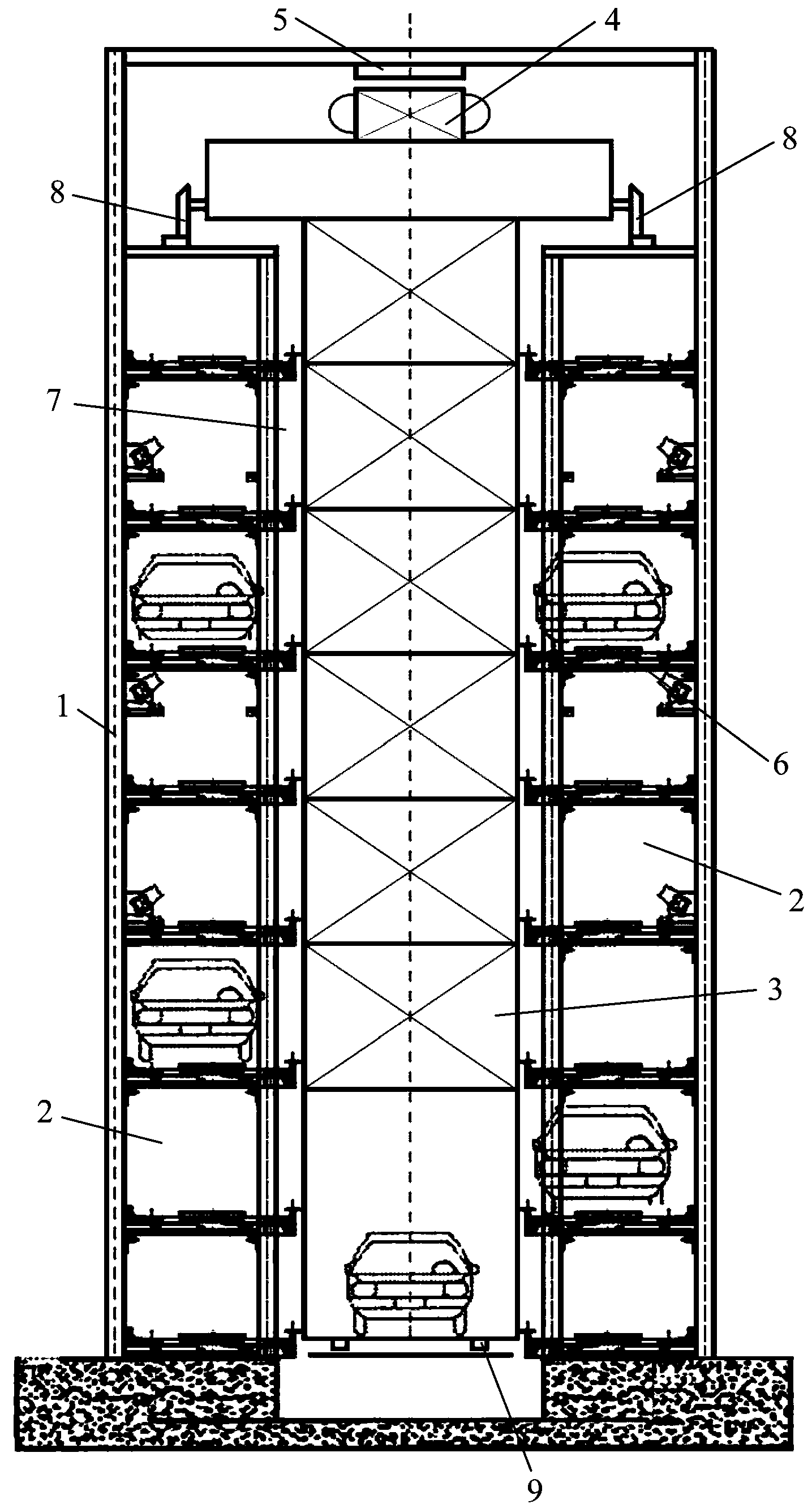

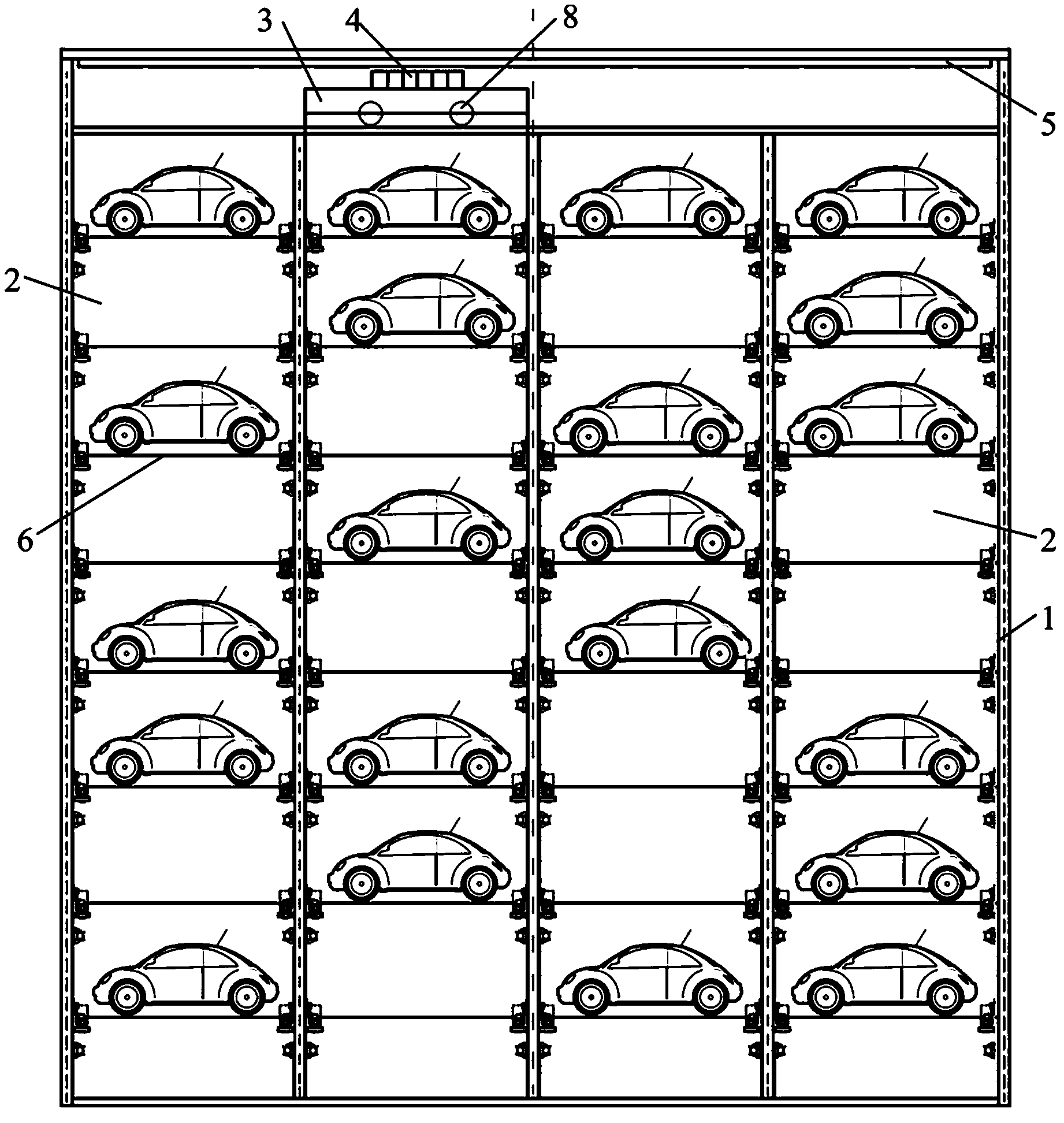

[0023] Please refer to figure 1 as well as figure 2 As shown, the preferred embodiment of the roadway stacking three-dimensional garage driven by the linear motor of the present invention includes a warehouse frame 1, a plurality of parking spaces 2, a stacking motion lifting platform 3, a lifting platform driving device, and a laterally moving vehicle loading plate 6 , channel 7 and channel layer track device 8.

[0024] The traversing vehicle carrying plate (6) is arranged on the stacking type motion lifting platform (3), the channel 7 is set in the middle part of the warehouse rack 1, and the stacking type moving lifting platform 3 is set in the channel 7. A row of parking spaces 2 is respectively arranged on the left and right sides of the channel 7 . A plurality of parking spaces 2 are stacked and arranged along the length direction of the storage rack 1 . The channel layer track device 8 is arranged on the top of the parking space 2, and the channel layer track devic...

Embodiment 2

[0029] The difference between this embodiment and the previous embodiment is only that: the bottom of the stacking type motion lifting platform 3 is provided with an auxiliary rail device 9, and the auxiliary rail device 9 includes rollers that are arranged on the bottom of the stacking type motion lifting platform 3 and The track that is arranged on the bottom surface of the library shelf 1. The stability and safety of the longitudinal movement of the stacking motion lifting platform 3 can be greatly enhanced. Other parts of the structure of this embodiment are completely the same as those of the previous embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com