Sodium pyrosulfite automatic batching and adding alkali device and method

A sodium pyrosulfite and automatic batching technology, applied in the field of sodium pyrosulfite batching system, can solve the problems of prolonging the production cycle, heavy cleaning workload, increasing energy consumption, etc., and achieve the goal of improving production automation, reducing physical labor, and improving product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

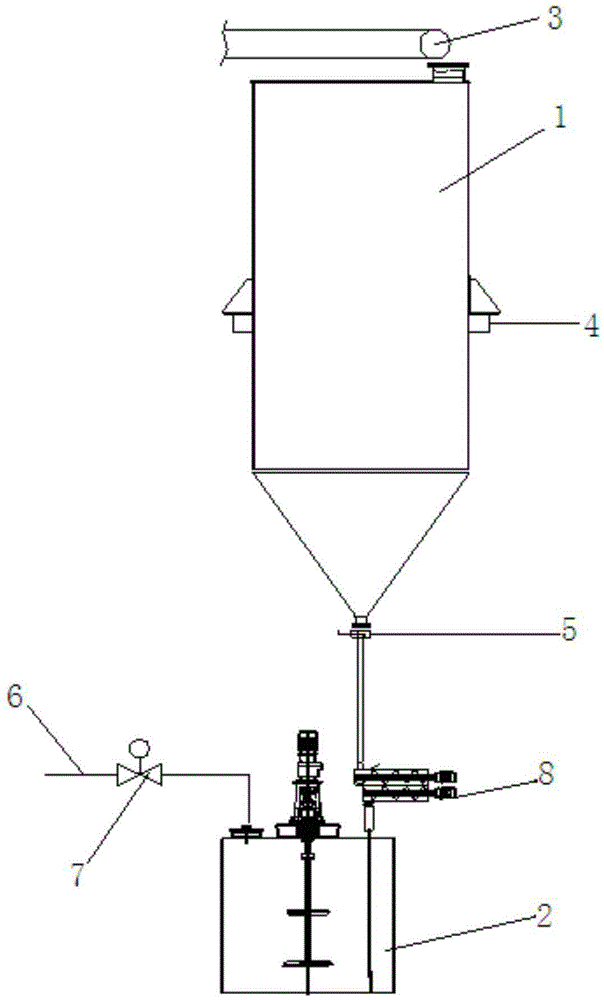

[0014] see figure 1 , an automatic sodium pyrosulfite batching and adding alkali device, including a soda ash silo 1, a soda mixing tank 2, the top of the soda ash silo 1 is provided with a feeding port, and the feeding port is connected with a soda ash feeding conveyor belt 3 driven by a motor , the soda ash silo 1 is equipped with a weighing device composed of a plurality of load cells 4, the bottom of the soda ash silo 1 is provided with a discharge port, and a plug valve 5 is installed at the discharge port, and the soda ash tank 2 is arranged on the soda ash Below the discharge port of silo 1, there is a feed inlet on the top of soda distribution tank 2, and the soda distribution tank 2 is also connected with a water inlet pipe 6, and a water regulating valve 7 driven by a motor is installed on the water inlet pipe 6, which is located in the soda ash silo 1 A frequency conversion speed regulation double-pipe screw feeding scale 8 is set between the discharge port and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com