Suspension method of granules in suckable jelly and application method of the suspension method in preparation of the jelly

A technology for particulate matter and jelly, applied in the field of making jelly and the suspension of particulate matter in absorbable jelly, can solve the problems of uneven distribution, difficult to achieve automatic control, unsatisfactory suspension, etc. Ideal or less automated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

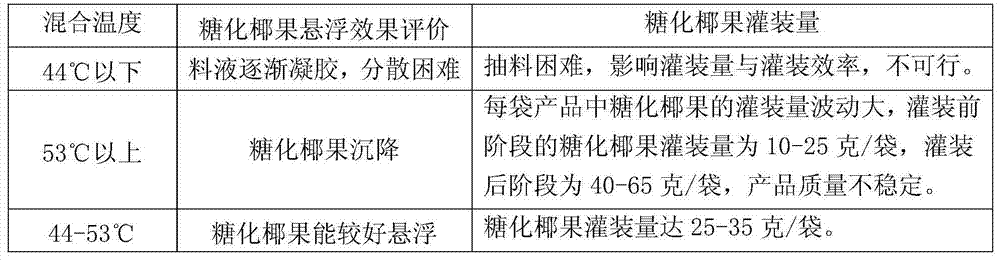

Embodiment 1

[0030] Add 60-70 parts of process water into the cooking tank, mix 14-18 parts of white sugar, 0.1-0.15 parts of carrageenan, and 0.07-0.1 parts of purified konjac powder, put them into the cooking tank, and heat up the liquid in the cooking tank Keep warm at 98°C for 5 minutes; when the feed liquid cools down to 85°C, add 2-3 parts of concentrated apple juice preheated to 40-50°C, 0.2-0.24 parts of malic acid dissolved in boiling water, 0.12-0.18 parts Potassium chloride and 0.1-0.3 parts of sodium citrate, stir and mix evenly, measure the sugar content of the jelly liquid after cooking; prepare the sugar content of the granules with a size of 5-10mm*5-10mm*5-10mm into the jelly liquid Within the range of sugar content ±0.5%, wait for the jelly feed liquid to cool down to 44-53°C, add it to the feed liquid, and use a stirring shaft with an angle of 35° between the stirring shaft and the vertical direction to stir for 3 minutes at 20-30r / min; The obtained feed liquid is filled...

Embodiment 2

[0033] Add 65 parts of process water into the cooking tank, mix 16 parts of white sugar, 0.12 parts of carrageenan, and 0.09 parts of purified konjac powder into the cooking tank, and heat the material liquid in the cooking tank to 98°C for 5 minutes; When the feed liquid cools down to 85°C, add 2.5 parts of concentrated apple juice preheated to 45°C, 0.22 parts of malic acid dissolved in boiling water, 0.15 parts of potassium chloride and 0.2 parts of sodium citrate, stir and mix evenly, and measure the cooking time. The sugar content of the jelly material liquid after the material is 16.7%; adjust the sugar content of the jelly block with a size of 5mm*5mm*5mm to 16.7%, wait for the jelly material liquid to cool down to 53°C, add it to the material liquid, and use a stirring shaft and a vertical Stir with a stirring shaft at an angle of 35° at 20r / min for 3 minutes; fill the mixed material liquid into penguin bags, and then sterilize in a water bath at 85°C for 25 minutes; pl...

Embodiment 3

[0035] Add 65 parts of process water into the cooking tank, mix 16 parts of white sugar, 0.12 parts of carrageenan, and 0.09 parts of purified konjac powder into the cooking tank, and heat the material liquid in the cooking tank to 98°C for 5 minutes; When the feed liquid cools down to 85°C, add 2.5 parts of concentrated apple juice preheated to 45°C, 0.22 parts of malic acid dissolved in boiling water, 0.15 parts of potassium chloride and 0.2 parts of sodium citrate, stir and mix evenly, and measure the cooking time. The sugar content of the jelly feed liquid is 16.7%; the sugar content of the saccharified coconut fruit with a size of 10mm*10mm*10mm is adjusted to 16.7%, and the jelly feed liquid is cooled to 50°C, then added to the feed liquid, using a stirring shaft and Stir with a stirring shaft at a vertical angle of 35° at 25r / min for 3 minutes; fill the mixed material into penguin bags, and then sterilize in a water bath at 85°C for 25 minutes; place the sterilized jelly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com