Three-dimensional surface topography measuring method for large-size workpiece

A three-dimensional surface and surface topography technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problem of sacrificing lateral resolution and achieve the effect of high lateral resolution information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

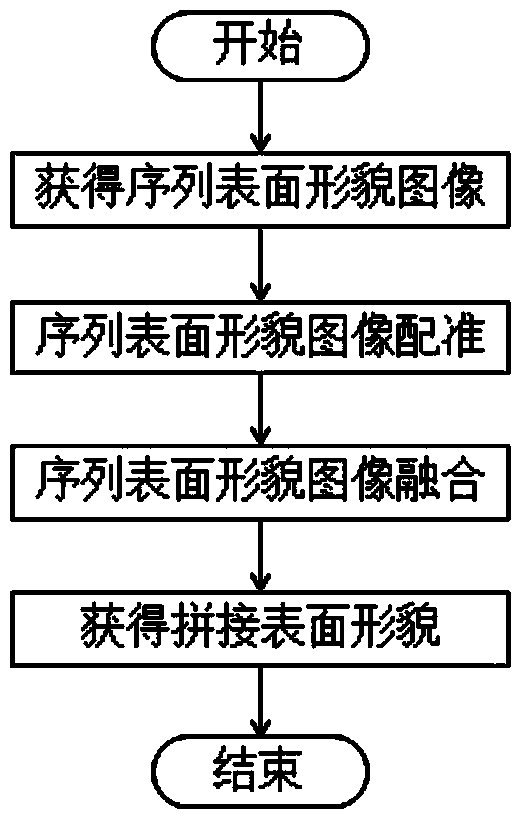

[0097] like figure 1 As shown, the three-dimensional surface topography image measurement method of a large-scale workpiece includes the following steps:

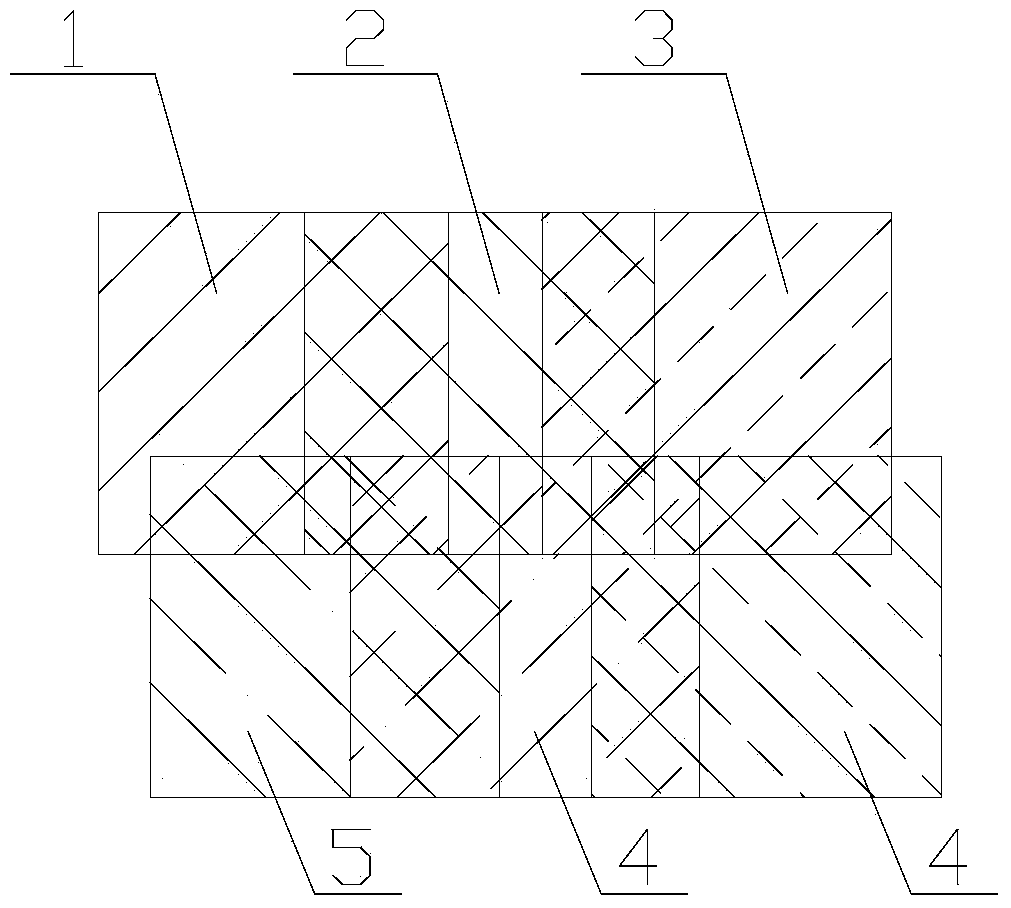

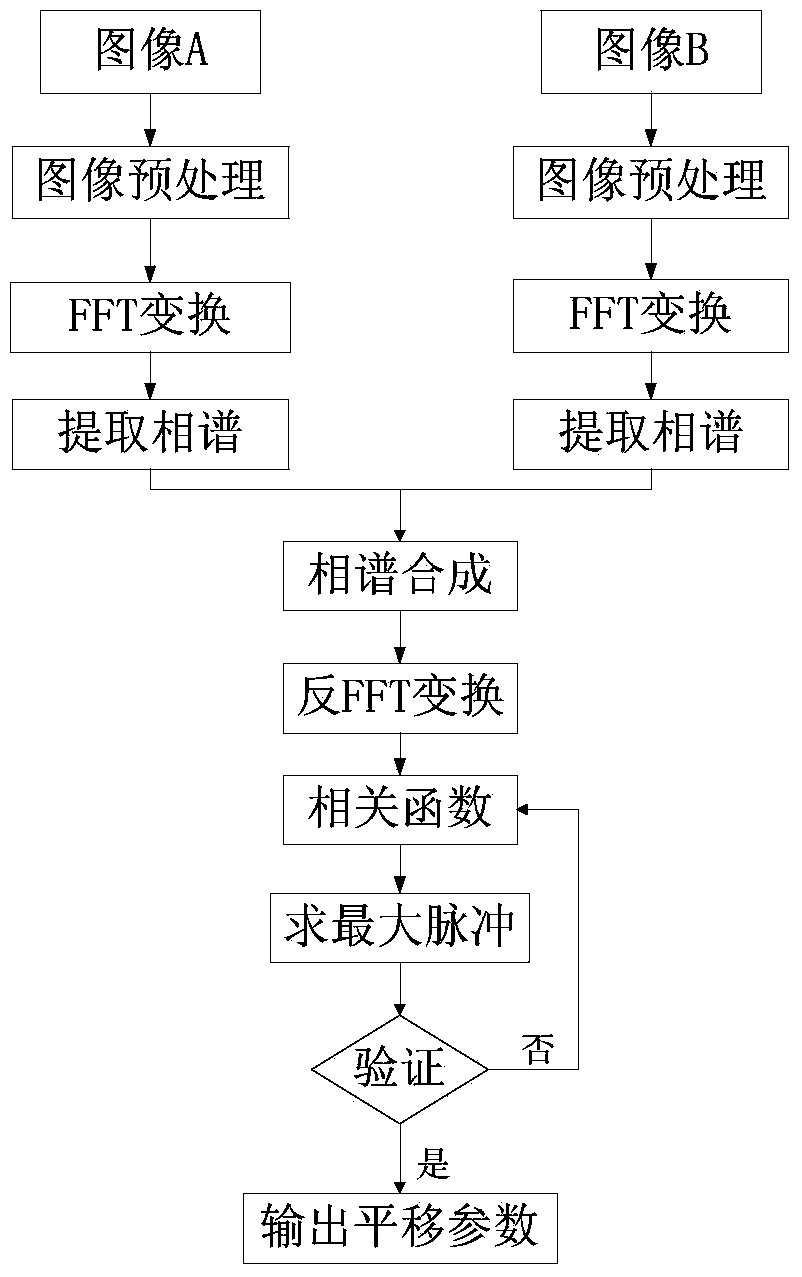

[0098] 1) Use the white light wavelength scanning interferometry method to scan the surface of the workpiece. The white light wavelength scanning interferometry method acquires a series of sub-surface images. During the scanning process, the measured workpiece moves along a serpentine shape, and there are overlapping areas between adjacent sub-surface images. The subsurface images compose the sequence surface topography. After the measurement is completed, the adjacent images of an image can be known through the motion path, such as figure 2 As shown, for example, the adjacent images numbered 2 can only be numbers 1, 3, 4, 5, and 6. If there are sequence images above image 2, three more images need to be added in the same way. In the actual registration process, because numbers 1 and 3 are before and after the measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com