A Cutting Arm Structure Favorable for Bearings to Keep Lubricated

A bearing holding and cutting arm technology, applied in cutting machinery, earth-moving drilling, etc., can solve the problems of lack of lubricating oil, shortened bearing service life, roadheader failure, etc. The effect of the service life and the reduction of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

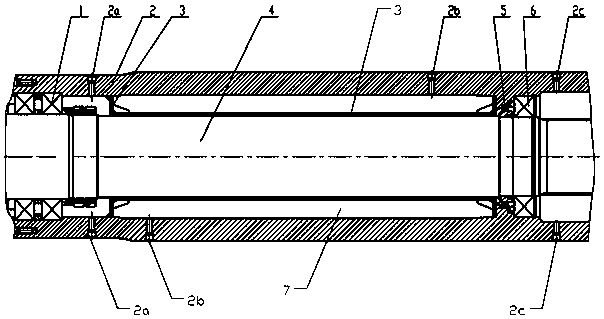

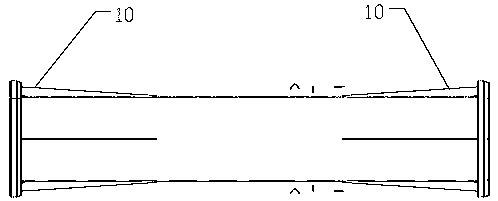

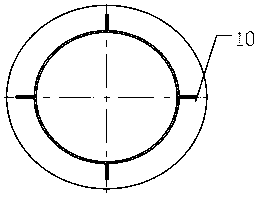

[0014] Such as figure 1 and image 3 As shown, a cutting arm structure that is beneficial to keep the bearings lubricated includes an outer cylinder 2, a main shaft 4, a rotary oil seal 5, a front end bearing 1, and a rear end bearing 6. The rear end bearing 6 is connected with the outer cylinder 2, and an inner cylinder 3 is arranged between the outer cylinder 2 and the main shaft 4. The inner cylinder 3 is located between the front end bearing 1 and the rear end bearing 6. The two ends of the inner cylinder 3 are connected to the The inner wall of the outer cylinder 2 is sealed and connected. There is a sealed cavity volume 7 between the inner cylinder 3 and the outer cylinder 2. There is a first oil storage space between the left end of the inner cylinder 3 and the front end bearing 1. The rotary oil seal 5 Installed between the right end of the inner cylinder 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com