Air lock of carbon fiber pre-oxidation equipment

A carbon fiber and pre-oxidation technology, applied in the field of air locks, can solve the problems of waste of resources, inability to meet the needs of fiber technology, long carbon fiber residence time, etc., and achieve the effects of convenient maintenance and disassembly, good sealing effect, and reliable process technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

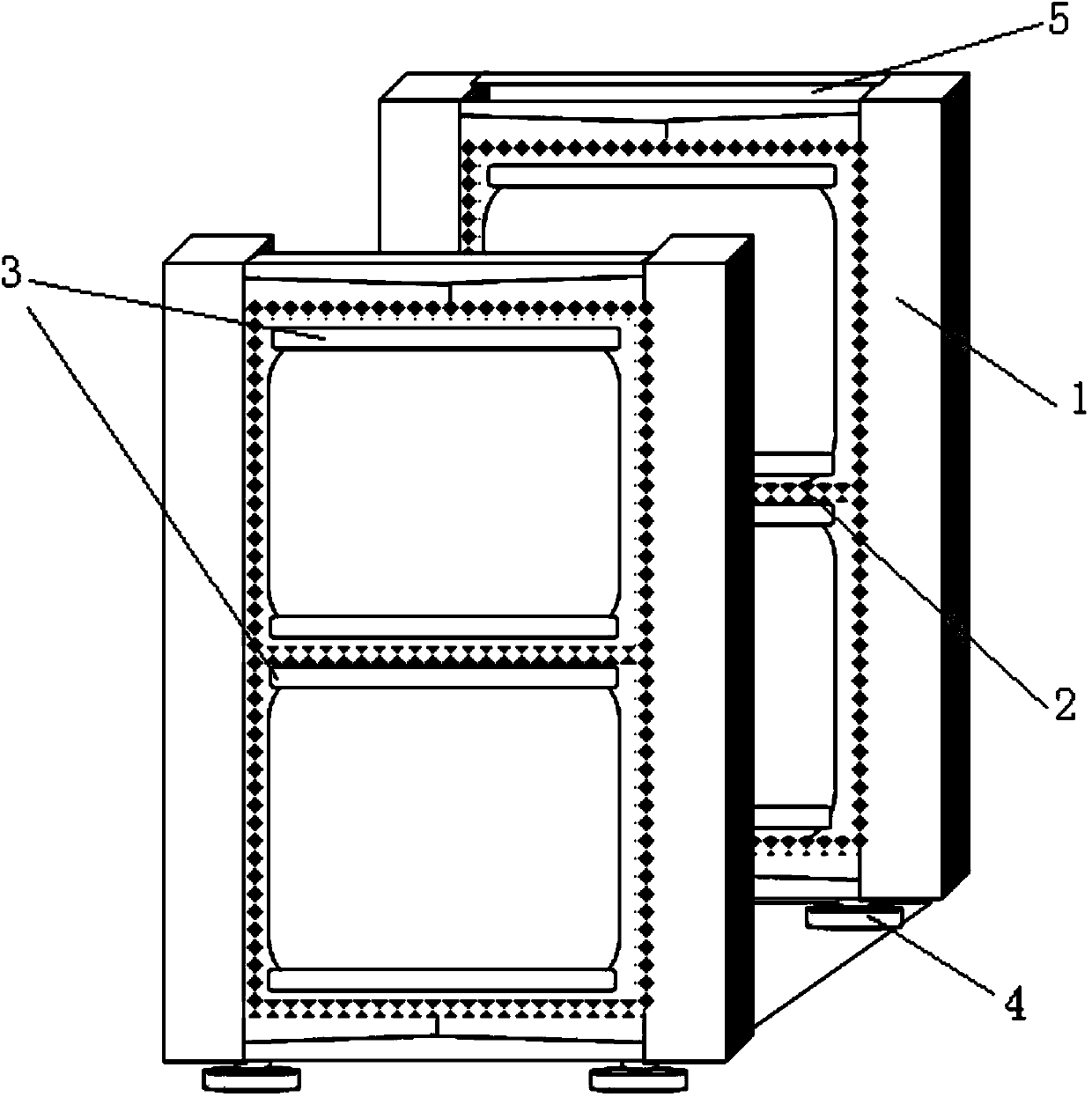

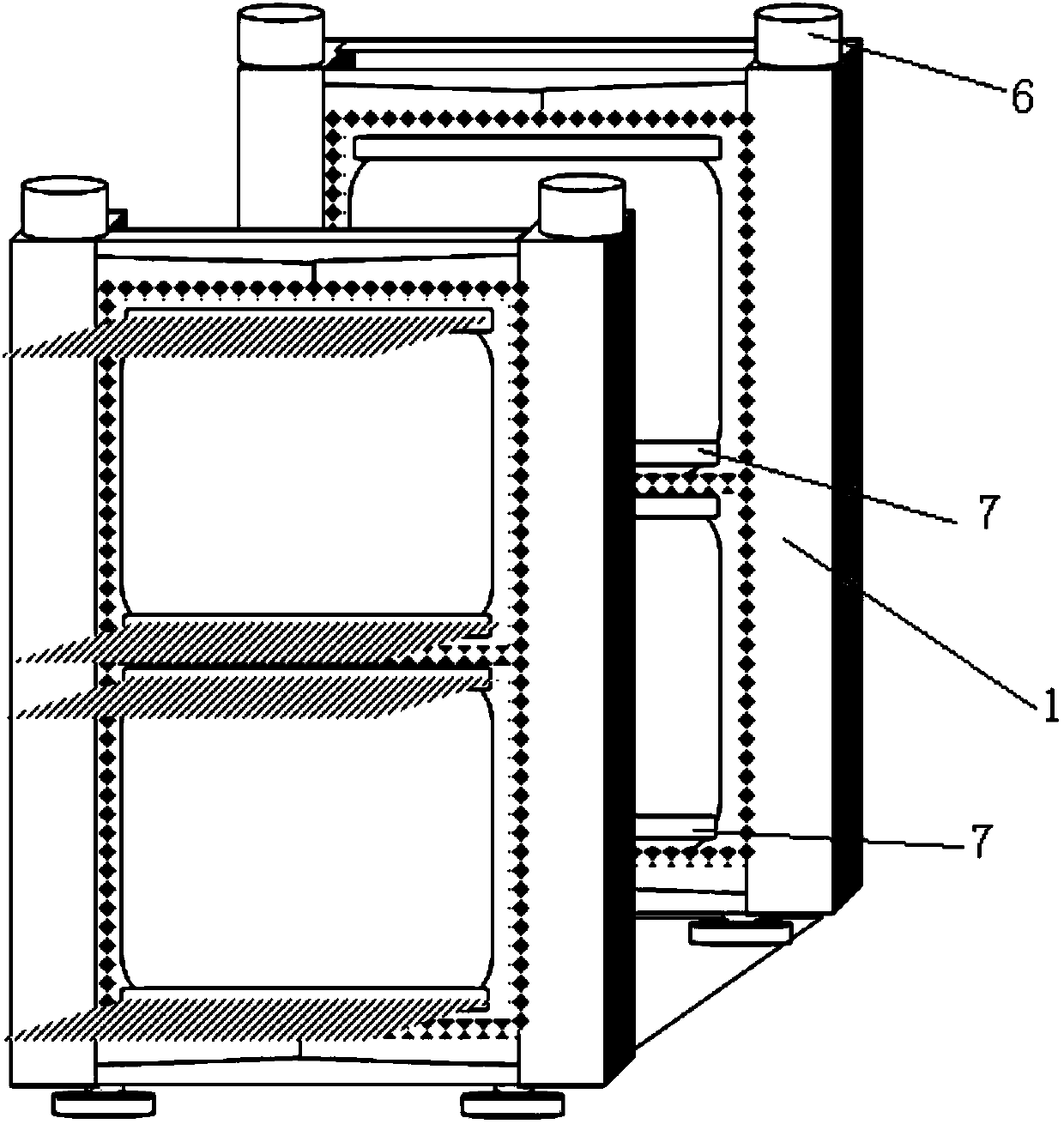

[0020] refer to Figure 1-2 As shown, the present invention provides an air lock for carbon fiber pre-oxidation equipment, including a pillar 1, a closing plate 2 and a base 4, the closing plate 2 is fixed between two pillars 1, and the closing plate 2 is provided with Carbon fiber inlet 3, carbon fiber outlet 7 and sealing gasket, base 4 is installed at the bottom of each pillar 1, and strong exhaust waste channel 6 is provided inside the pillar 1.

[0021] The air lock is installed at both ends of the pre-oxidation equipment by flange or lap connection, and a leak-proof gasket is provided between the air lock and the pre-oxidation equipment.

[0022] The base 4 can be freely adjusted in height and supports the overall weight of the air lock.

[0023] The closed plate 2 is provided with exhaust gas natural discharge holes 5, and the closed plate 2 is respectively provided with two carbon fiber inlets 3 and two carbon fiber outlets 7, and the closed plate 2 is made of stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com