Automatic filling and extraction system

An automatic filling and filling technology, which is used in barrel/cask filling, liquid filling, etc., can solve the problems of waste of human resources, cannot realize automatic positioning, and cannot fully realize automation, and achieve the effect of precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

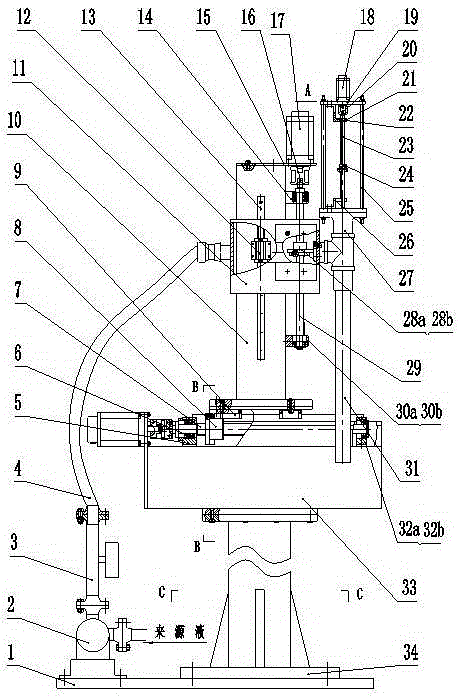

[0046] Describe in detail below in conjunction with accompanying drawing: As shown in the figure,

[0047] Structural connection of filling and extraction device Ⅰ: the variable pump 2 is fixed on the bottom plate 1 by bolts, the right end of the variable pump 2 is connected to the source liquid pipeline through the connecting flange, and the upper end is connected to the switching valve 3 through the connecting flange; the switching valve 3 The variable pipeline 4 is connected with the branch 37 on the variable valve 27; the left end of the variable valve 27 is fixedly connected with the valve connecting plate 40, the upper end is connected with the lower connecting plate 43, and the filling rod 31 is installed at the lower end; the valve connecting plate 40 is connected by bolts Connected with the vertical mobile platform 11, the lower connection plate 43 is connected and fixed with the upper connection plate 19 through the fixed column 25; the variable adjustment motor 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com