Anti-explosion hydraulic type shear fork elevator

A lift, hydraulic technology, applied in the field of explosion-proof hydraulic scissor lift, can solve the problems of poor safety performance, labor, low efficiency, etc., and achieve the effects of convenient operation, improved work efficiency and safety performance, and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

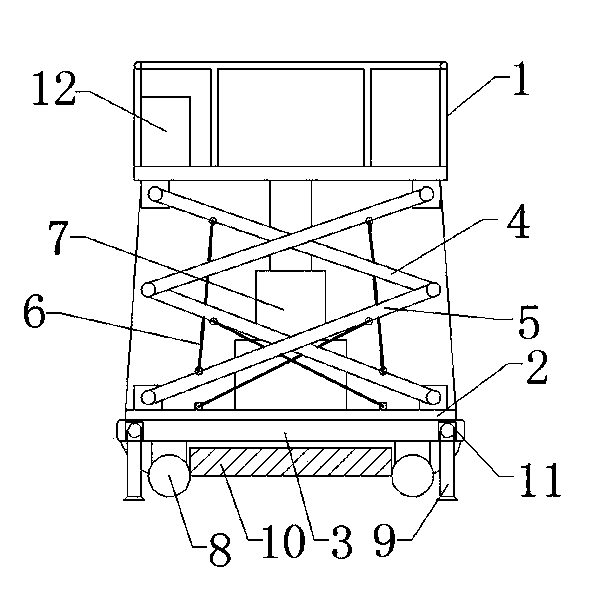

[0015] Such as figure 1 The shown explosion-proof hydraulic scissor lift includes a guardrail mechanism 1, a rotary table 2 and a chassis 3; an inner bracket 4 and an outer bracket 5 hinged to each other are arranged between the guardrail mechanism 1 and the rotary table 2; its characteristics In that: the inner support 4, the outer support 5 and the turntable 2 are all connected with an oil cylinder device 6; a hydraulic mechanism 7 is arranged between the guardrail mechanism 1 and the middle part of the turntable 2; the turntable 2 is installed on the chassis 3, the upper end of the middle part; the chassis 3 is provided with a moving wheel 8, a hydraulic top 9 and a power supply device 10; the moving wheels 8 are installed on the bottom of the chassis 3; The left and right ends of the side; the power supply device 10 is installed inside the chassis.

[0016] Wherein, a baffle device is arranged on the outer side between the guardrail mechanism 1 and the rotating platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com