A kind of wood fastening device for woodworking band saw machine sports car

A band saw machine and wood technology, which is applied to band saws, wood processing appliances, sawing equipment, etc., can solve the problem of inability to fasten, and achieve the effects of simple fixing, saving wood resources, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

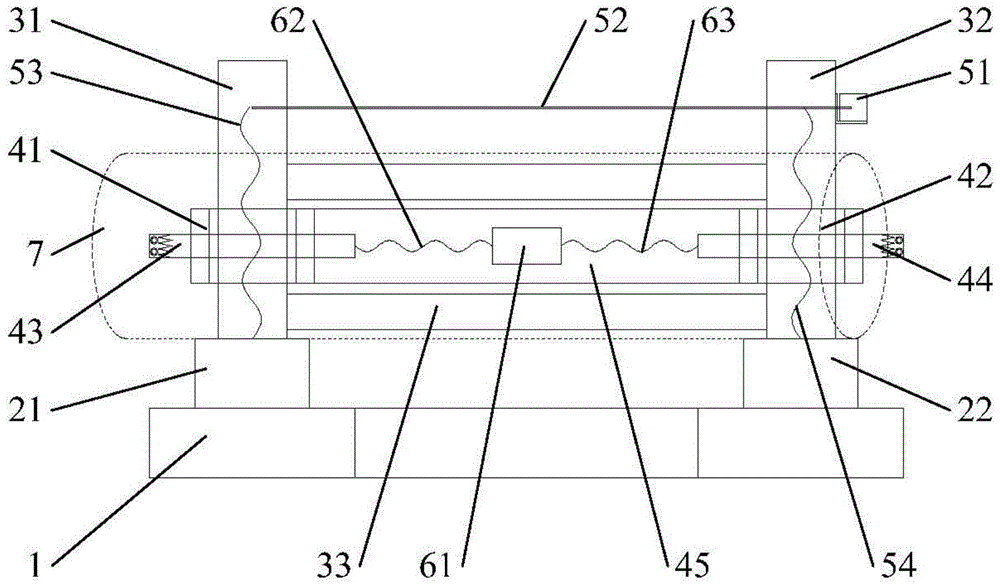

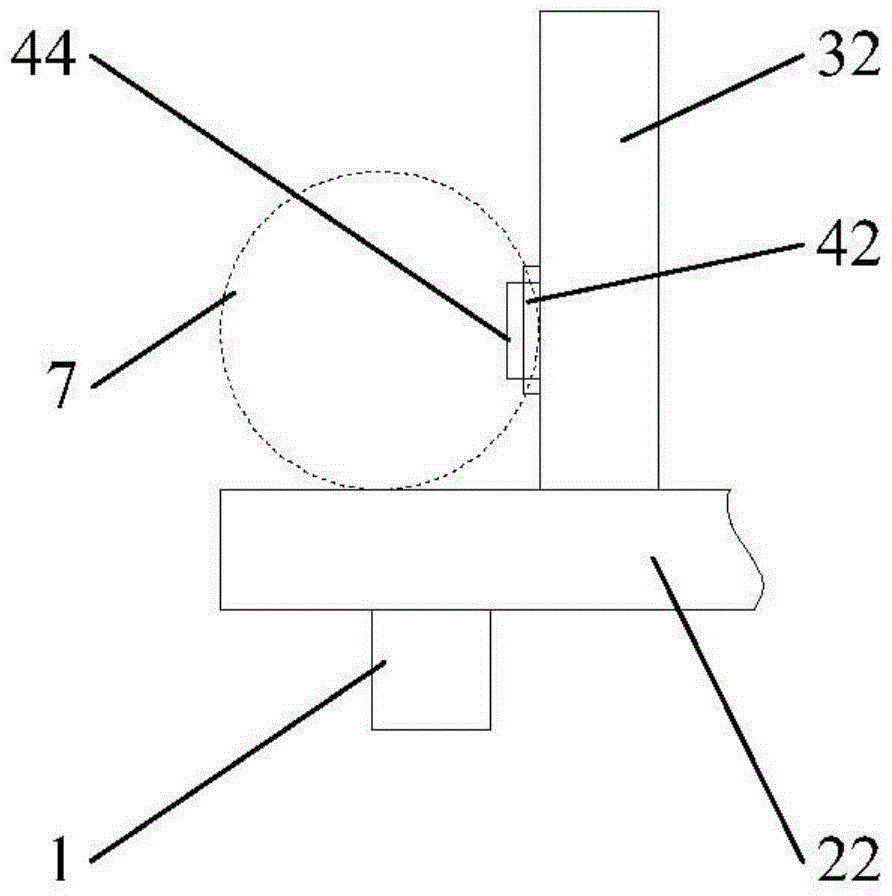

[0021] Such as figure 1 As shown, a woodworking band saw machine sports car wood fastening device of the present invention comprises a car body 1, a first backing rail 21, a second backing rail 22, a first column 31, a second column 32, a column connecting beam 33, a first Cross carriage 41, second cross carriage 42, first hook 43, second hook 44, carriage connecting arm 45, vertical transmission mechanism and horizontal transmission mechanism.

[0022] The first column 31 is vertically arranged on one end of the upper surface of the car body 1 through the first backing rail 21, the first post 31 is slidably fitted with the first backing rail 21, the first post 31 can move along the length direction of the first backing rail 21, the second The second column 32 is vertically arranged on the other end of the upper surface of the car body 1 through the second pad rail 22, the second column 32 is slidably fitted with the second pad rail 22, and the second column 32 can move along ...

Embodiment 2

[0028] A timber fastening device for a sports car of a woodworking band saw machine according to the present invention includes a car body 1, a first pad rail 21, a second pad rail 22, a first column 31, a second column 32, a column connecting beam 33, and a first cross slide 41. The second cross carriage 42, the first hook 43, the second hook 44, the carriage connecting arm 45, the vertical transmission mechanism and the horizontal transmission mechanism.

[0029] The first column 31 is vertically arranged on one end of the upper surface of the car body 1 through the first backing rail 21, the first post 31 is slidably fitted with the first backing rail 21, the first post 31 can move along the length direction of the first backing rail 21, the second The second column 32 is vertically arranged on the other end of the upper surface of the car body 1 through the second pad rail 22, the second column 32 is slidably fitted with the second pad rail 22, and the second column 32 can ...

Embodiment 3

[0035] A timber fastening device for a sports car of a woodworking band saw machine according to the present invention includes a car body 1, a first pad rail 21, a second pad rail 22, a first column 31, a second column 32, a column connecting beam 33, and a first cross slide 41. The second cross carriage 42, the first hook 43, the second hook 44, the carriage connecting arm 45, the vertical transmission mechanism and the horizontal transmission mechanism.

[0036] The first column 31 is vertically arranged on one end of the upper surface of the car body 1 through the first backing rail 21, the first post 31 is slidably fitted with the first backing rail 21, the first post 31 can move along the length direction of the first backing rail 21, the second The second column 32 is vertically arranged on the other end of the upper surface of the car body 1 through the second pad rail 22, the second column 32 is slidably fitted with the second pad rail 22, and the second column 32 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com