Gearbox machining method

A processing method and gearbox technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high scrap rate and low production efficiency in gearbox processing, achieve flexible and changeable production plans, and reduce labor costs. Strength and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing example:

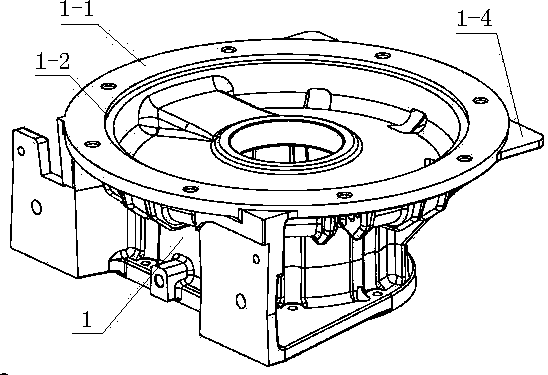

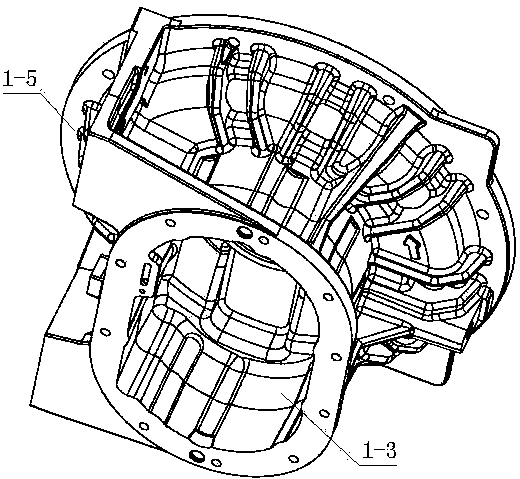

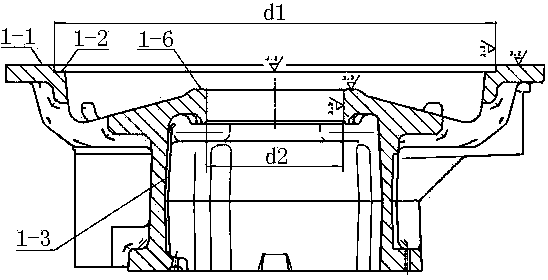

[0021] Figures 1 to 3 Shown is the gear box to be processed, the gear box 1 includes a box body part with waist-shaped holes 1-3 inside and a circular flange connected to the outer edge of one end of the box body part with two ear plates , the bottom surfaces of the two ear plates 1-4 and the bottom surface 1-5 of the circular flange are arranged on the same plane, and the circular flange has a bearing hole connected with the waist hole 1-3; There is a positioning spigot at 1-1 on the upper end surface of the circular flange. The bearing hole and the positioning hole of the locating spigot are arranged coaxially. The diameter of the bearing hole is d2, and the positioning hole of the locating spigot is The hole diameter is d1; according to the process requirements, the upper end surface 1-1 of the gear box round flange, the positioning hole of the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com