Potato skin production line

A production line and technology for stalk skin, applied in the field of stalk skin production line, can solve the problems of low production efficiency and high labor cost, and achieve the effects of high processing efficiency, reduced labor cost and good product taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

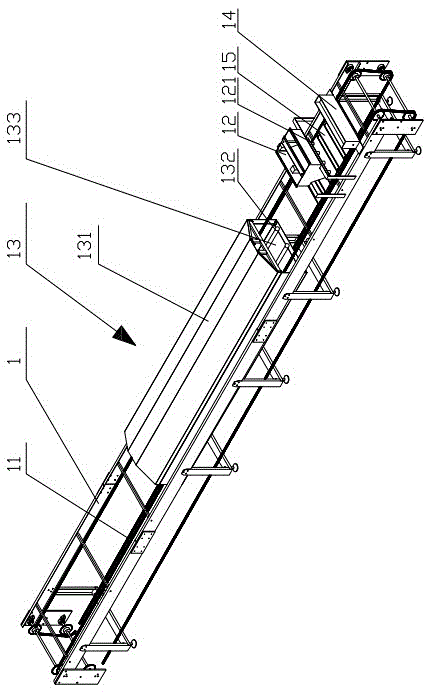

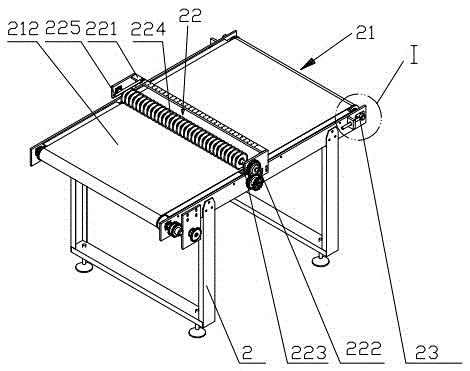

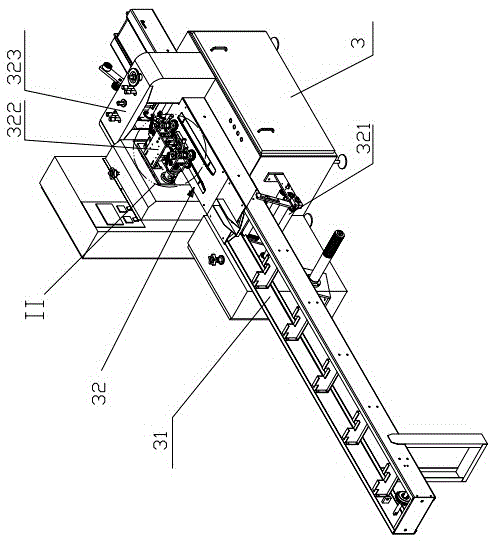

[0022] Depend on figure 1 combine figure 2 , 3 , Shown in 4 and 5, a kind of sweet potato skin production line, comprises first support 1, second support 2 and the 3rd support 3, described first support 1 is provided with first conveying device 11, is used for supplying to be processed The feeding device 12 of the raw material, the heating device 13 for heating the raw material to be processed and the automatic brushing device 14 for feeding the heated raw material, specifically, the described feeding device is a quantitative feeding device, Allows the feeding device to carry out quantitative grouting to the system. Described first conveying device 11 is provided with a plurality of forming discs 15, and described feeding device 12 is arranged on the top of forming disc 15, specifically, the first conveying device is an endless chain, can provide enough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com