Manual adjustable mechanism for testing the flicker value of LCD panel

A liquid crystal panel and scintillation value technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of low test efficiency, optical probe is not aligned with the liquid crystal panel to be tested, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

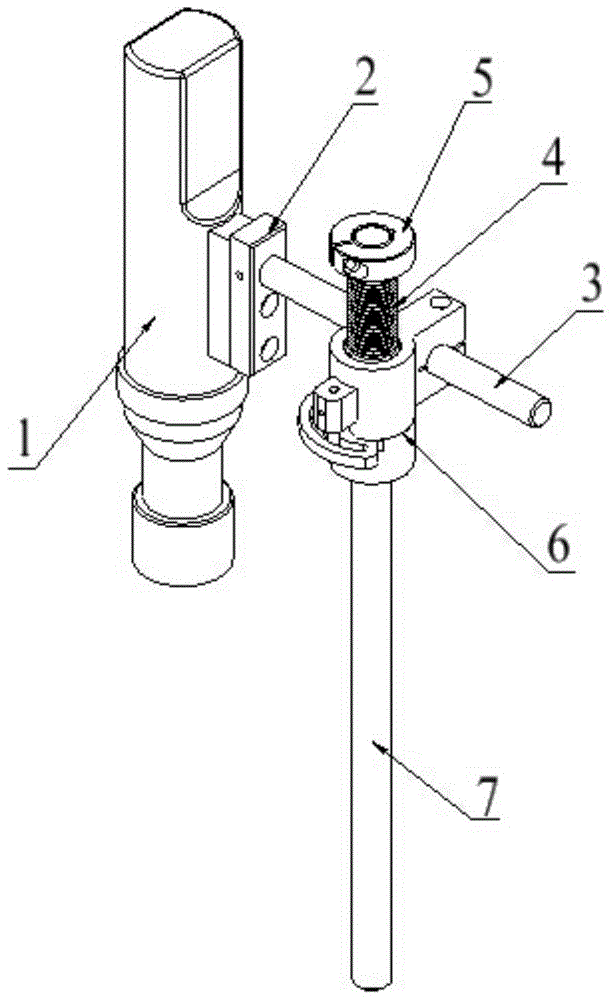

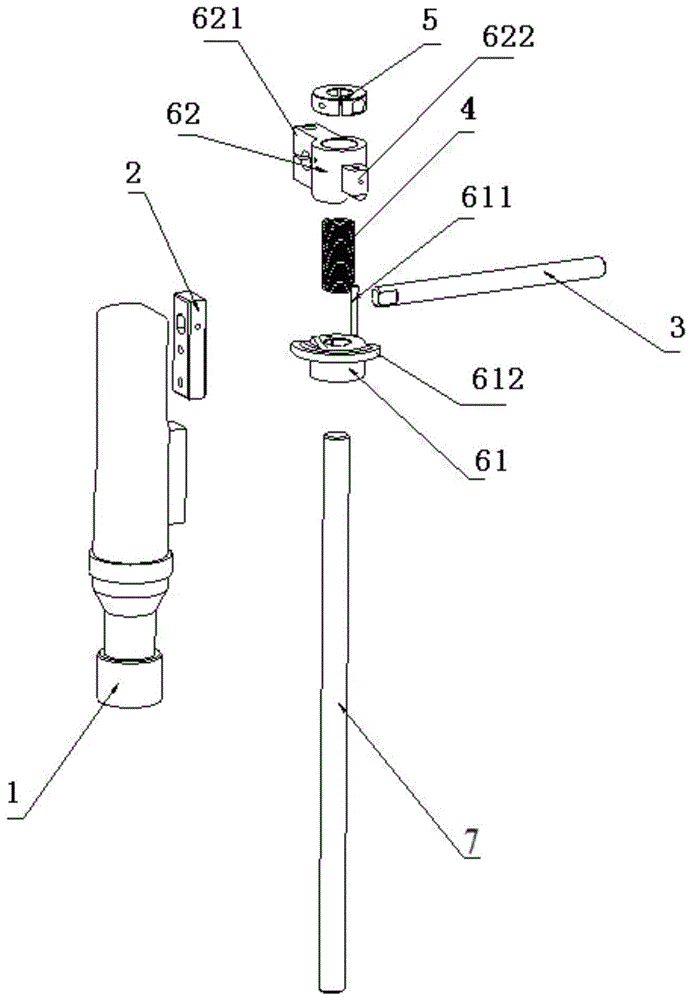

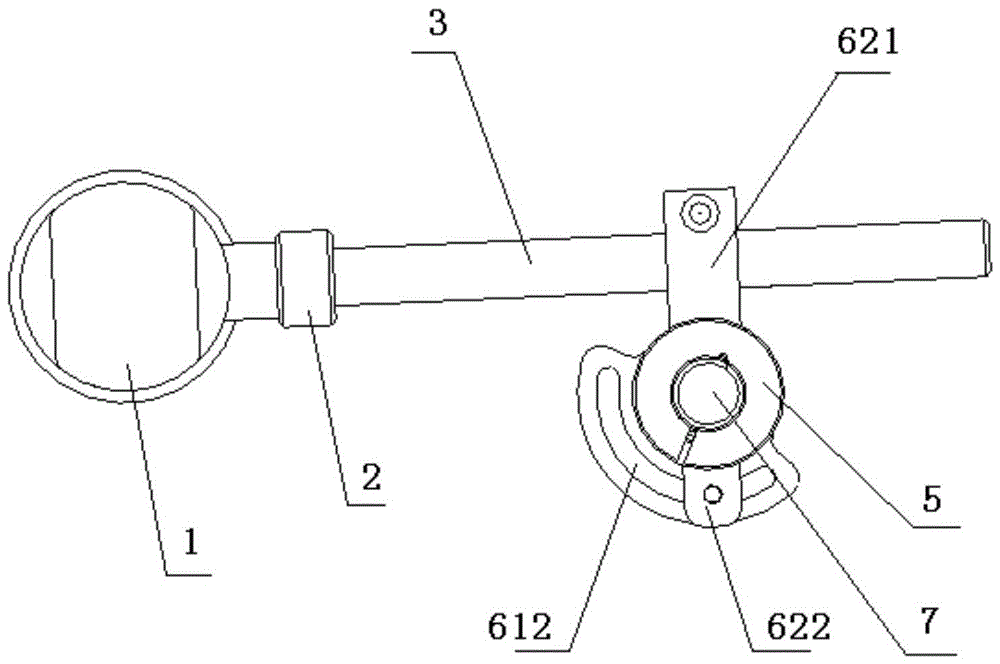

[0025] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a manually adjustable mechanism for testing the flicker value of a liquid crystal panel includes an optical probe module 1, a support bar 3, a rotation module 6 and a support vertical bar 7, and the rotation module includes a positioning base 61 and a rotating upper seat 62. The positioning base is positioned and sleeved on the supporting vertical rod, the rotating upper seat is disposed on the upper side of the positioning base, and the rotating upper seat is axially stopped and circumferentially rotated and sleeved on the supporting vertical rod, One side of the rotating upper base is provided with a clamping portion 621 , the support bar is slidably positioned on the clamping portion, and one end of the support bar is fixedly connected to the optical probe module through the connection block 2 . In the above structure, during specific implementation, the fixed connection between the strut cross bar and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com