Quantitative split-loading device and method

A technology of quantitative sub-packaging and valve device, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

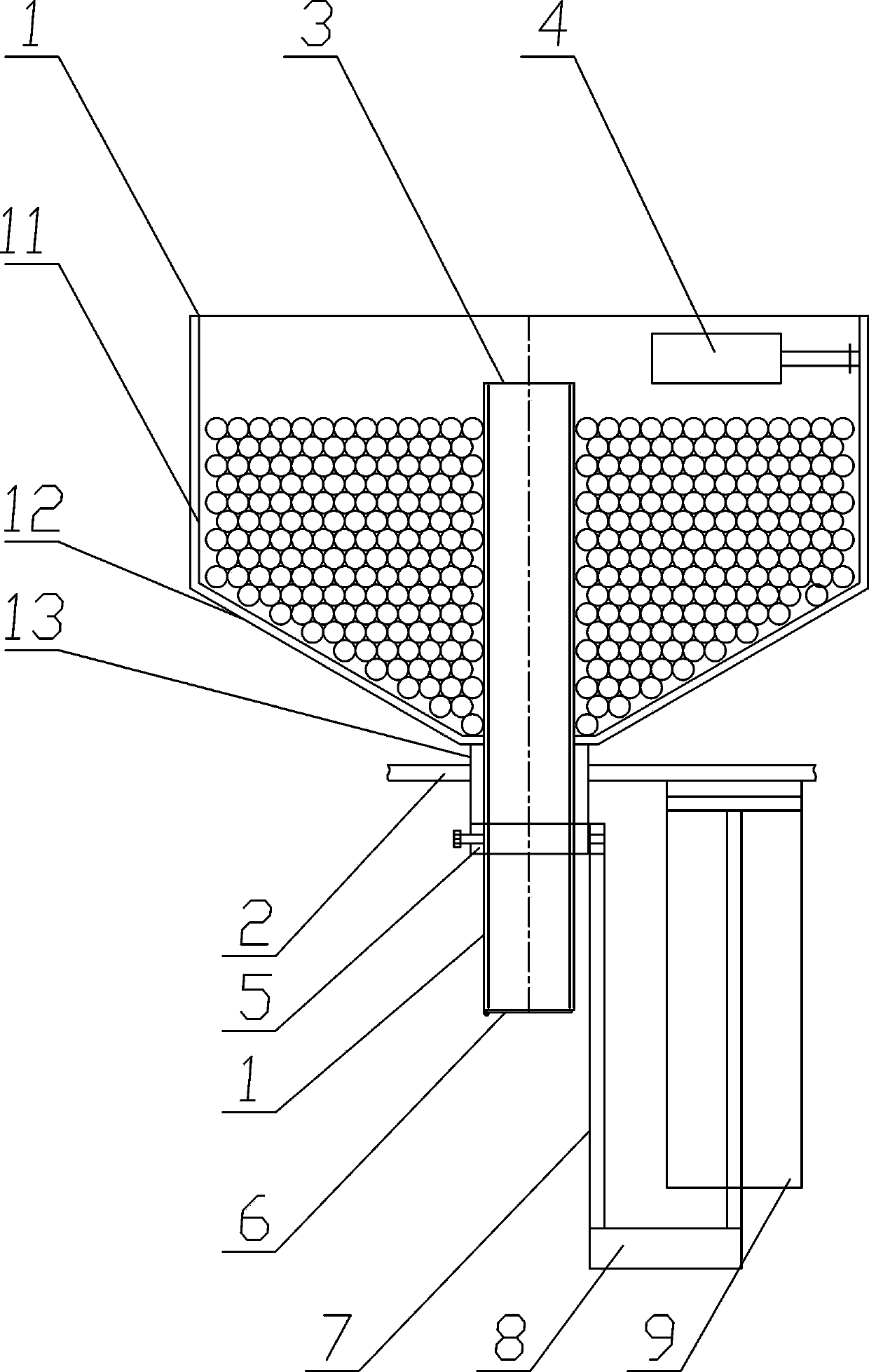

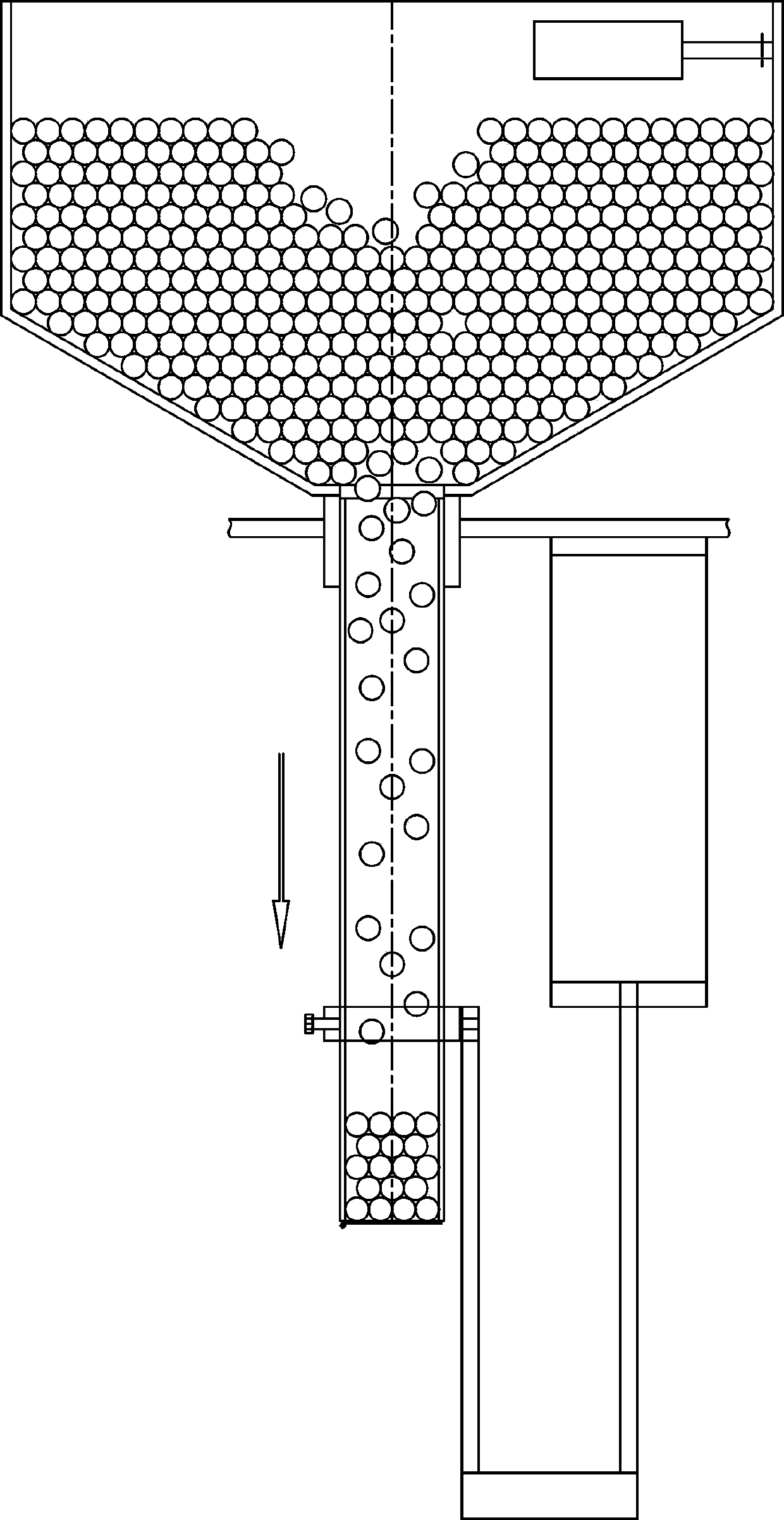

[0032] Such as figure 1 , 2 Among them, a quantitative dispensing device includes a storage hopper 1, the bottom of the storage hopper 1 is provided with a sleeve part 13, and a sliding sleeve 3 sliding along the axis of the sleeve part 13 is installed in the sleeve part 13, and the sliding sleeve 3 is driven by a driving device Drive to realize lifting and reciprocating movement, the upper end of the sliding cylinder 3 is open, and the bottom of the sliding cylinder 3 is provided with an openable valve device 6;

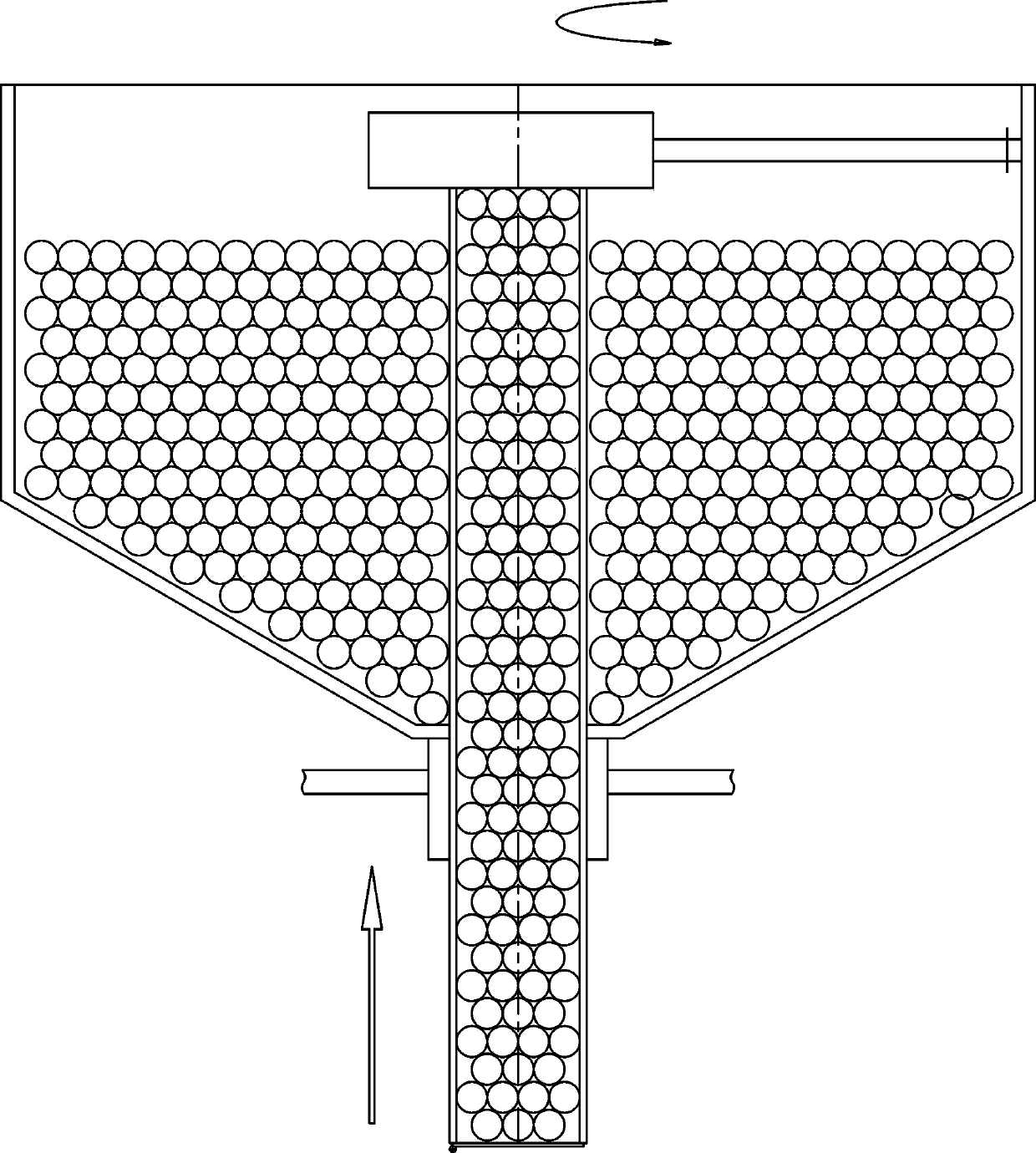

[0033] Such as image 3 Among them, a scraper device 4 is also provided. When the slider 3 is at the upper limit point, the scraper device 4 is used to scrape the upper end of the slider 3 level. With this structure, quantitative packaging of materials in the sliding cylinder 3 can be realized.

[0034] The preferred solution is as figure 1 , 2 Among them, the outer wall of the sliding cylinder 3 is provided with a transmission ring 5, and the transmission ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com