Optical module, backlight module and display device

A technology of optical components and optical films, applied in optical components, optics, lamination devices, etc., can solve problems such as easy scratches or foreign objects, difficulty in backlight module assembly, and reduced production efficiency, so as to improve the yield rate , Improve light source utilization and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

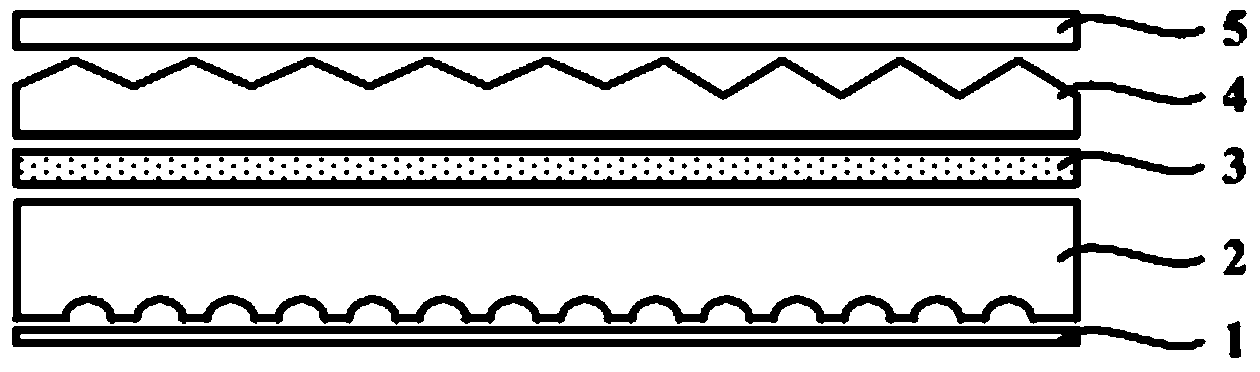

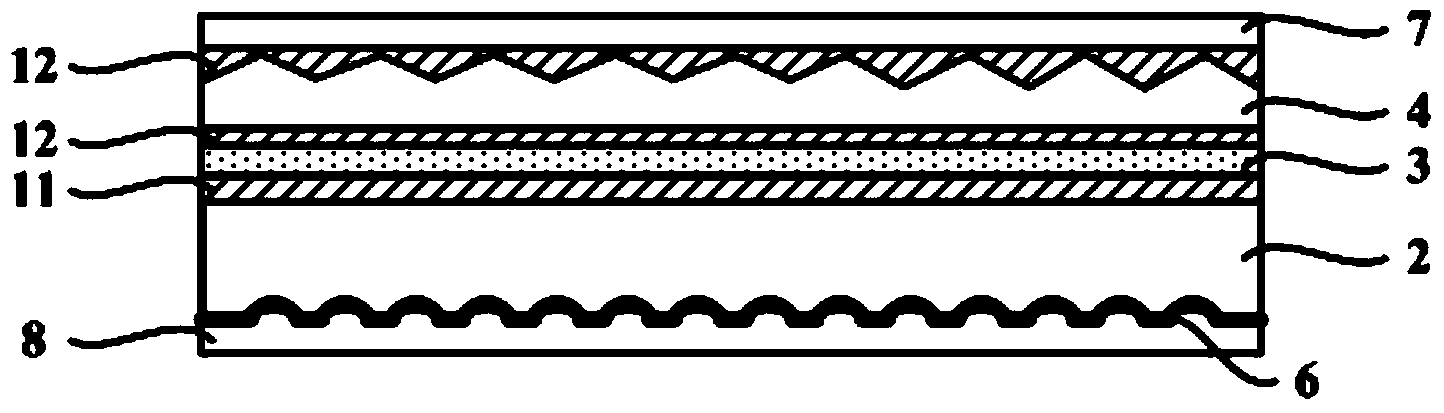

[0043] Preferably, the first implementation mode: please continue to refer to figure 2 As shown, the optical film set includes a diffusion sheet 3, a first protection sheet 7, and a prism sheet 4 between the diffusion sheet 3 and the first protection sheet 7;

[0044] The light guide plate 2 and the diffusion sheet 3 are bonded and fixed through the first transparent adhesive layer 11 .

[0045] In this embodiment, each optical film in the optical film group is bonded through the second transparent bonding layer 12, and the light guide plate 2 and the optical film group are bonded through the first transparent bonding layer 11, so that the optical The assembly becomes an all-in-one optical assembly.

[0046] Preferably, the second embodiment: as image 3 as shown, image 3 The structural diagram of the optical assembly provided for the second embodiment of the present invention, the light guide plate is a holographic light guide plate 21 with a diffusion function; the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com