Turnover supporting leg mechanism, turnover sleeping berth and passenger car with turnover sleeping berths

A technology for laying boards and fixing boards, which is applied to vehicles used for freight transportation, vehicles including people's living utensils, motor vehicles, etc., and can solve the problems of not being suitable for sleeper buses, complicated leg structure, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

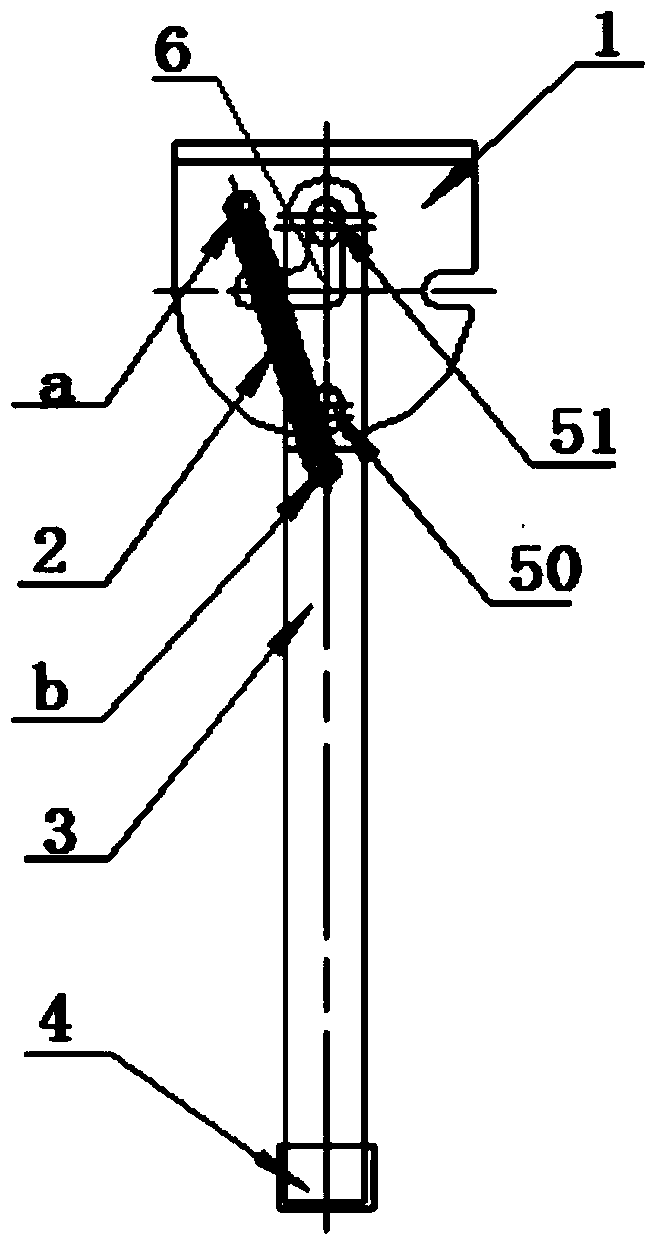

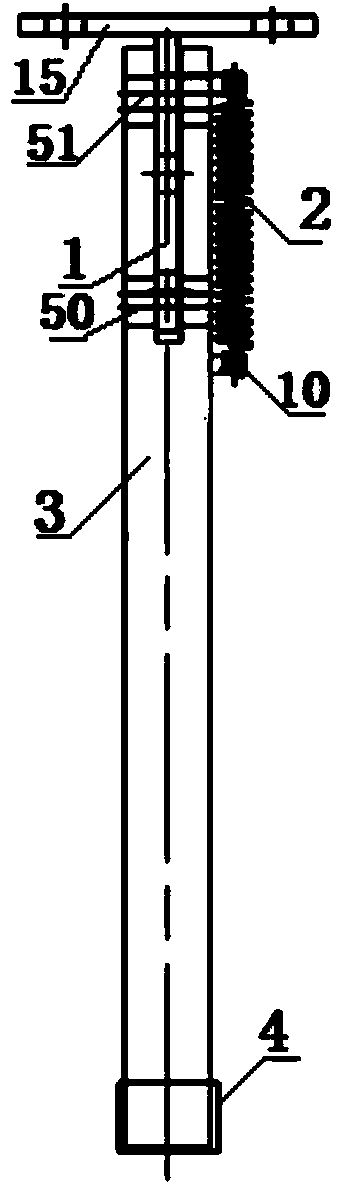

[0026] An embodiment of a turnover leg mechanism of the present invention: as figure 1 As shown in -4, it includes a leg fixing frame and a leg body 3. The leg fixing frame is composed of a fixing seat 15 and a fixing plate 1 that are vertically connected to each other, wherein the fixing seat 15 is used to be connected to the flipping leg mechanism Fixedly connected, the fixed plate 1 is used to connect with the leg body 3 .

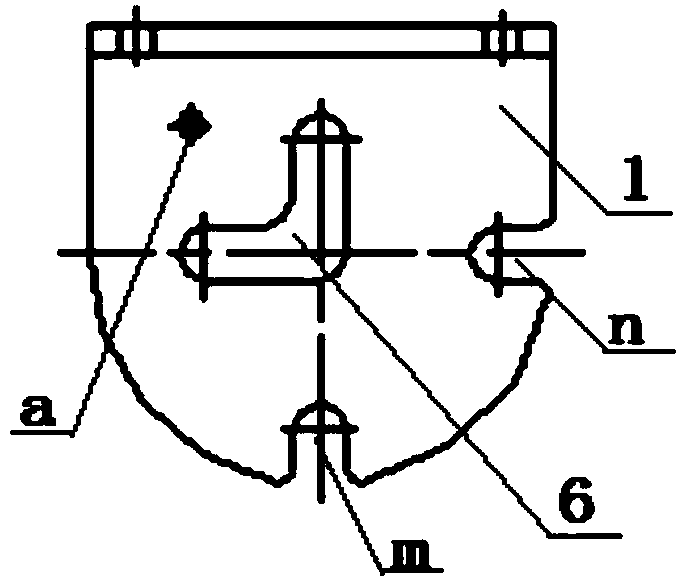

[0027] In this embodiment, the fixed plate 1 is a bow-shaped plate with straight edges and arc edges. The fixed plate 1 is provided with an L-shaped chute 6 with horizontal and vertical edges. The vertical edges of the L-shaped chute 6 and The connection point of the horizontal edge is located at the center position of the arc edge of the fixed plate 1, and the horizontal edge and the vertical edge length of the L-shaped chute 6 are equal in length, and the arc edge of the fixed plate 1 is on the horizontal edge and the vertical edge of the L-shaped chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com