Wire harness routing device for sliding seat

A wiring device and wire harness technology, which can be applied to movable seats, vehicle seats, special positions of vehicles, etc., can solve the problems of time-consuming, space limitation, and cost increase, and achieve the effect of reducing possibility and preventing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0035] Figure 1 to Figure 7 The first embodiment of the present invention is shown.

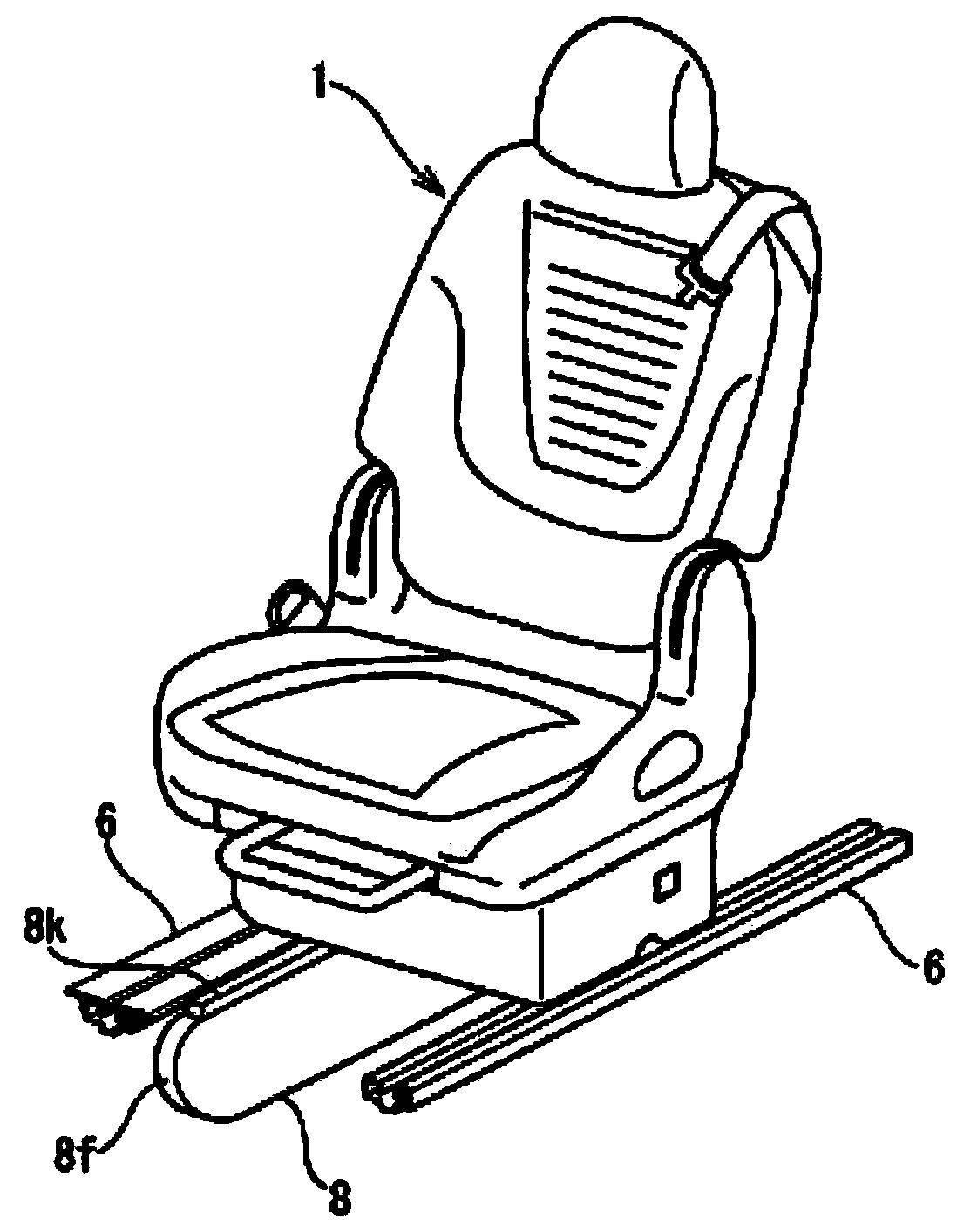

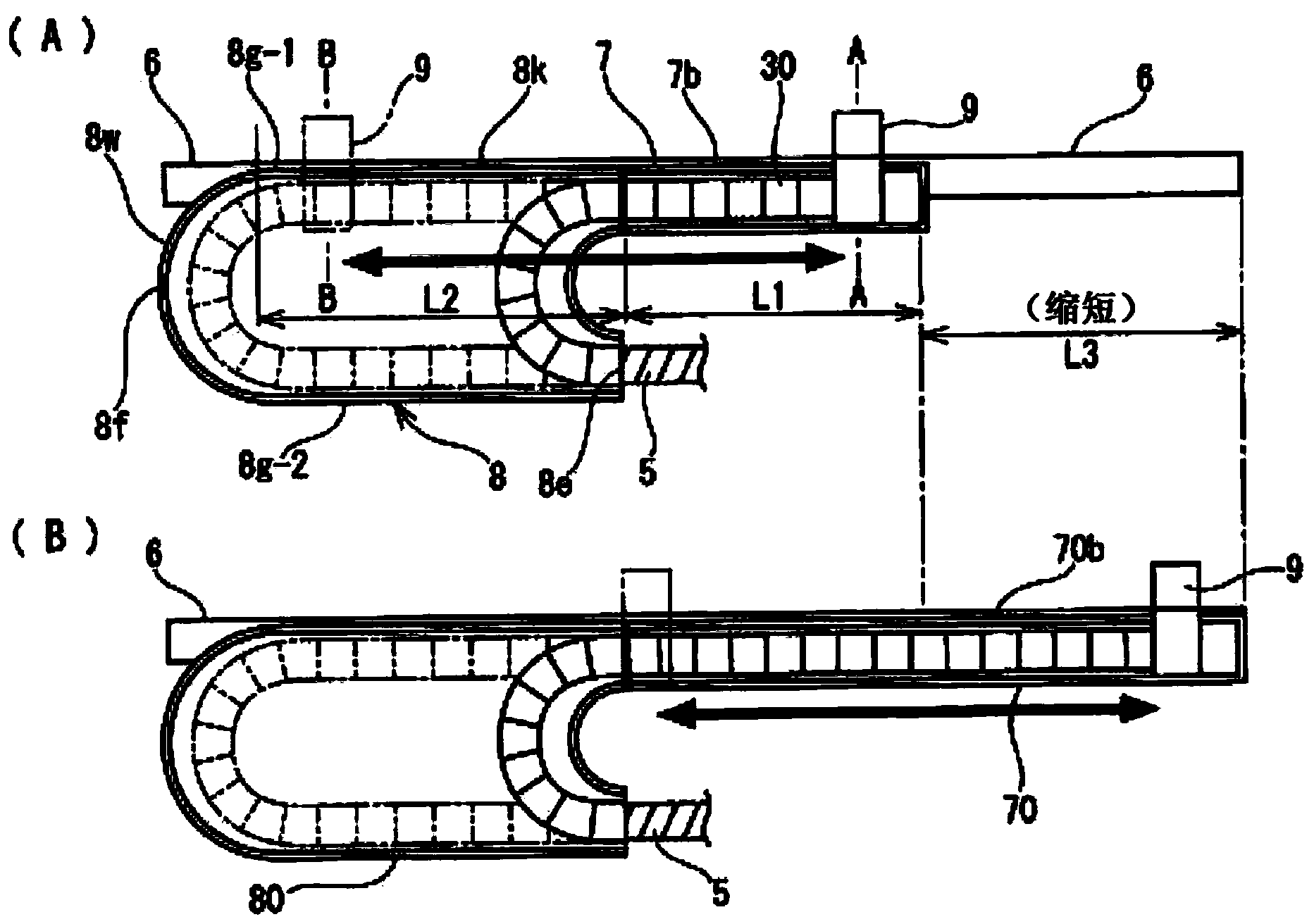

[0036] like figure 1 As shown, in order to supply power to electrical components (not shown) mounted on the sliding seat 1 mounted on the passenger side of the automobile, the sliding seat 1 is supplied from the floor side as shown in FIG. figure 2 The wire harness 5 (hereinafter, referred to as the seat wire harness 5 ) is wired in the manner shown.

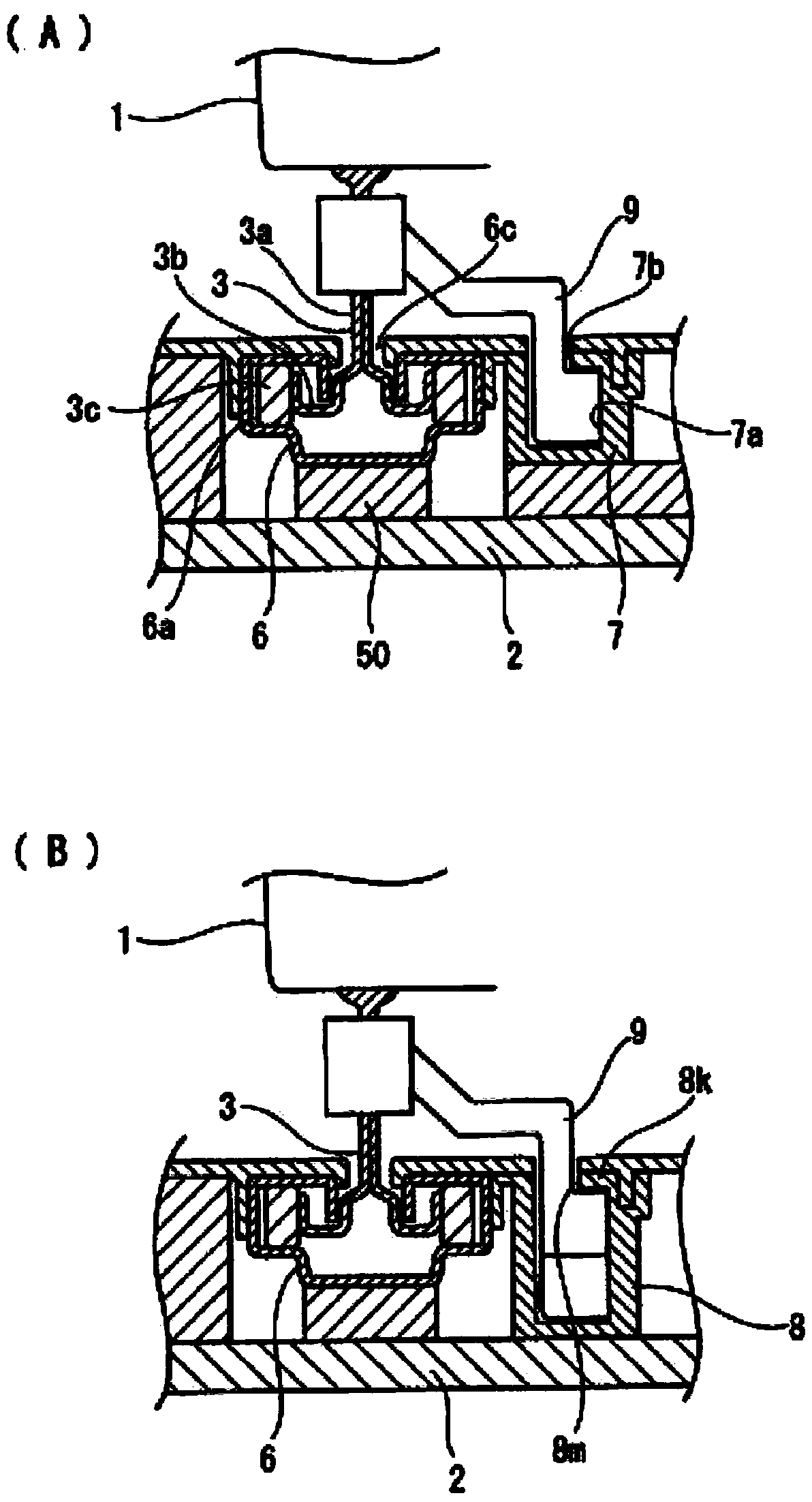

[0037] like image 3 As shown, a pair of left and right seat feet 3 are arranged on the lower surface of the sliding seat 1, and each seat foot 3 is slidably installed on a pair of left and right seat guide rails 6, and the left and right pair of seat guide rails 6 are supported by The stand 50 is mounted on the floor 2 . In each seat rail 6, the shaft portion 3a of the seat leg portion 3 protruding below the seat surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com