Operation control method for sewage treatment

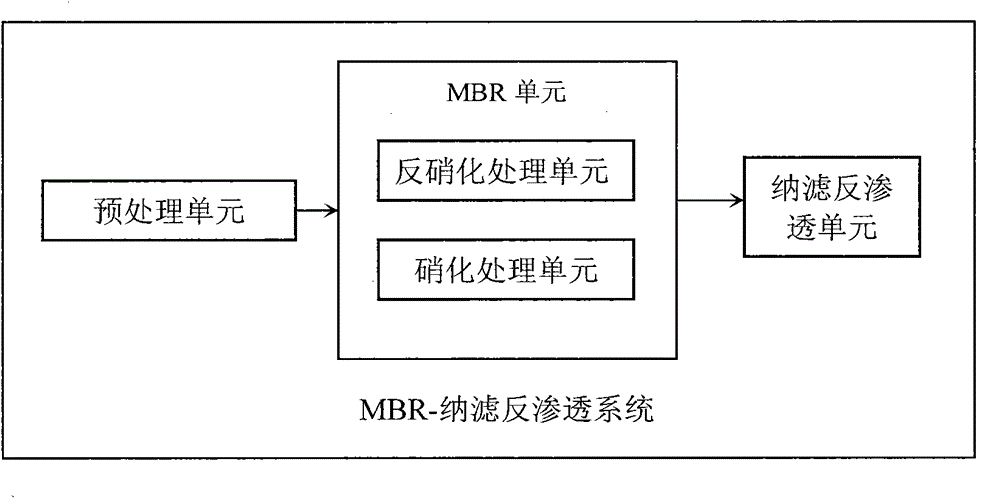

A technology for operation control and sewage treatment. It is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, and comprehensive factory control. It can solve the problems of energy consumption, low efficiency and low level of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate this scheme, the following explains this scheme by describing a specific sewage treatment system and its control process.

[0019] In an actual sewage treatment system, the central control unit used to realize the operation control of sewage treatment is realized by the PLC module, and the adjustment unit used to realize the operation control is composed of an electric control valve, a frequency conversion fan, a water pump and a solenoid valve.

[0020] Among them, the function of the electric control valve is to change the size of the flow area of the pipeline, and then play a role in regulating the flow of the pipeline. The monitoring signal of the control unit to the electric control valve is at least:

[0021] 1) The valve is fully open and fully closed;

[0022] 2) The action status of valve general fault protection;

[0023] 3) The state of the valve operation process;

[0024] 4) Valve manual and remote control status;

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com